Silicon wafer fully-automatic feeding/discharging manipulator and movement trajectory control method thereof

A fully automatic technology for loading and unloading, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low conversion efficiency, low flexibility, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

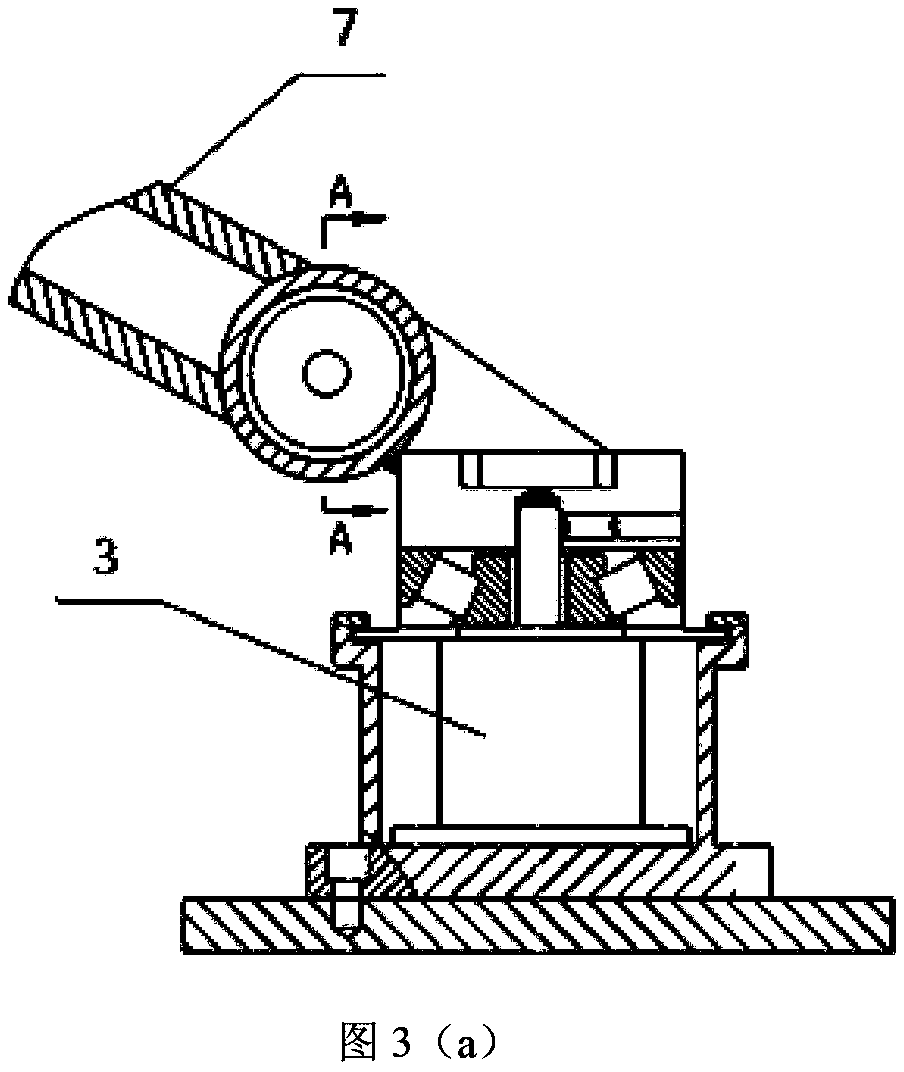

[0030] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a mounting base 1, a shoulder joint 6, a large arm 7, a small arm 9, and a claw 11 for grabbing silicon wafers onto multi-channel solar cell processing equipment. 7 and the forearm 9 are connected through the elbow joint 10, the forearm 9 and the claw 11 are connected through the wrist joint 10, the shoulder joint 6 is installed on the installation base 1, and the motor is installed on the shoulder joint 6. seat 4, the motor mounting seat 4 is installed with a servo motor 3 that drives the motor mounting seat 4 to rotate around its own motor shaft relative to the mounting base 1, and the motor mounting seat 4 is also equipped with a servo motor that drives the arm 7 The first biaxial motor 5 that rotates around its own motor shaft relative to the motor mounting seat 4; the second biaxial motor 5 that drives the small arm 9 to rotate around its own motor shaft relative to the big arm 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com