PCB limiting and testing fixture

A technology for PCB boards and test fixtures, applied in the field of fixtures, can solve the problems of crushed test points, poor air blowing effect, residual dust and waste chips, etc., to achieve high safety and reliability, good air blowing effect, and improve processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

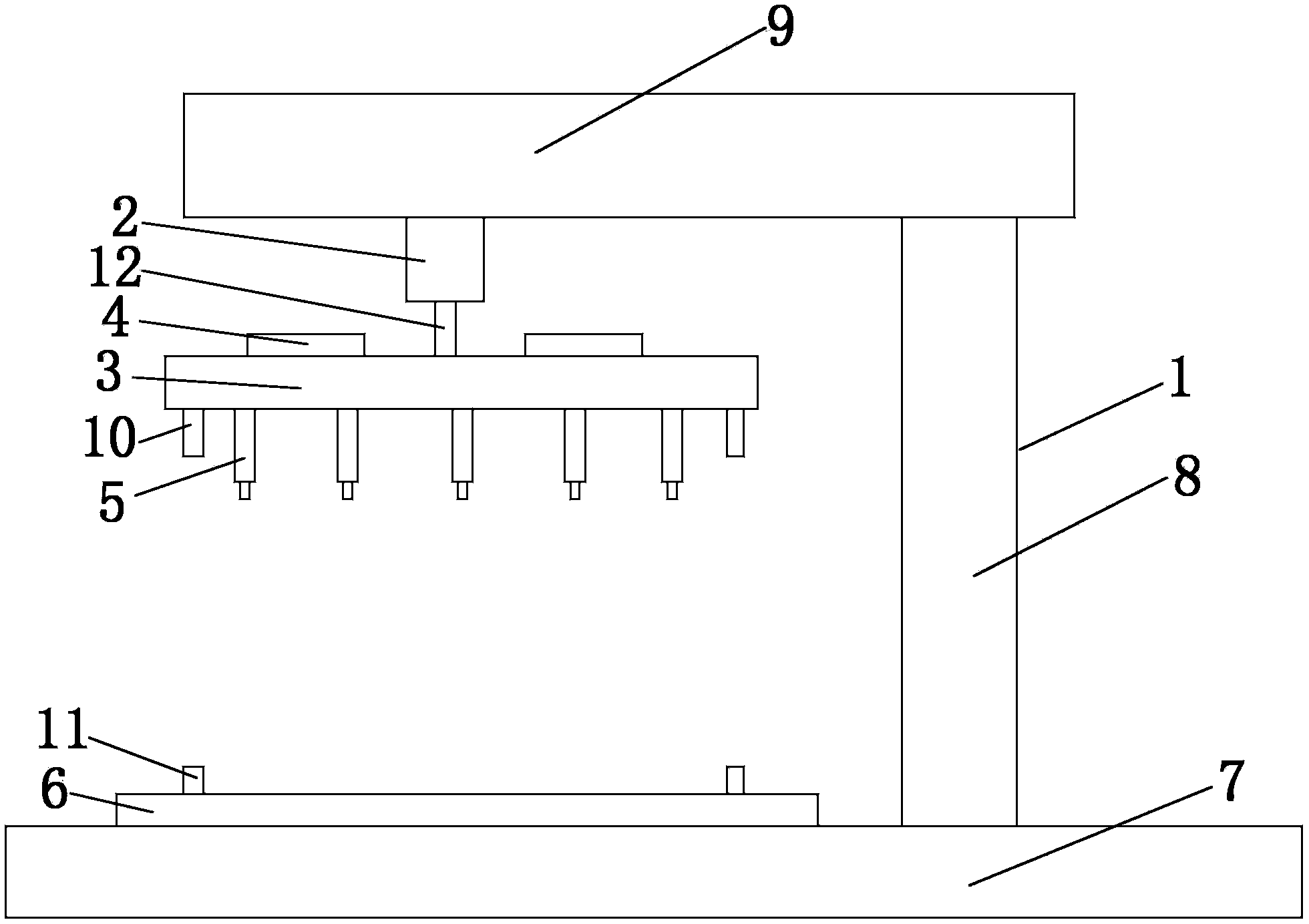

[0014] like figure 1 As shown, a PCB board limit test fixture includes a bracket 1, a cylinder 2, a moving plate 3, a blower 4, a probe 5 and a carrier plate 6, and the bracket 1 includes a base 7, a support beam 8 and a top plate 9, A supporting beam 8 is arranged on the top of the base 7, a top plate 9 is arranged on the top of the supporting beam 8, a carrier plate 6 is arranged on the top of the base 7, and a cylinder 2 is arranged on the bottom of the top plate 9, the cylinder rod 12 of the cylinder 2 and the moving plate 3 connection, the moving plate 3 is provided with several rows of through blowing holes, two blowers 4 are arranged on the top of the moving plate 3, and several probes 5 are connected to the bottom of the moving plate 3, and the probes 5 face The PCB board located in the carrier board 6 .

[0015] On the bottom of the moving plate 3 , upper ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com