Screen printing ink

A technology of screen printing ink and polyester resin, applied in the direction of ink, household utensils, application, etc., can solve the problem of restricting the use of ink, and achieve the effect of improving the yield rate, reducing cost and high shielding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

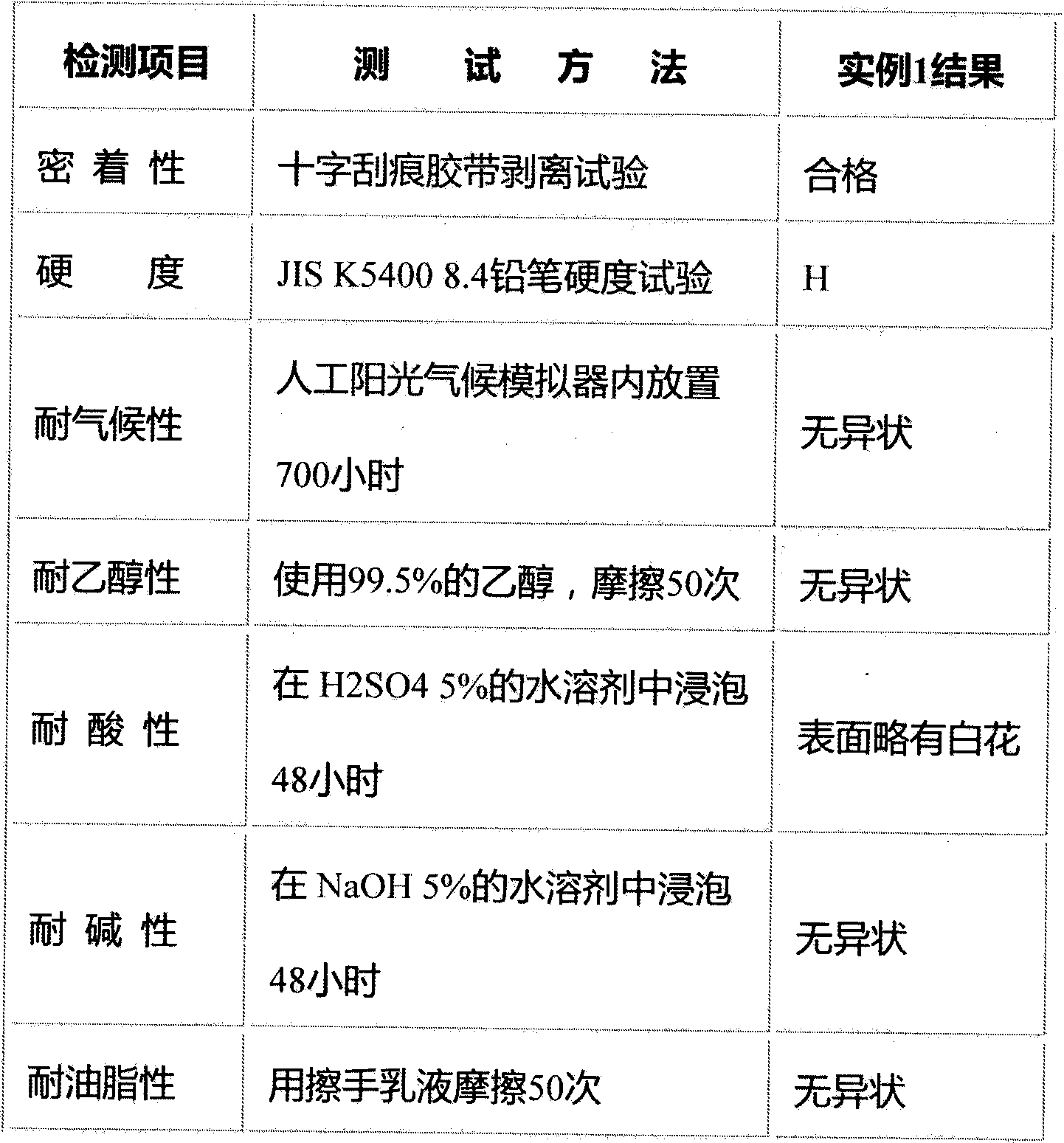

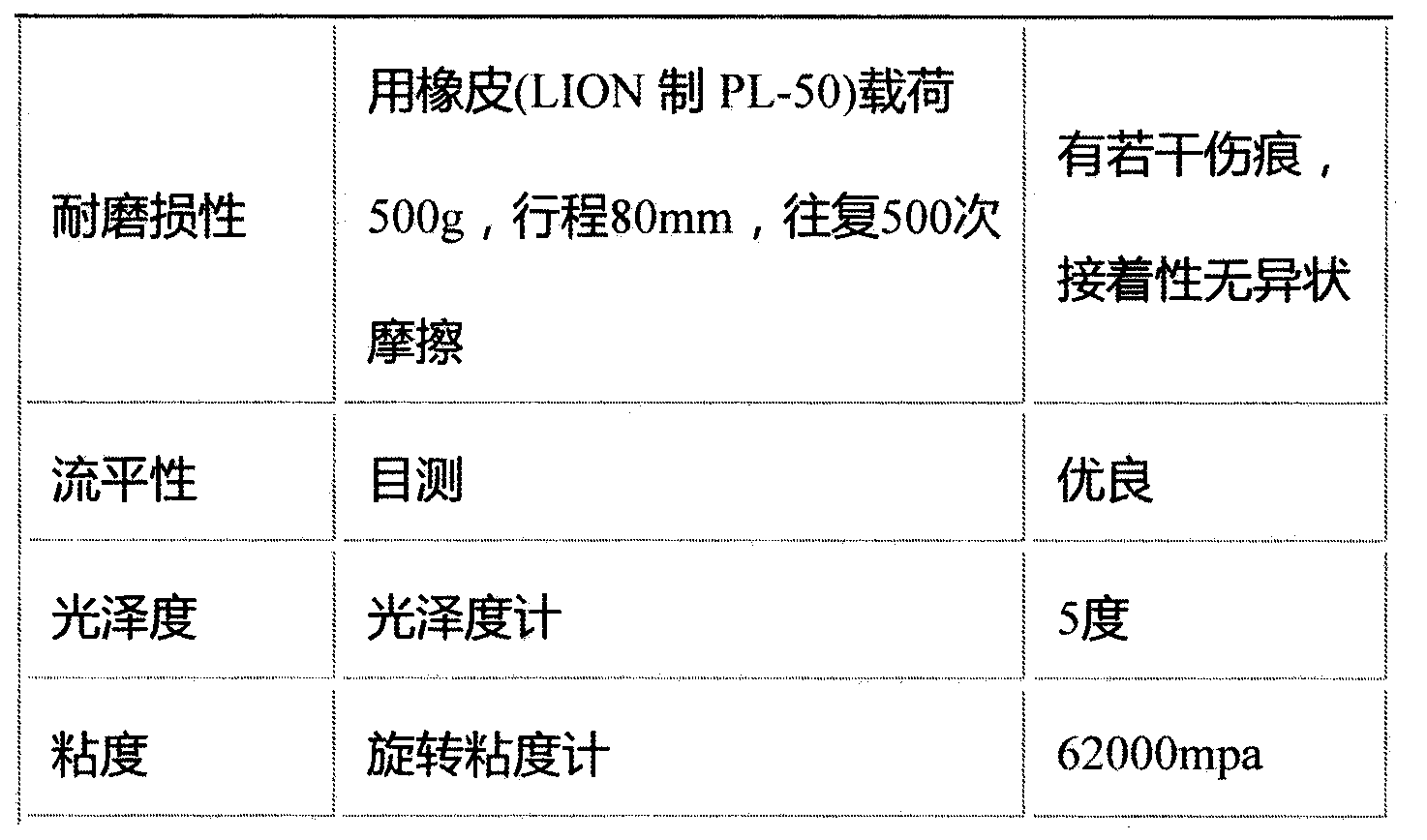

Embodiment 1

[0023] Take 60wt% polyester resin, add 1wt% additive, mix evenly, then add 9wt% carbon black and 30wt% filler, and stir for 10 minutes. After stirring evenly, grind on a three-roller machine to make the particle size of the solid particles smaller and uniform. Finally, filter with gauze, the gauze is 200 mesh. After drying, the finished screen printing ink is obtained.

Embodiment 2

[0025] Take 50wt% polyester resin, add 0.8wt% additives, mix evenly, then add 6wt% carbon black and 35wt% filler, and stir for 10 minutes. After stirring evenly, grind on a three-roller machine to make the particle size of the solid particles smaller and uniform. Finally, filter with gauze, the gauze is 200 mesh. After drying, the finished screen printing ink is obtained.

Embodiment 3

[0027] Take 70wt% polyester resin, add 1.6wt% additives, mix well, then add 10wt% carbon black and 40wt% filler, and stir for 15min. After stirring evenly, grind on a three-roller machine to make the particle size of the solid particles smaller and uniform. Finally, filter with gauze, the gauze is 200 mesh. After drying, the finished screen printing ink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com