Gate valve of nuclear fuel transfer device

A transfer device, nuclear fuel technology, applied in valve device, valve operation/release device, sliding valve and other directions, can solve the problems of difficult decontamination of the shape, large operating torque, gate valve leakage, etc., to overcome the problem of poor sealing or water leakage, The effect of reducing friction and reducing the opening and closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

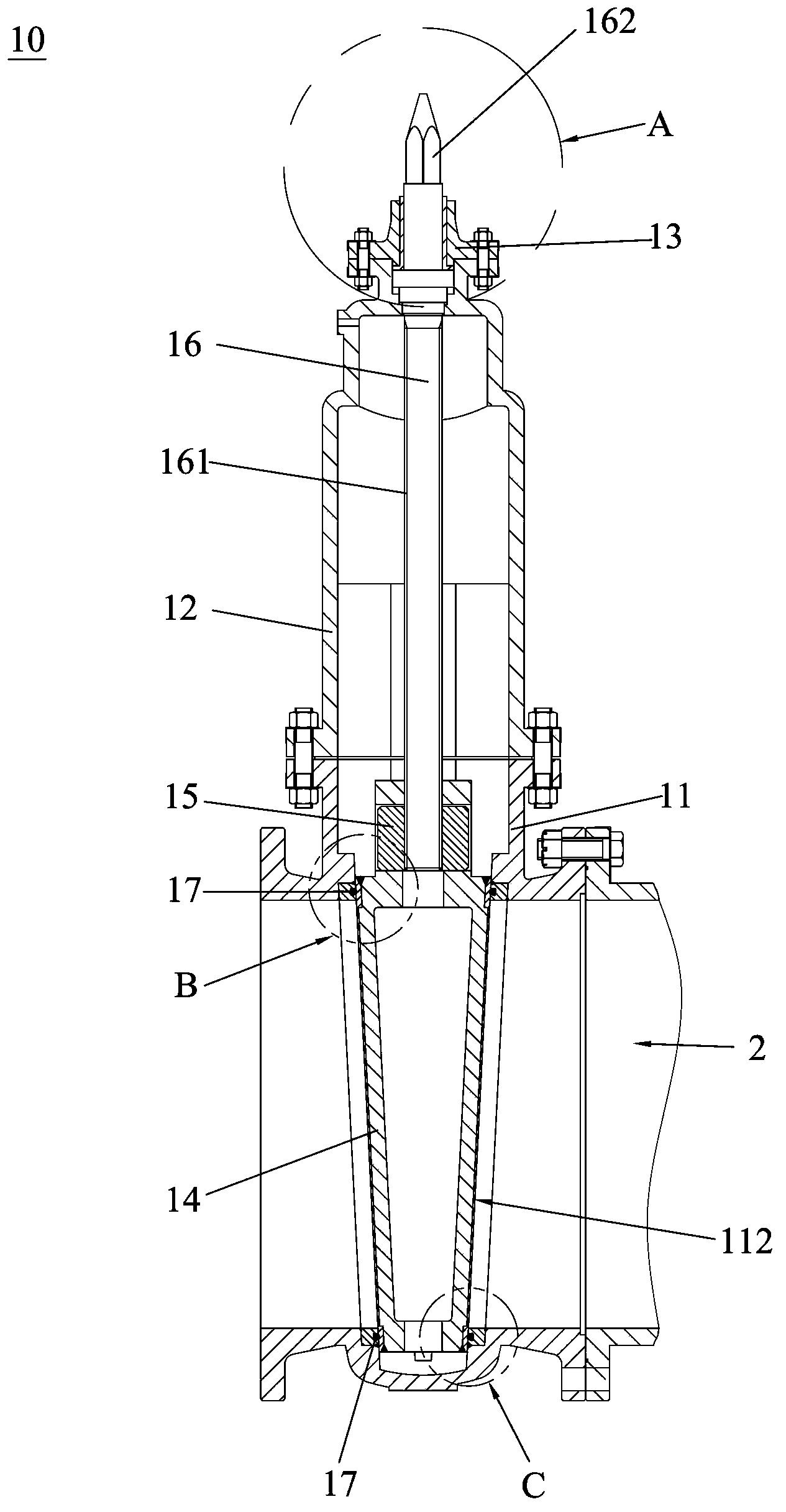

[0034] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The gate valve 1 of the nuclear fuel transfer device provided by the present invention has a simplified structure, no leakage during use, is convenient for decontamination, and has a small operating torque of a remote control lever.

[0035] Such as figure 1 , figure 2 As shown, the gate valve 1 of the nuclear fuel transfer device provided by the present invention is arranged on the nuclear fuel transfer channel 2 to open or close the transfer channel 2, and it includes a detachably connected gate valve assembly 10 and an operating rod assembly 20. On the gate valve assembly 10 A channel hole 111 is opened, and the nuclear fuel transfer track passes through the channel hole 111, so that the channel hole 111 and the transfer channel 2 are connected front and rear, and the gate valve assembly 10 is remotely controlled by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com