Large-diameter high-pressure-resistant hollow fiber reinforced plastic anchor rod and production process thereof

A fiber-reinforced plastic and production process technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of small inner holes, poor blasting pressure resistance, etc., to improve pressure resistance, improve bonding strength, The effect of saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

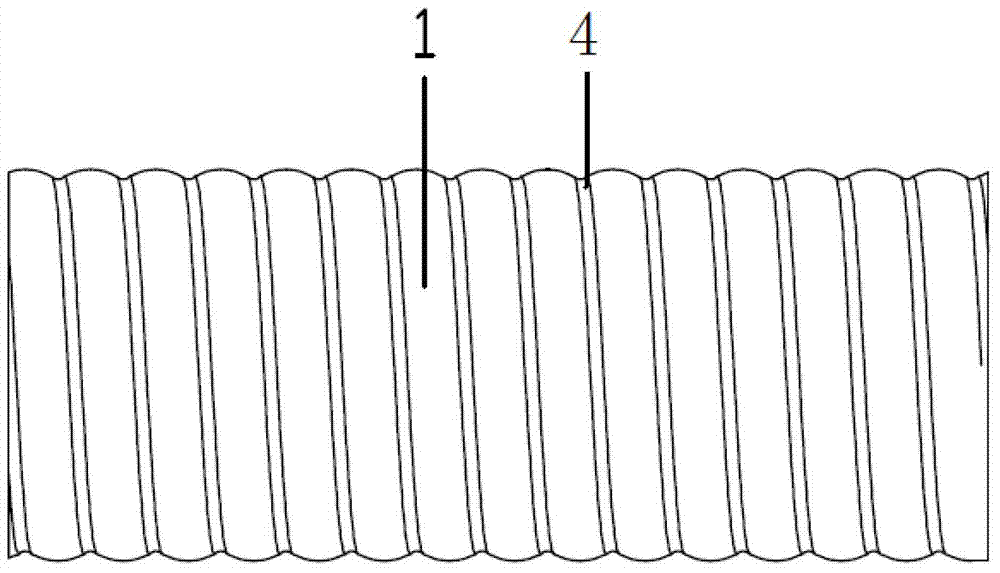

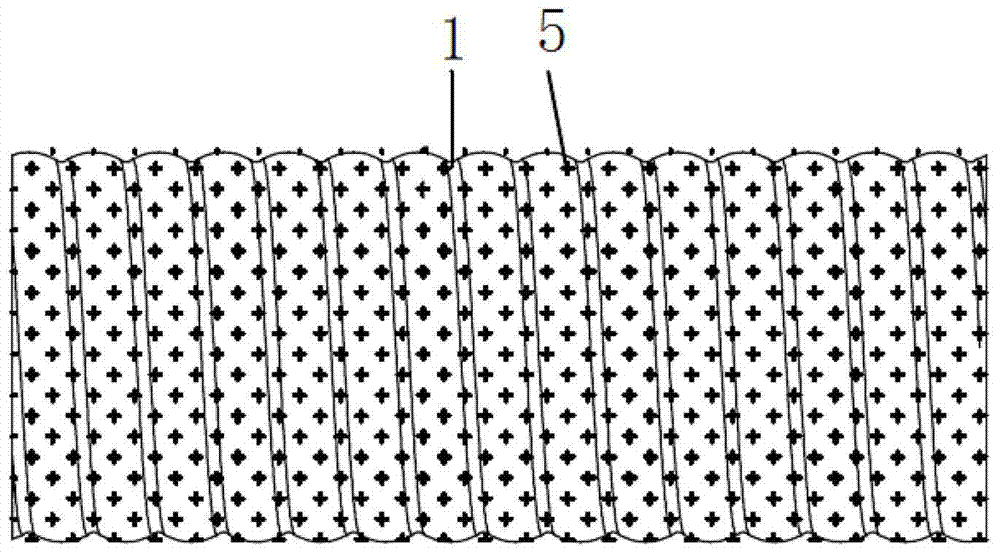

[0032] Embodiment 1, producing a large-diameter high-pressure-resistant hollow fiber-reinforced plastic anchor rod with an outer diameter of 60 mm and an inner hole diameter of 40 mm.

[0033] a. Mix and stir unsaturated polyester resin, dibenzoyl peroxide, aluminum hydroxide and decabromodiphenyl ether to form a resin solution, and let it stand for 15 minutes. The mass ratio of each component in the resin glue solution is: unsaturated Polyester resin 75%, dibenzoyl peroxide 1%, aluminum hydroxide 15%, decabromodiphenyl ether 9%.

[0034] b. If image 3 and 4 As shown, a mandrel mold 6 with a diameter of 40mm is used, and a preforming mold 7 is arranged at one end of the mandrel mold 6, and a plurality of small holes 8 are uniformly distributed along the circumferential direction on the preforming mold 7. Firstly, the first part of the glass fiber yarn is put into the resin tank through the creel to soak the resin, and then it is drawn to the surface of the mandrel mold 6 th...

Embodiment 2

[0037] Embodiment 2, producing a large-diameter high-pressure-resistant hollow fiber-reinforced plastic anchor rod with an outer diameter of 70 mm and an inner hole diameter of 40 mm.

[0038] a. Mix and stir vinyl resin, tert-butyl peroxybenzoate, calcium carbonate and antimony trioxide to form a resin solution, and let it stand for 30 minutes. The mass ratio of each component in the resin glue solution is: vinyl resin 70% , tert-butyl peroxybenzoate 3%, calcium carbonate 20%, antimony trioxide 7%.

[0039] b. If image 3 and 4As shown, a mandrel mold 6 with a diameter of 40 mm is used, and a preforming mold 7 is arranged at one end of the mandrel mold, and a number of small holes 8 are uniformly distributed along the circumferential direction on the preforming mold 7 . Firstly, the first part of the basalt fiber yarn is put into the resin tank through the creel to soak the resin, and then it is drawn to the surface of the mandrel mold 6 through the small hole 8 on the pref...

Embodiment 3

[0042] Embodiment 3, producing a large-diameter high-pressure-resistant hollow fiber-reinforced plastic anchor rod with an outer diameter of 70 mm and an inner hole diameter of 40 mm.

[0043] a. Mix and stir epoxy resin, tert-butyl peroxybenzoate, aluminum hydroxide and antimony trioxide to form a resin solution, and let it stand for 25 minutes. The mass ratio of each component in the resin glue solution is: epoxy resin 73 %, tert-butyl peroxybenzoate 2%, aluminum hydroxide 17%, antimony trioxide 8%.

[0044] B. If image 3 and 4 As shown, a mandrel mold 6 with a diameter of 40 mm is used, and a preforming mold 7 is arranged at one end of the mandrel mold, and a number of small holes 8 are uniformly distributed along the circumferential direction on the preforming mold 7 . Firstly, the first part of the basalt fiber yarn is put into the resin tank through the creel to soak the resin, and then it is drawn to the surface of the mandrel mold 6 through the small hole 8 on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com