Optical fiber beam combiner and preparation method thereof

An optical fiber combiner and optical fiber technology, applied in the field of optical fiber, can solve the problems of poor reverse isolation performance of lasers, etc., and achieve the effects of light weight, simple manufacturing process, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

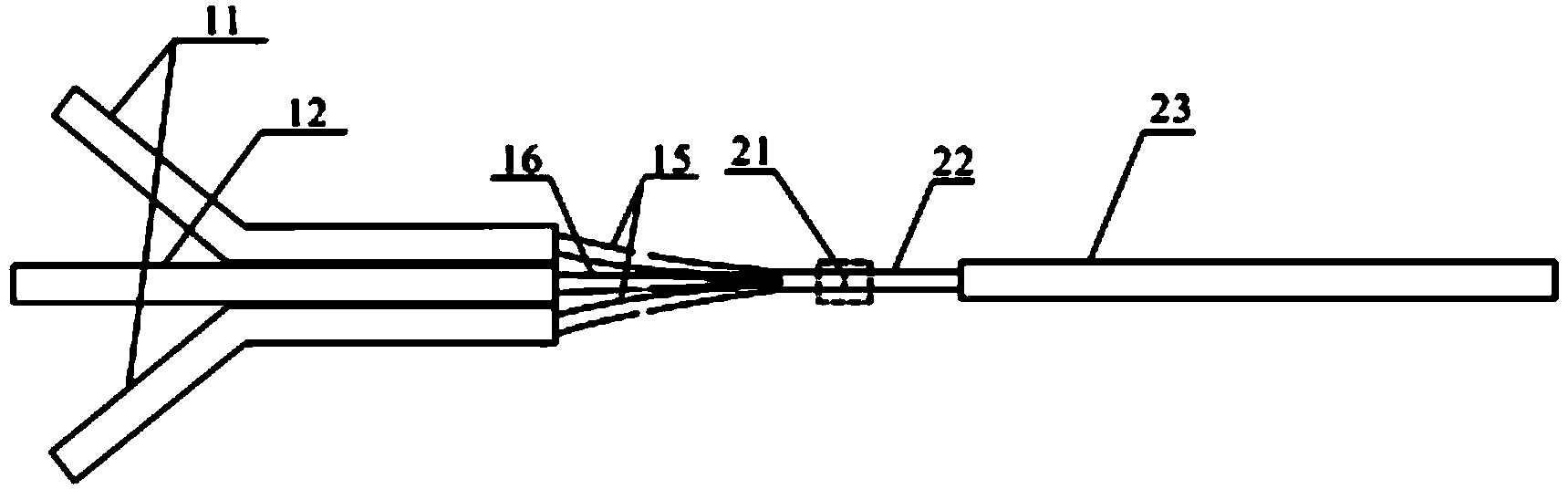

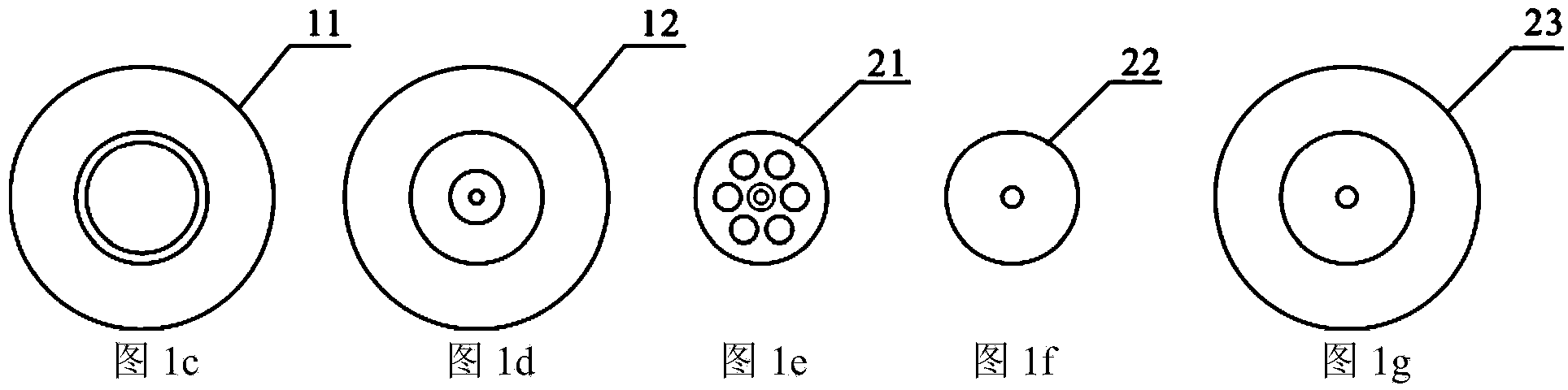

[0039] Such as Figure 1a-Figure 1g As shown, the (6+1)×1 end-pumped fiber combiner is taken as an example to illustrate the structure and method of the present invention, and the following is also applicable to various end faces such as (N+1)×1 (1≤N≤18) , Side-pumped fiber combiner, specific input and output fibers can be configured according to needs.

[0040]The fiber combiner includes an input multimode fiber 11, an input signal fiber and an output double-clad fiber 23, a small cladding is arranged between the core of the input signal fiber and the cladding closest to the core, and a built-in small cladding The bare fiber 16 of the input signal fiber and the bare fiber 15 of the input multimode fiber are fused and tapered, and then fused with the bare fiber 22 of the output double-clad fiber.

[0041] The parameters of the input multimode fiber 11 are: core / cladding / coating diameters are 105 / 125 / 250um respectively, and the numerical aperture is 0.22; the parameters of the...

Embodiment 2

[0045] Such as Figure 2a-Figure 2h As shown, the fiber combiner includes an input multimode fiber 11, an input signal fiber and an output double-clad fiber 23, and the input signal fiber is composed of the bare fiber 13 of the conventional input signal fiber 17 fused with the bare fiber of the transition fiber, A small cladding is provided between the core of the transition fiber and the cladding closest to the core, and the bare fiber of the transition fiber is fused with the bare fiber of the input multimode fiber and then fused with the bare fiber of the output double-clad fiber.

[0046] The parameters of the input multimode fiber 11 are: core / cladding / coating diameters are 105 / 125 / 250um respectively, and the numerical aperture is 0.22; the parameters of the conventional input signal fiber 17 are: core / cladding / coating The diameters are 20 / 125 / 250um respectively, and the numerical aperture is 0.06; the parameters of the transition fiber 13 are: the diameters of the core / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com