Exhaust gas recirculation cooling water pump structure

A technology of exhaust gas recirculation and cooling water pump, applied in exhaust gas recirculation, pump, pump device and other directions, can solve the problem of unsatisfactory cooling effect of recirculated exhaust gas, achieve the effect of simple structure, meet emission regulations, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

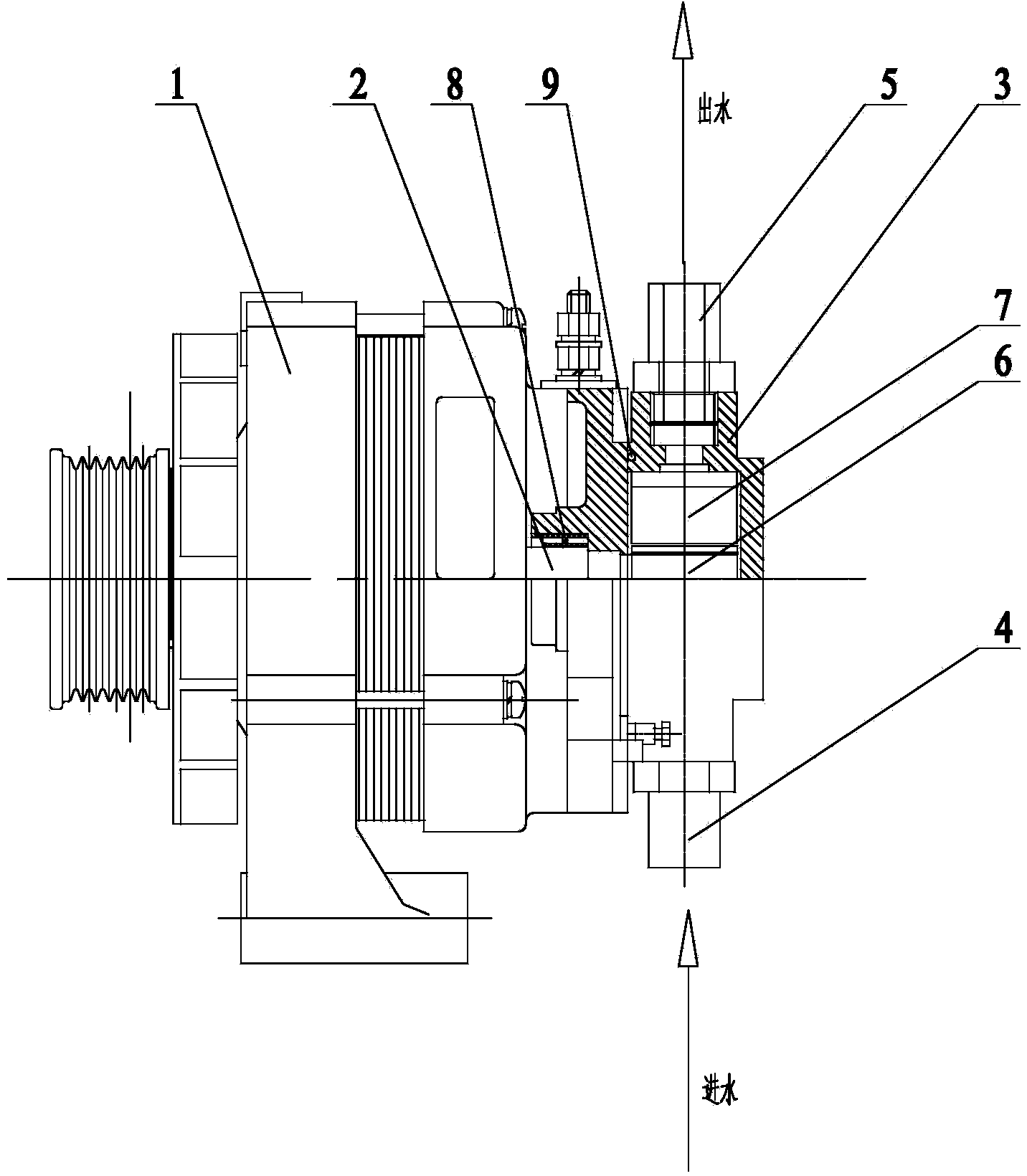

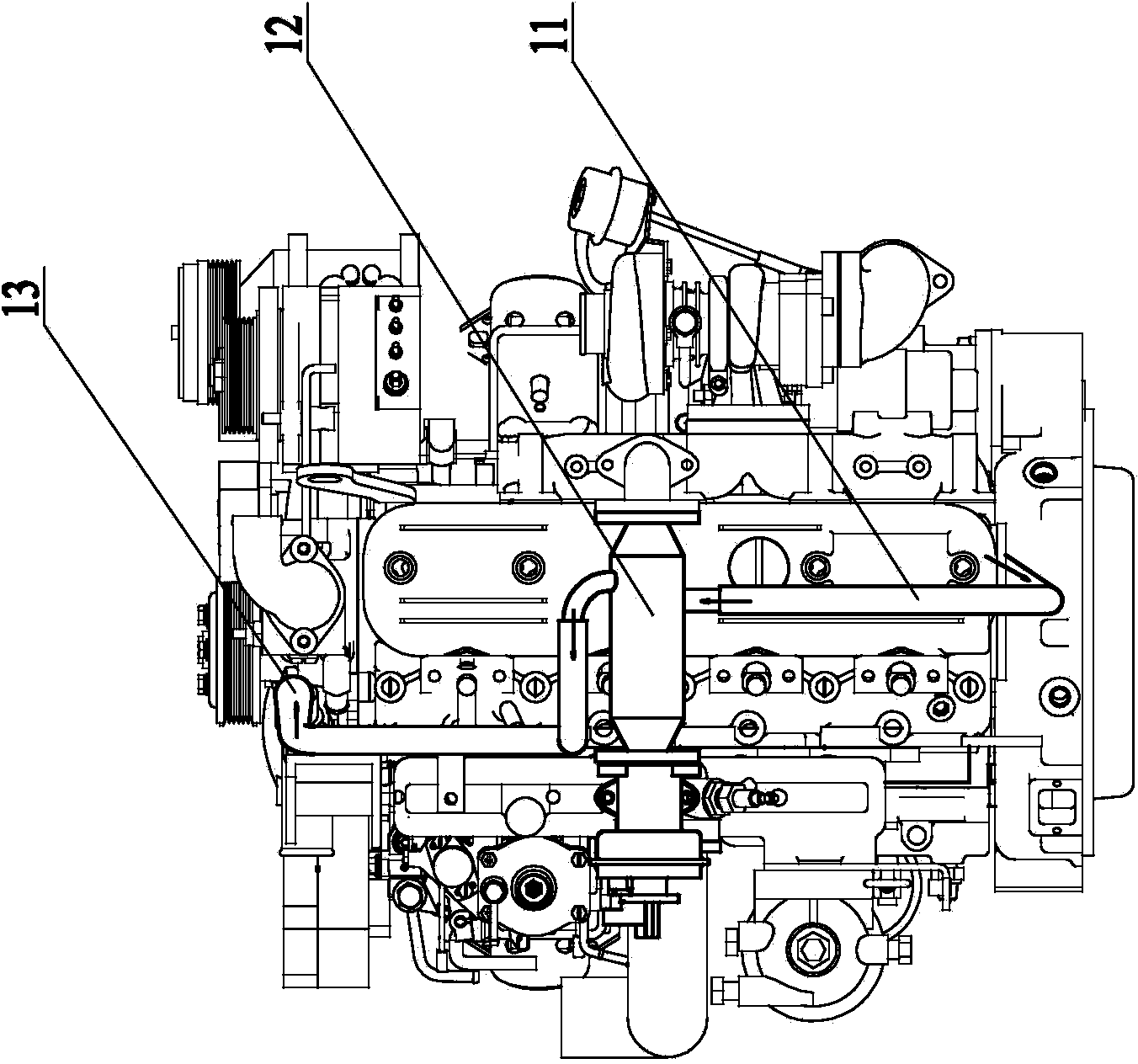

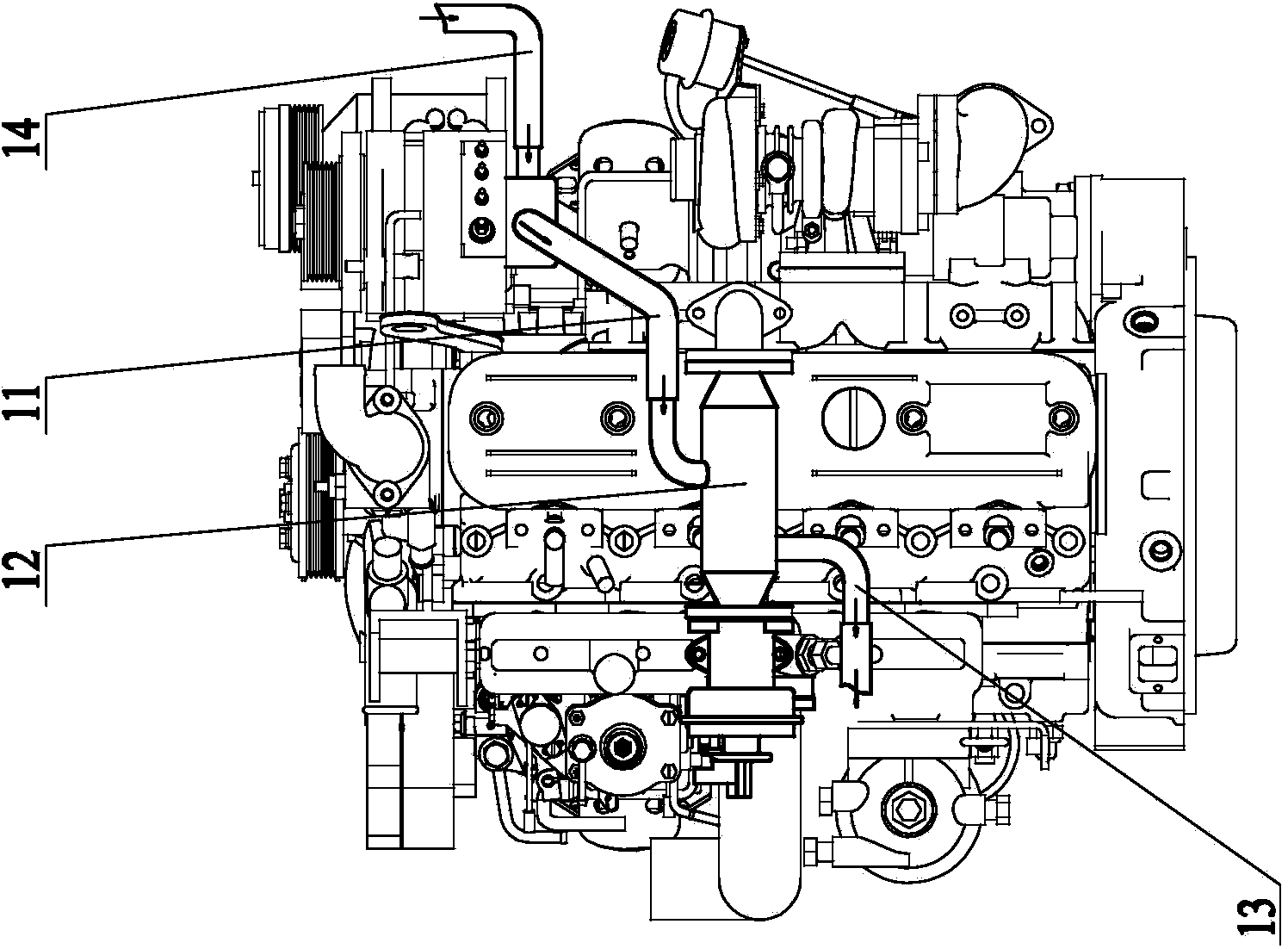

[0013] The exhaust gas recirculation cooling water pump structure includes a diesel engine generator housing 1, a generator shaft 2 is rotatably installed in the diesel engine generator housing 1, and a diesel generator shaft 2 is fixed on the diesel engine generator housing 1 corresponding to the output end of the generator shaft 2. The water pump housing 3 is provided with a water inlet joint 4 and a water outlet joint 5 on the water pump housing 3, and a pump rotor 6 is arranged in the water pump housing 3, and the pump rotor 6 is coaxially fixed with the generator shaft 2, and The pump rotor 6 is provided with vanes 7 .

[0014] A water seal ring 8 is provided between the generator rotating shaft 2 and the housing 1 of the diesel engine generator.

[0015] An O-ring 9 is provided between the water pump housing 3 and the diesel generator housing 1 .

[0016] The present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com