A test equipment for star service subsystem based on fpga framework

A test equipment and sub-system technology, applied in the field of testing, can solve problems such as easy failure, inconvenience in carrying and handling, and difficulty in upgrading, achieve good compatibility and upgradeability, improve test stability, and reduce wiring complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

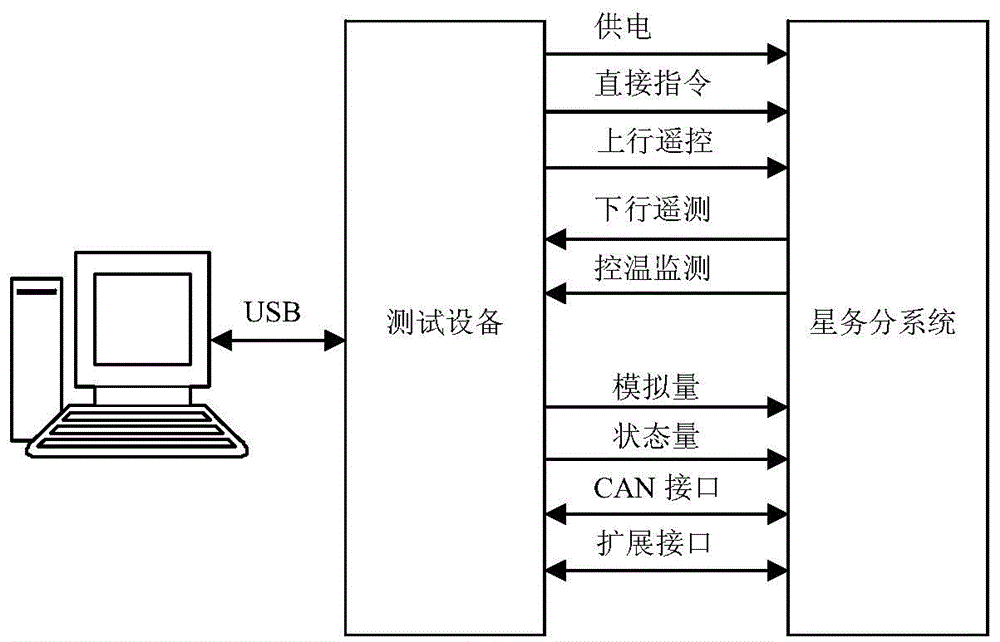

[0023] like figure 2 As shown, the system can generate various excitation signals required by the star service subsystem, and analyze various response signals generated by the star service subsystem. The system uses USB communication with the host computer.

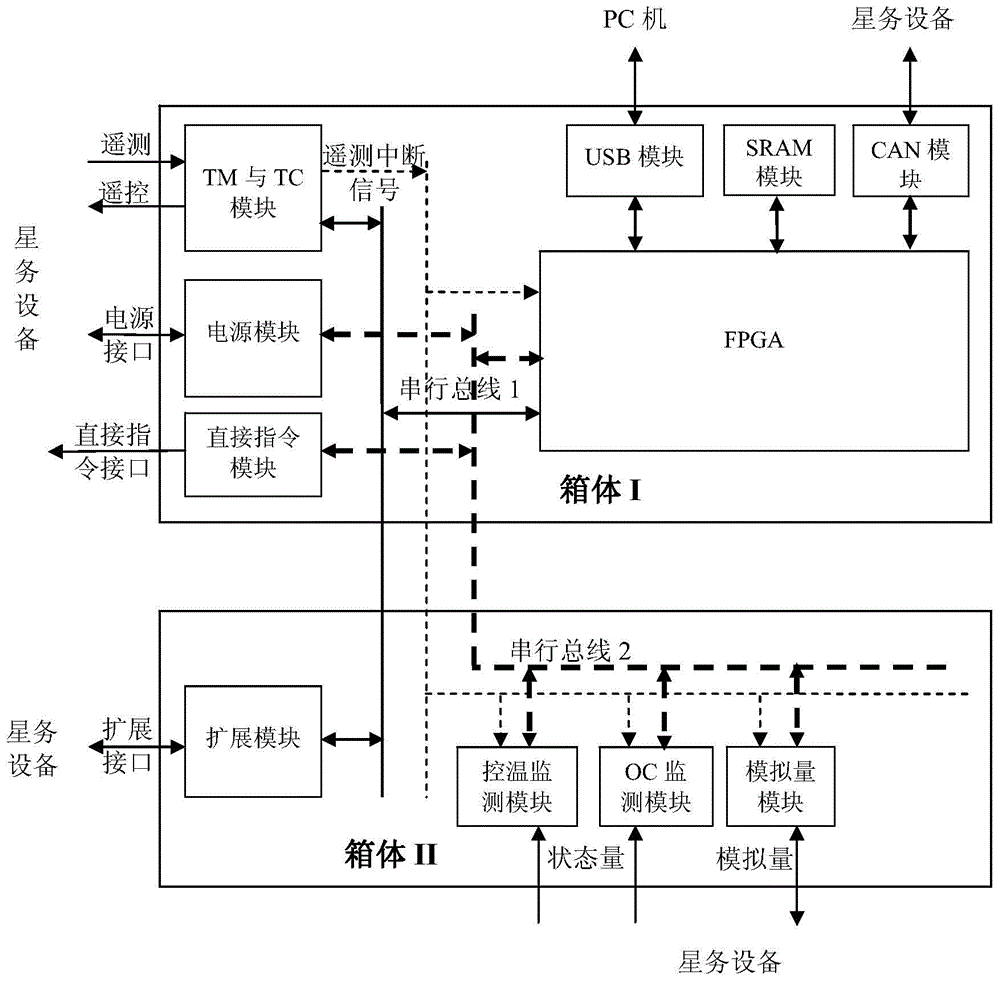

[0024] like image 3 As shown, this system adopts the main and auxiliary double box structure design according to the characteristics of star service equipment testing to meet the needs of star service test. The hardware circuit system adopts a modular design, takes FPGA as the core, and uniformly schedules the work of each module. The modules are connected in a system by a serial bus, and the serial bus 1 is used to transmit the telemetry signal of the satellite and the remote control of the satellite. Instructions, the serial bus 2 is used to transmit the response signals of star service equipment and module excitation generation instructions. Through the serial bus, the modules are organically combined and independe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com