Preparation method of N-acylamino acid or salt thereof

An acyl amino acid and amino acid technology are applied in the field of preparation of N-acyl amino acid surfactants, which can solve the problems of uneven mixing of the reaction system, poor reaction uniformity, and difficulty in continuous production, and achieve compact structure, small footprint, Simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

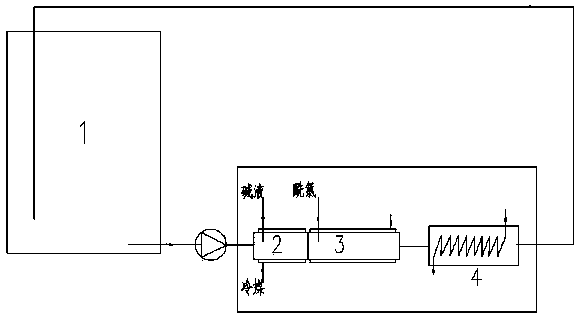

[0040] Batch preparation method of sodium cocoyl glycinate

[0041] The 2500Kg sodium glycinate aqueous solution from the storage tank (sodium glycinate content of 10wt%, pH value of 9.0, temperature of 20℃) and 30% sodium hydroxide solution with gear pump (applicable viscosity of 30Pa.s) were respectively 15M 3 / h and 0-0.5M 3 The / h flow rate is pumped into Sulzer's SMX-type first-stage static mixer, and the cocoyl chloride 500Kg, with 0.50M 3 The / h flow is pumped into the secondary static mixer with an acid-resistant pump, the shells of the primary and secondary static mixers are cooled with refrigerant, the temperature of the material at the outlet of the secondary static mixer is maintained at 20-30 °C, and the pH value is maintained at 9-10. The pH value is adjusted by adjusting the flow rate of sodium hydroxide solution, the material flows through the cooler to cool down to 20°C, returns to the glycine storage tank, and performs a cyclic reaction. The dropwise additio...

Embodiment 2

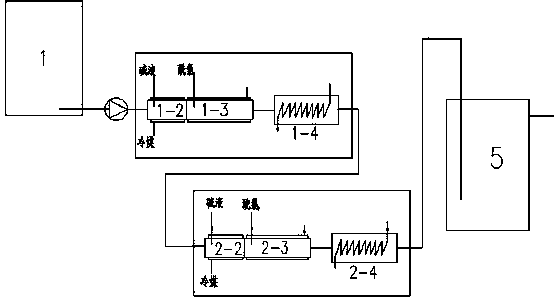

[0049] Continuous preparation of sodium cocoyl glycinate

[0050] 8% sodium glycinate aqueous solution, 25% sodium hydroxide solution, and cocoyl chloride respectively enter the first mixing reaction unit composed of two-stage SMX static mixer and cooler according to the flow ratio of 5:0.35:0.4 (weight), and the static mixing The device is cooled by refrigerant. Mixed material and 25% sodium hydroxide solution, cocoyl chloride respectively according to flow ratio 5.7:0.3:0.4 (weight) then enter the second mixing reaction unit, this unit is also made up of two-stage SMX static mixer and cooler. The temperature of the material entering the first mixing reaction unit is 15-20°C. As the reaction proceeds gradually, the heat released is taken away by the cooling medium. The outlet temperature of the cooler of the second mixing reaction unit is controlled at 25-35°C, and the pH is adjusted by adjusting The sodium hydroxide flow is controlled at 8-10. After the material is fully m...

Embodiment 3

[0052] Batch preparation method of sodium C12 acyl glycinate

[0053] Using the same conditions as in Example 1, C12 acid chloride was used to replace cocoyl chloride and the molar ratio of glycine was kept at 1:1, and KOH was used to replace sodium hydroxide. The detection result of the reactant was 0.7% potassium glycinate, the conversion rate was 90%, and the material viscosity was 3600 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com