Rate gyroscope calibrating method

A technology of rate gyroscope and calibration method, which is applied in the direction of measuring devices and instruments, and can solve the problems such as the complexity of the rate gyroscope error calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific steps of the rate gyro calibration method of the present invention are as follows:

[0025] Under the room temperature condition, the experiment carried out on the 3SK-150 type non-magnetic turntable by the miniature heading and attitude measurement system of three-axis MEMS accelerometer, three-axis MEMS angular rate gyroscope and three-axis miniature fluxgate sensor is carried out as an example to the present invention illustrate. The method steps are as follows:

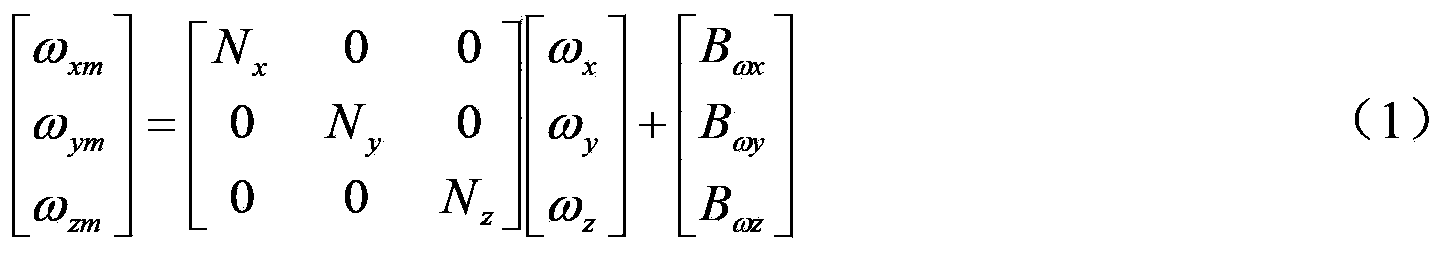

[0026] (1) Establish the error model of the rate gyroscope as follows:

[0027] ω xm ω ym ω zm = N x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com