Novel push-and-pull sealing structure

A sealing structure and a new technology, applied in the direction of sealing devices, etc., can solve the problems of easy air leakage and water seepage, short service life, poor sealing performance, etc., and achieve excellent weather resistance and other performance, long service life and tight sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

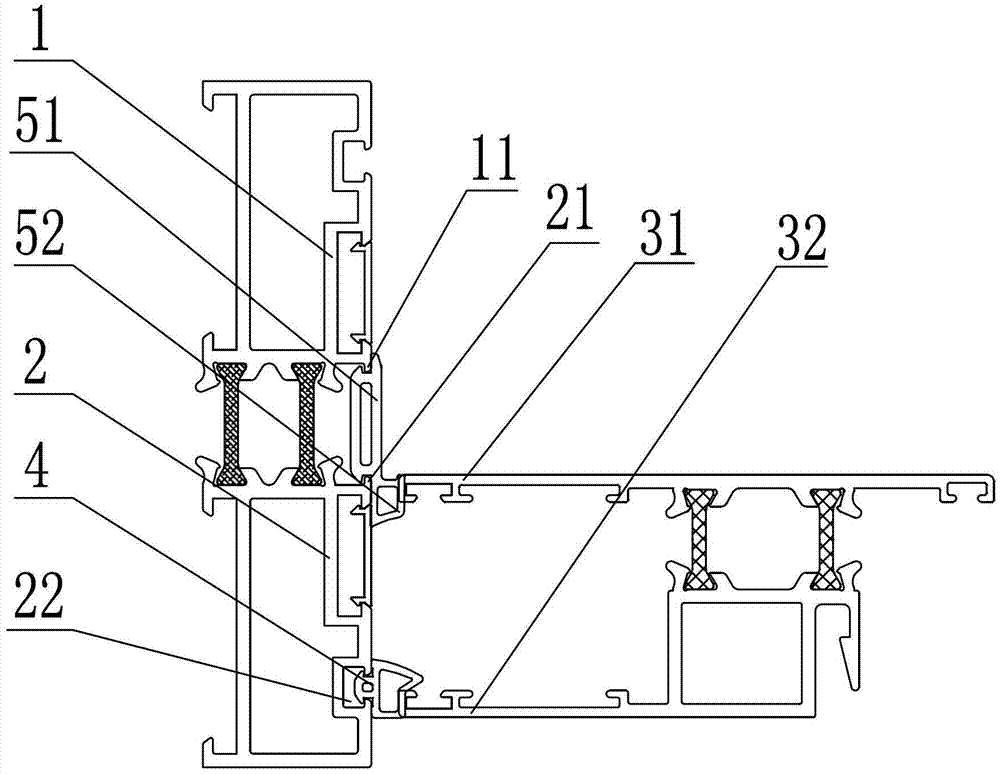

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

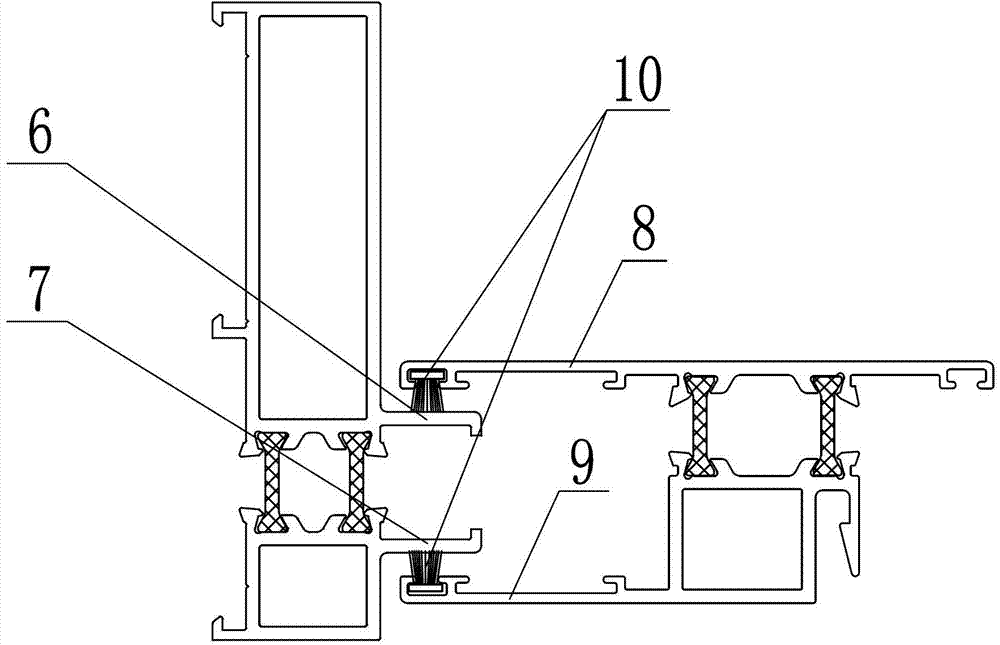

[0012] Such as figure 2 A new type of push-pull sealing structure is shown, including indoor side frame material 1, outdoor side frame material 2, indoor side fan material, outdoor side fan material, frame sealing strip 4 and middle sealing strip, indoor side frame material 1 and chamber The outer frame material 2 is connected by a broken bridge heat insulation connector, and the indoor side fan material and the outdoor side fan material are also connected by a broken bridge heat insulation connector. The connection surface of the indoor side frame material 1 and the outdoor side frame material 2 is close to the fan material A first protrusion 11 is provided on one side, and a second protrusion 21 is provided at a position corresponding to the first protrusion 11 on the outdoor side frame material 2; The sealing part 52, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com