Transformer coil turn-to-turn short circuit intelligent tester

A technology of transformer coil and inter-turn short circuit, which is applied to instruments, measuring electricity, measuring devices, etc., can solve the problems of reducing production efficiency, transformer operating life and power supply safety, and increasing production costs, so as to improve production efficiency and save manpower. The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

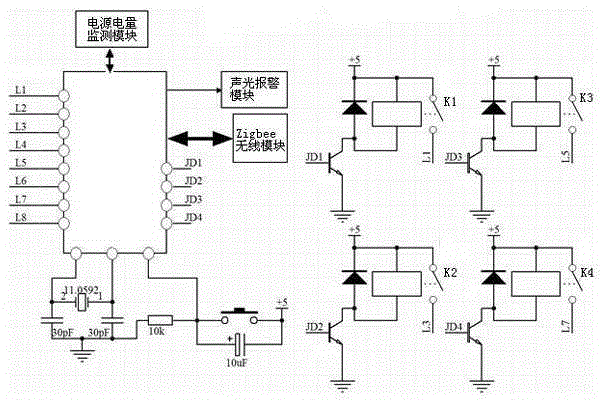

[0018] At present, in the winding of transformer coils, the most common number of parallel coils is 8. The following takes 8 parallel coils as an example to illustrate the implementation process of the present invention:

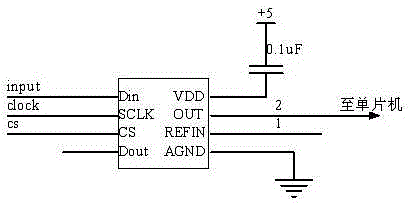

[0019] Such as figure 1 As shown, a transformer coil turn-to-turn short circuit tester includes a control module 1, an inspection module 2, a power supply module 3, an acousto-optic alarm module 6, a power supply power monitoring module 4 and a wireless transceiver module 5, and the control module 1 includes a single-chip microcomputer ,Such as figure 2 As shown, the inspection module 2 includes four relay control circuits connected to the output terminals of the single-chip microcomputer. The input terminals of the single-chip microcomputer are provided with 8 connection terminals L1-L8 for connecting wire turns, and the other input terminals are connected to the power supply module 3. Input The output end is connected to the wireless transceiver module 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com