Transmission tensioning device

A technology of tensioning device and axial position, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. It can solve the problems of easy wear, tight half of the transmission belt, and inconvenience, so as to improve the service life and protect both sides. Even tension, fast and convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

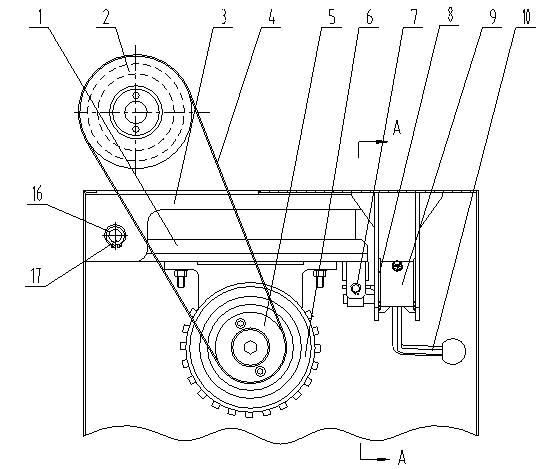

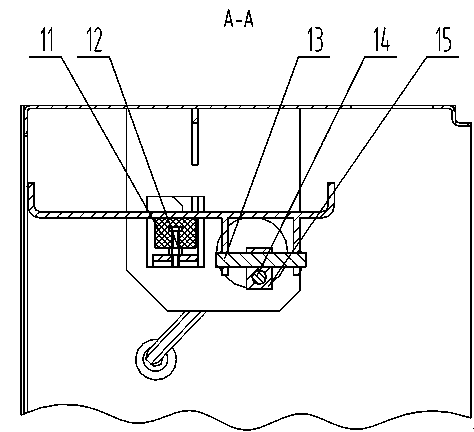

[0020] Embodiment 1: as figure 1 , 2 As shown, a transmission tensioning device includes a motor base 1, a pulley 2, a motor casing 3, a transmission belt 4, a motor pulley 5, a motor 6, a second retaining ring 7, a third retaining ring 8, and an eccentric shaft 9 , handle 10, shockproof pad 11, nut 12, shaft 13, pin shaft 14, slide block 15, first retaining ring 16 and fulcrum 17, one end of motor base 1 is connected with motor 6 casing 3 by fulcrum 17, and The motor base 1 can rotate around the support shaft 17, and the axial position of the support shaft 17 is determined by the first retaining ring 16; the other end of the motor base 1 has a shaft 13 passing through it horizontally, and the axial position of the shaft 13 is determined by the second retaining ring 7 Fixed, the shaft 13 is covered with a slider 15, the slider 15 is fixed on the shaft end edge of the eccentric shaft 9 through the pin shaft 14, the eccentric shaft 9 is fixed on the motor box 3 through the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com