Method of bitumen solidification for waste incineration slag aggregate

A technology for solidifying waste incineration slag and asphalt, which is applied in the field of resource utilization of solid waste, can solve the problems of low solidification effect of soluble salt, high cost, and difficulty in resource utilization of waste incineration slag, and achieves improved anti-rutting performance. , The effect of improving water damage resistance and excellent road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

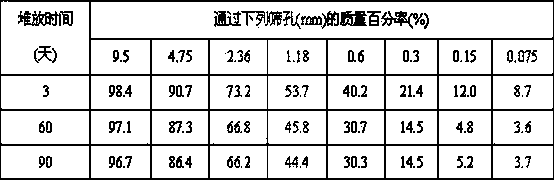

[0019] In this example, the performance of the waste incinerator slag aggregate is tested. The crushing value and water absorption are shown in Table 1. The particle size distribution is shown in Table 2. As the mechanical properties of waste incineration slag aggregate increase with the stacking time, the mechanical properties of slag-asphalt mixture can be improved; with the stacking time, the water absorption rate of waste incineration slag aggregate decreases, and the adsorption of asphalt in slag-asphalt mixture decreases, which can reduce the mixing rate. It is beneficial to reduce the cost of the mixture by reducing the amount of asphalt in the material; with the stacking time, the slag aggregate particles will expand, resulting in a change in gradation. In order to ensure the performance of the slag-asphalt mixture, the slag aggregate needs to be stacked for a period of time before it is solidified with asphalt, and it is recommended to stack for more than 90 days fro...

Embodiment 2

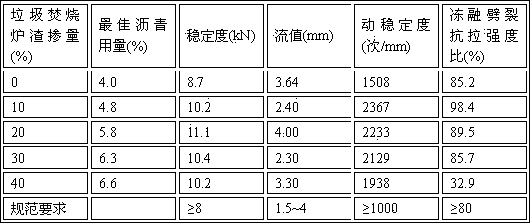

[0026] In this example, the road performance of the waste incineration slag asphalt mixture is tested. Basalt aggregate with a maximum particle size of 19.5mm, ordinary 70# matrix asphalt and ordinary limestone filler are used. The mass ratios of waste incineration slag aggregates replacing basalt aggregates are 0, 10%, 20%, 30% and 40%, respectively. The method of solidifying asphalt waste incineration slag aggregate: it is composed of the following components in weight percentage: waste incineration slag aggregate 0~40%, stone 55~80%, mineral powder 4%~9% and asphalt, at 165 ℃ Stir for 90 seconds. According to the industry standard "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40-2004), the Marshall test method for asphalt mixture was used to determine the optimal amount of asphalt. The performance of the mixture is shown in Table 3.

[0027] Table 3 Performance parameters of asphalt mixture

[0028]

[0029] In summary, this example shows ...

Embodiment 3

[0031] In this example, the environmental impact of the slag asphalt mixture was tested from two aspects: the leaching amount of soluble salts and the acute biological toxicity.

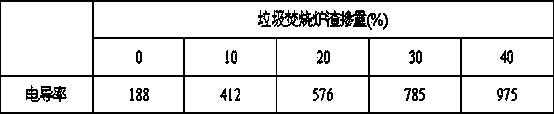

[0032] The leaching amount of chloride salt of slag-asphalt mixture is 12-31g / L, the leaching amount of sulfate is 9-17g / L, and the leaching amount of soluble salt is significantly smaller than that of waste incineration slag. The electrical conductivity of the leaching solution of the slag aggregate is 9430 μS / cm; the electrical conductivity of the leaching solution of the slag-asphalt mixture is shown in Table 4. The electrical conductivity (<1000μS / cm) of the slag-asphalt mixture leaching solution is much smaller than that of the slag leaching solution, which indicates that asphalt has a stable and solidifying effect on pollutants in waste incineration slag aggregates, which can be explained from two aspects: asphalt is a hydrophobic substance , blocks the pores in the waste incinerator slag aggre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com