Double-layer water-stopping steel ring for shield starting tunnel portal and mounting method of double-layer water-stopping steel ring

A starting hole and steel ring technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as high construction safety risks and leakage of single-layer water-stop steel rings, and achieve a simple structure and guarantee construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

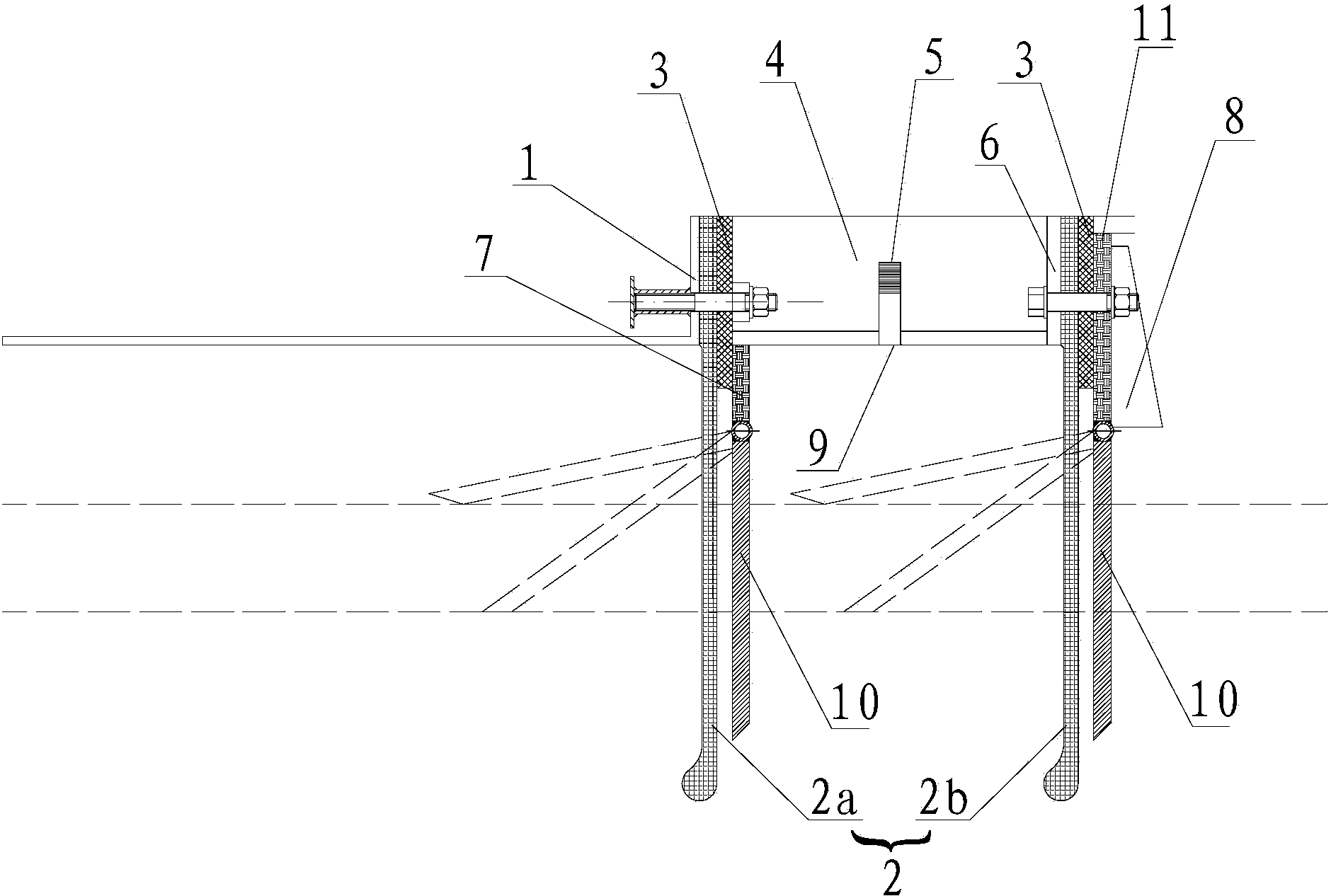

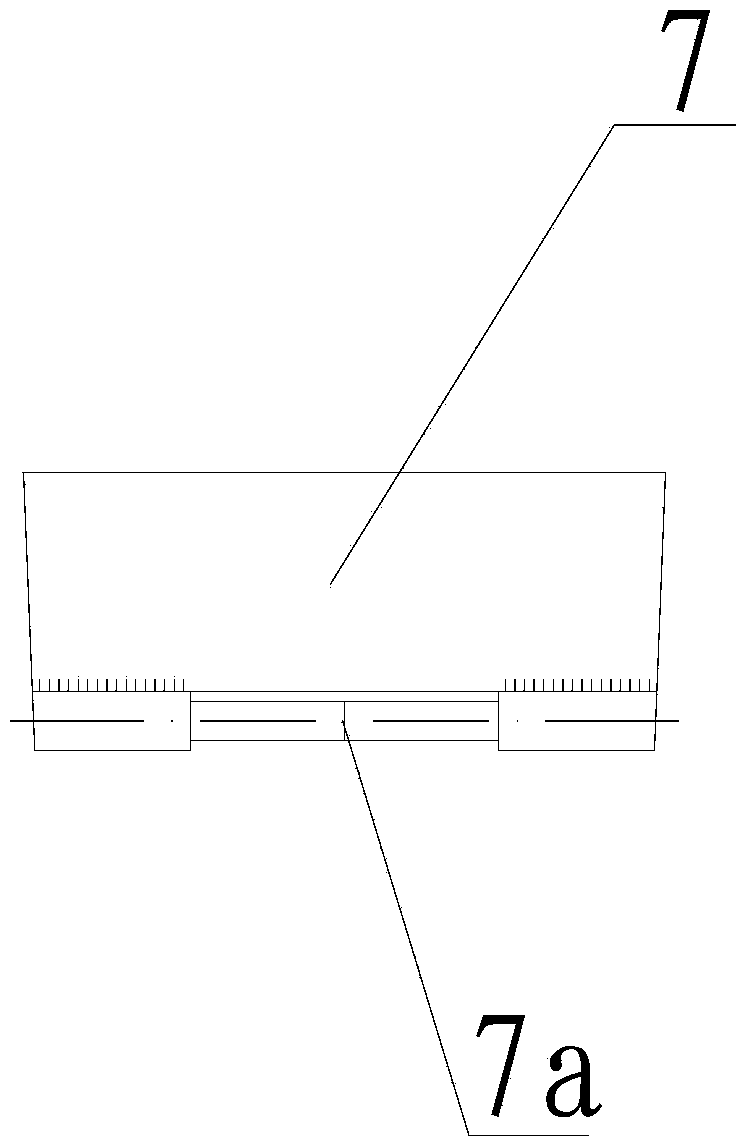

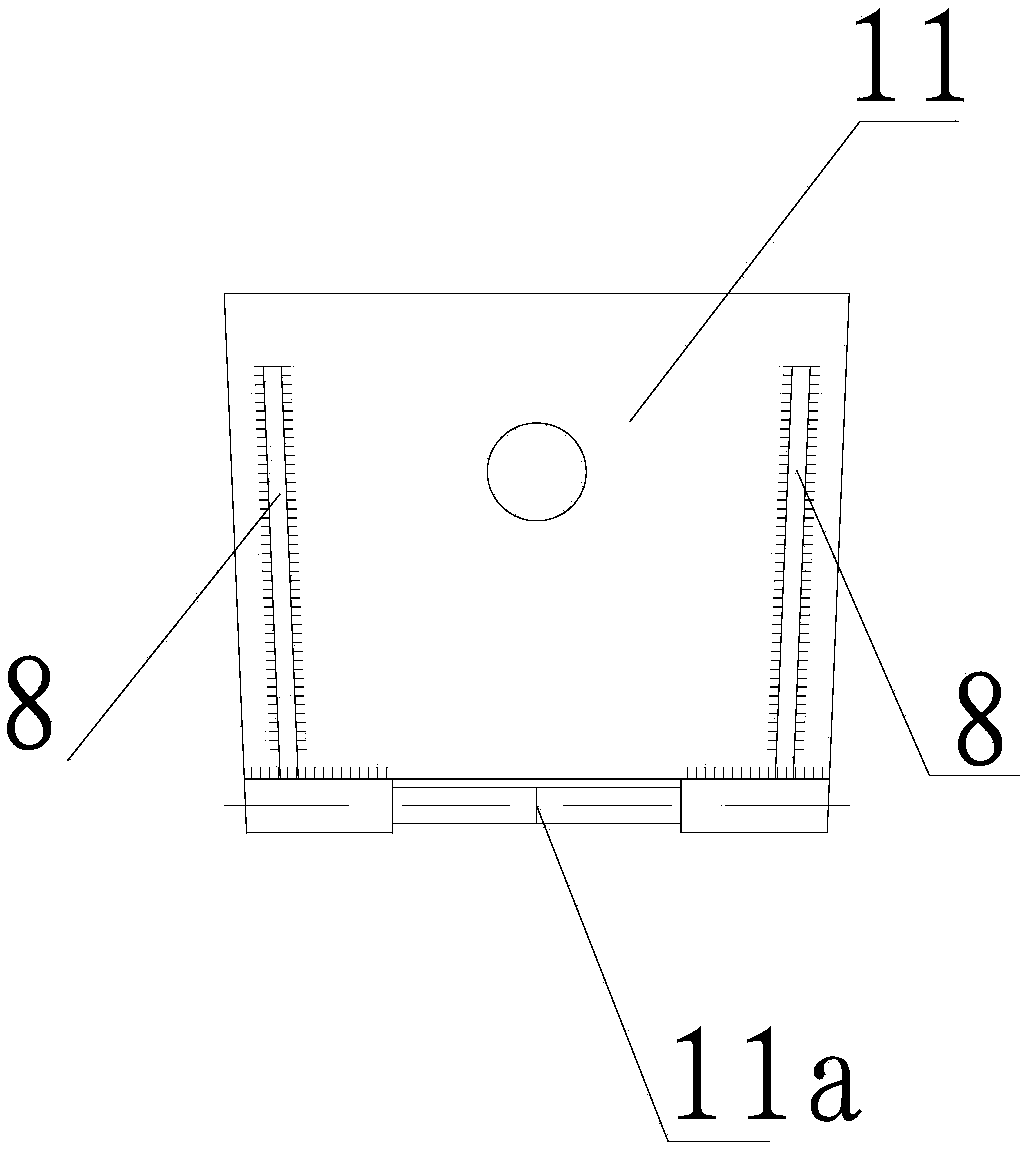

[0029] Such as Figure 1 to Figure 4 Shown: The double-layer water-stop steel ring of the starting hole of the shield machine is composed of a pre-embedded steel ring 1, a cord rubber plate 2, a fixed ring plate 3, a rib plate 4, a grouting pipe 5, a front plate 6, and the first ring plate 7. A stiffening plate 8, a water-stop box 9, a flap 10 and a second ring plate 11 are formed. The water-stop box 9 is welded by the fixed ring plate 3 , the grouting pipe 5 and the front plate 6 , and the rib plate 4 is installed in the water-stop box 9 . The thickness of the fixed ring plate 3 is 16 mm, the thickness of the front plate 6 is 16 mm, the size of the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com