Modified LiNi1/2Mn3/2O4 cathode material prepared by coating with lithium ion conductor Li2MO3 (M=Ti, Si or Zr) and preparation method thereof

A positive electrode material, lithium ion technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems such as the negative impact of high rate performance of materials, and achieve simple and controllable coating process, low cost, and improved high temperature cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

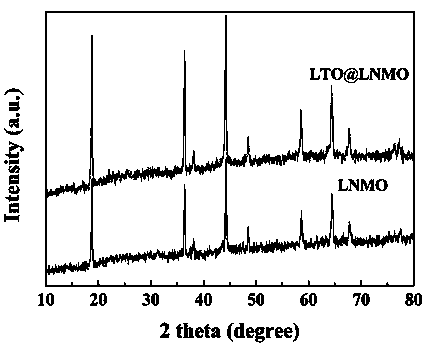

Embodiment 1

[0026] First, nickel acetate, manganese acetate, lithium acetate and citric acid are dissolved in water sequentially according to Ni:Mn:Li:citric acid=1:3:2.06:6 (molar ratio), slowly evaporated at 80 ℃, and sintered at 750 ℃ Preparation of nanoscale LiNi in 15 h 0.5 mn 1.5 o 4 Cathode material (referred to as: LNMO). Then, it was dispersed in ethanol to form a suspension with constant stirring. Under the condition of stirring speed of 80 rpm / min, according to Li 2 TiO 3 To account for 5% of the mass fraction of the coated positive electrode material, tetrabutyl titanate (TBOT) was added. After 0.5 h, a small amount of 28% ammonia water (the mass ratio of TBOT to ammonia water = 5:1) was added, the stirring speed was kept at 80 rpm / min, and the temperature was 40 °C for hydrolysis reaction, and the solvent was evaporated to dryness. Finally, lithium hydroxide was added according to the stoichiometric ratio and mixed evenly, and calcined at 750 °C for 4 h to obtain Li 2...

Embodiment 2

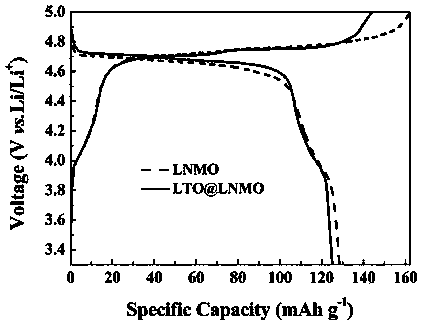

[0028] First, lithium carbonate, nickel oxide, and manganese dioxide were mixed according to Li:Ni:Mn=2.1:1:3 (molar ratio), and sintered at 800 °C for 10 h to prepare LiNi 0.5 mn 1.5 o 4 Cathode material. Then, it was dispersed in ethanol to form a suspension with constant stirring. Under the condition of stirring speed of 100 rpm / min, according to Li 2 TiO 3 Add tetrabutyl titanate (TBOT) in proportion to 3% of the mass fraction of the coated positive electrode material. After 1 h, add a small amount of 28% ammonia water (the mass ratio of TBOT to ammonia water = 5:1), keep the stirring speed at 100 rpm / min, and carry out the hydrolysis reaction at 40 °C, and evaporate the solvent to dryness. Finally, lithium acetate was added according to the stoichiometric ratio and mixed evenly, and calcined at 800 °C for 2 h to obtain Li 2 TiO 3 coated modified LiNi 0.5 mn 1.5 o 4 Cathode material. Comparing the coated sample with the pure phase sample: coated Li 2 TiO 3 Aft...

Embodiment 3

[0030] First, the co-precipitation method was used to prepare spherical Ni 0.25 mn 0.75 CO 3 precursor, and according to Li:Ni= 2.1:1 (molar ratio) mixed with lithium hydroxide, sintered at 800 °C for 10 h to obtain spherical LiNi 0.5 mn 1.5 o 4 Cathode material. Then, it was dispersed in ethanol to form a suspension with constant stirring. Under the condition of stirring speed of 80 rpm / min, according to Li 2 TiO 3 Add tetrabutyl titanate (TBOT) in proportion to 1% of the mass fraction of the coated positive electrode material. After 1 h, a small amount of 28% ammonia water (the mass ratio of TBOT to ammonia water = 5:1) was added, the stirring speed was kept at 80 rpm / min, and the temperature was 40 °C for hydrolysis reaction, and the solvent was evaporated to dryness. Finally, lithium oxalate was added according to the stoichiometric ratio and mixed evenly, and calcined at 800 °C for 3 h to obtain Li 2 TiO 3 coated modified LiNi 0.5 mn 1.5 o 4 Cathode material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com