Method for detecting roundness and sphericity of inner sphere of outer ring of knuckle bearing

A joint bearing and detection method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate measurement data and damage to the product surface, etc., and achieve the effects of high detection accuracy, wide application range and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for detecting the sphericity of the inner spherical surface of the outer ring of the joint bearing described in the embodiment of the present invention includes the following steps:

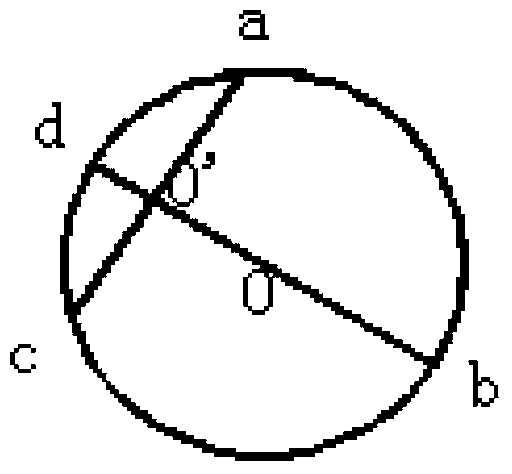

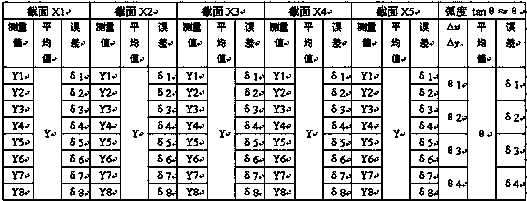

[0018] 1) To measure a certain diameter, place the measuring rod in the outer ring of the joint bearing, such as figure 1 As shown, O' is the point of the measuring rod, and the measuring rod is equipped with two sets of four measuring sensors perpendicular to each other on the same plane, and respectively measures O'a, O'b, O'c and O'd, where a, b, c , d are four measurement points on the inner spherical surface of the outer ring. According to geometric knowledge, any two chords perpendicular to each other in a circle, one of them must pass through the center of the circle, and the length is also the longest, that is, the diameter, such as figure 1 shown. Add the corresponding two measured values, take the larger measured value, that is, measure the diameter of a certain cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com