Motor variable-frequency driver aging test device and test method thereof

A variable frequency drive, aging test technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of energy consumption and occupied space reduction, load aging consumption is large, no-load aging can not be fully exposed, etc., to achieve space occupation Small size and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

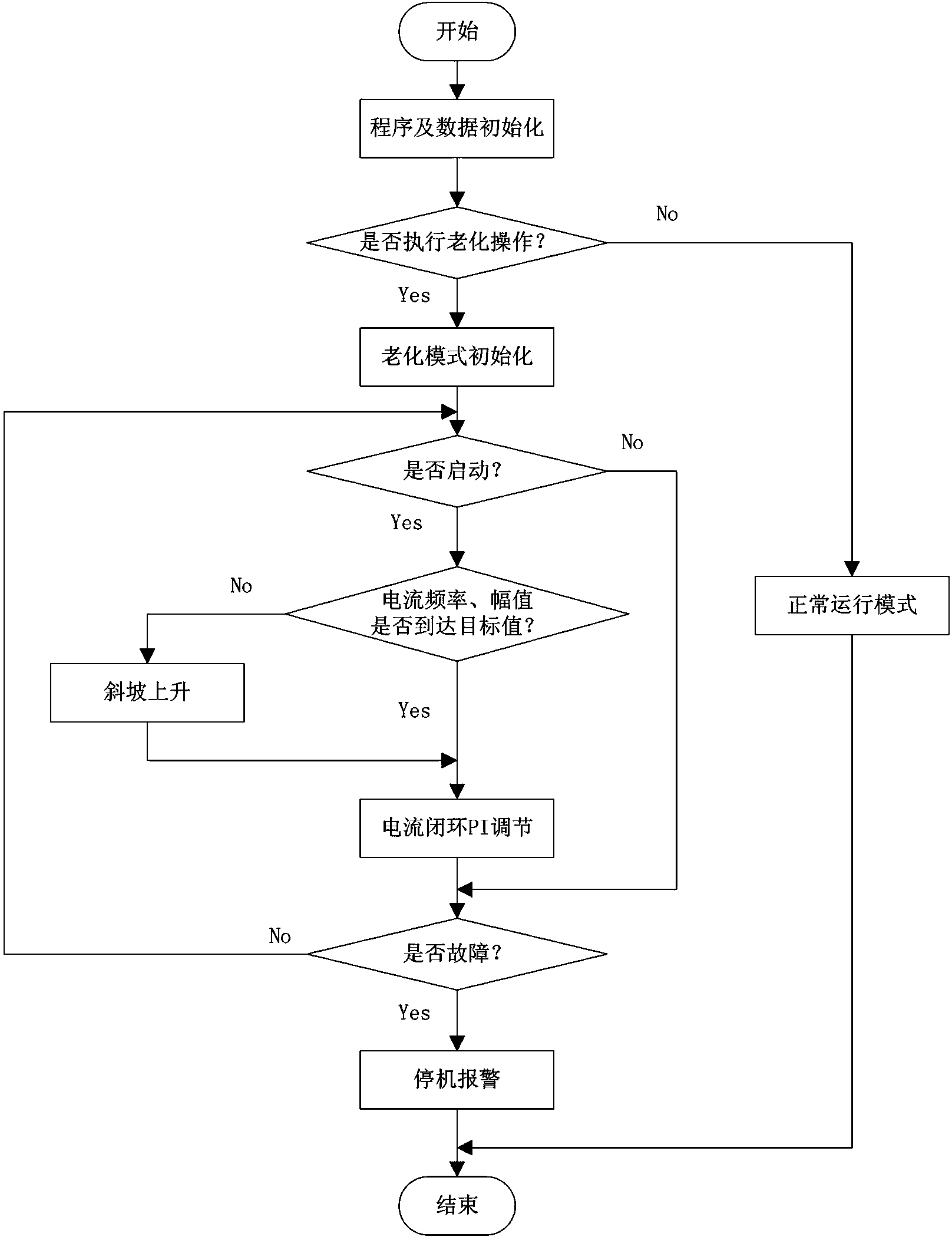

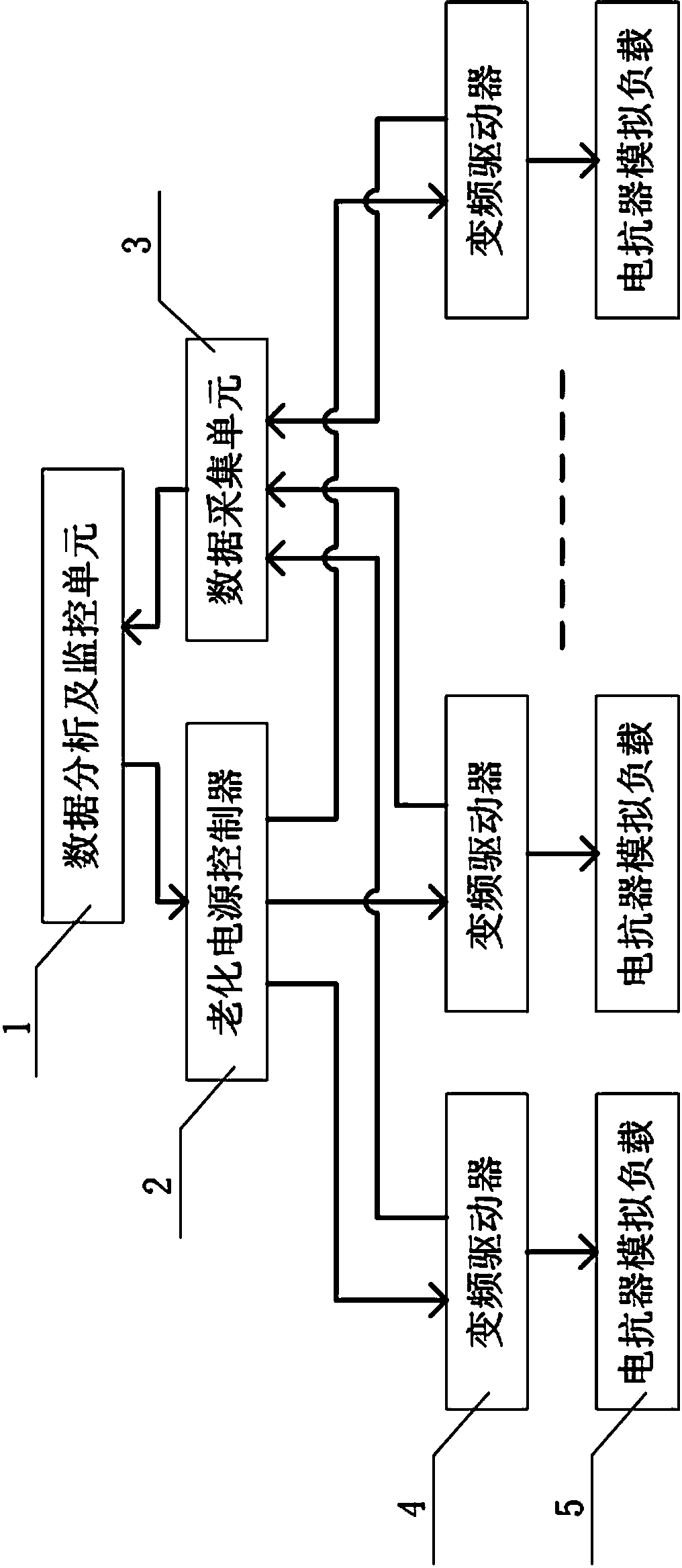

[0020] Such as figure 1 As shown, a motor variable frequency drive 4 aging test device includes a data acquisition unit 3 for collecting various data of the variable frequency drive 4 in the aging test process, and an aging power control unit that controls the power supply to the variable frequency drive 4 and the load. 2, read the data of the data acquisition unit 3 and the data analysis and monitoring unit 1 that sends control instructions to the aging power controller 2, the load is a reactor simulation load 5, and the reactor simulation load 5 terminals with the same name are connected to each other, thereby simulating At the middle point of the motor, the remaining three taps of the reactor simulation load 5 are connected to the three-phase (UVW three-phase) output end of the variable frequency drive 4 . In order to simulate the effect of running ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com