Rivet plate for construction installation and construction installation structure

An installation structure and installation technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of sagging connection hole gaps, potential safety hazards of de-welding, loosening of anchors, etc., to increase connection strength and improve installation safety. performance, meet the seismic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

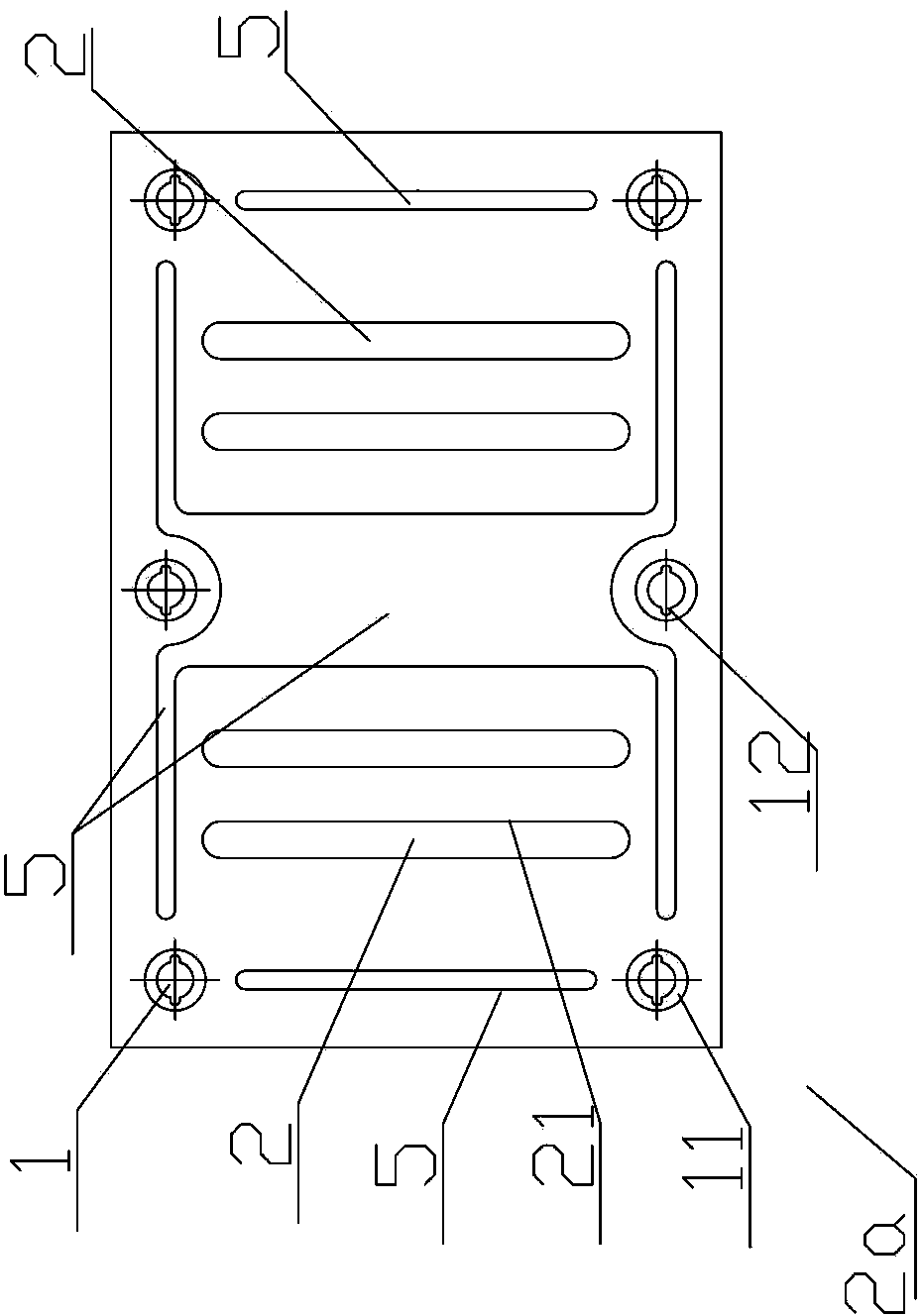

[0040] Such as figure 1 , 1a In the curtain wall installation system shown, the labels of each component are: 1a, concrete foundation, 2a, riveted plate connected with the concrete foundation, A, secondary connector of the present invention, 3a, hollow column, 4a, beam, 5a, Hook receiving seat, 6a, hook, 7a, curtain wall panel.

[0041]The rivet plate 2a for building installation provided by the present invention includes a first connection hole 1 for the installation of the rivet plate 2a itself and a second connection hole 2 for installation as a secondary connector A; the second connection hole 2 is a long hole; the riveted plate 2a has a sinking area 5 for being buried in the concrete foundation, the second connection hole 2 is not in the sinking area 5, and passes through the sinking area so that The back of the rivet plate forms a space 50 around the opening of the second connection hole to fit the metal rivet head of the rivet bolt; Form clamping connection outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com