Three-dimensional adjustable fixing device of automatic welding gun

A fixed device and mobile device technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficulty in ensuring welding quality, inability to realize accurate adjustment and fine-tuning of welding torch, and inability to adjust the position and angle of welding torch accurately and stably , to achieve the effect of improving welding quality, adjusting movement stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

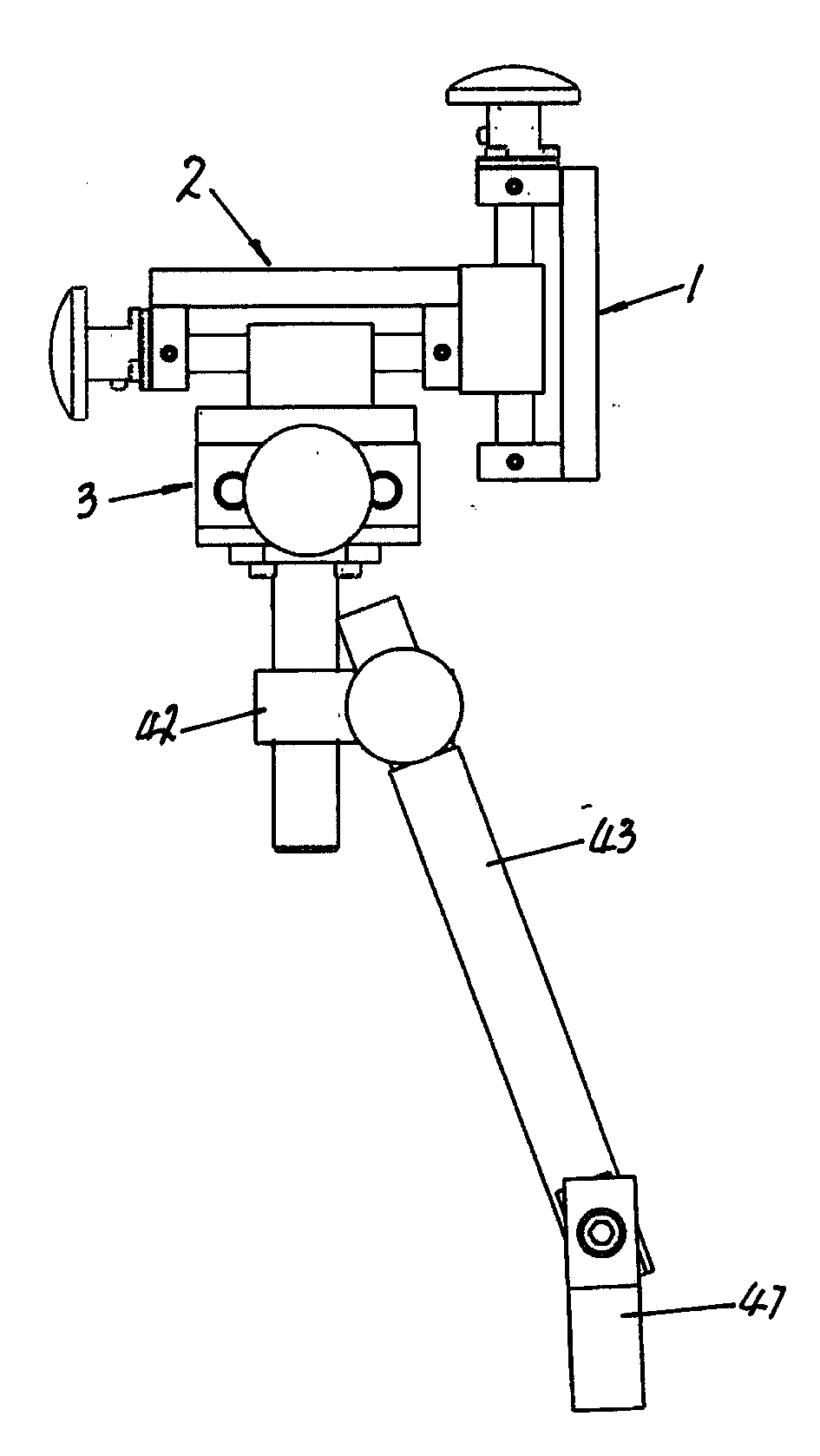

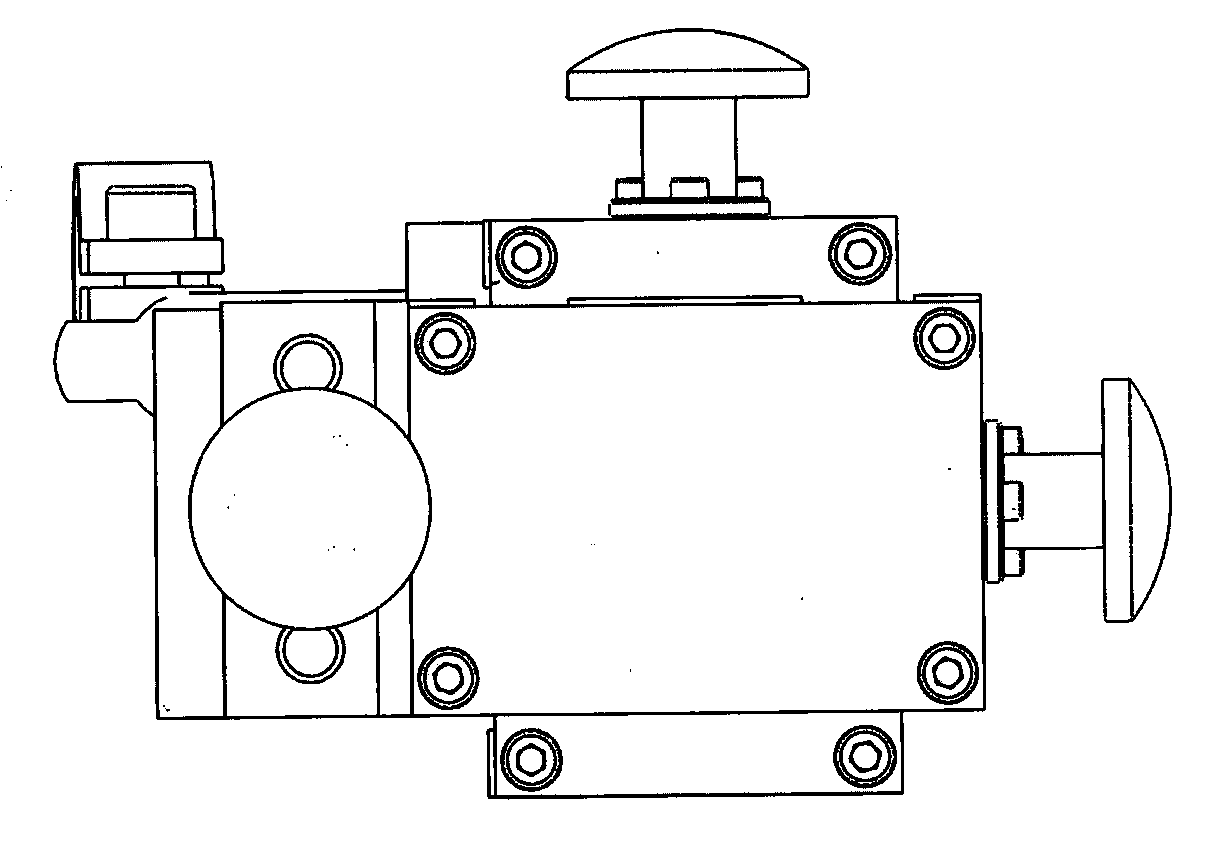

[0014] The invention of the present invention is composed of the upper and lower mobile devices 1. The left and right movement device 2. The front and rear movement device 3. The rotating connecting rod device 4, the upper and lower movement device 1. Figure 10 It is shown in the C -shaped rack 10, slider 11, slider guide rod 12A, 12B, transmission screw 13, transmission screw rotating handle 14, slider guide rod 12A and 12B are fixed to C -shaped rack 10 10On the left and right ends on the shelf of 10A and 10B, the slider shaft holes are opened on the slider 11 and the slider is 12A, 12B sliding and the installation connection, and the transmission screw 13 and the end frame 10B positioning of the C -shaped shelf 10B positioning rotation coordinationConnect, the threaded screw 13 and the snail hole opened on the slider 11 with the connection to drive the slider 11 in the slider's shot rod 12A and 12B sliding movement;The slider 11 is fixed; the movement of the front and rear move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com