Method for preparing activated carbon from camellia seed waste residues

A technology for preparing activated carbon and camellia oleifera seed, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of limited use range of activated carbon prices, and achieve high product performance-price ratio, excellent adsorption performance, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

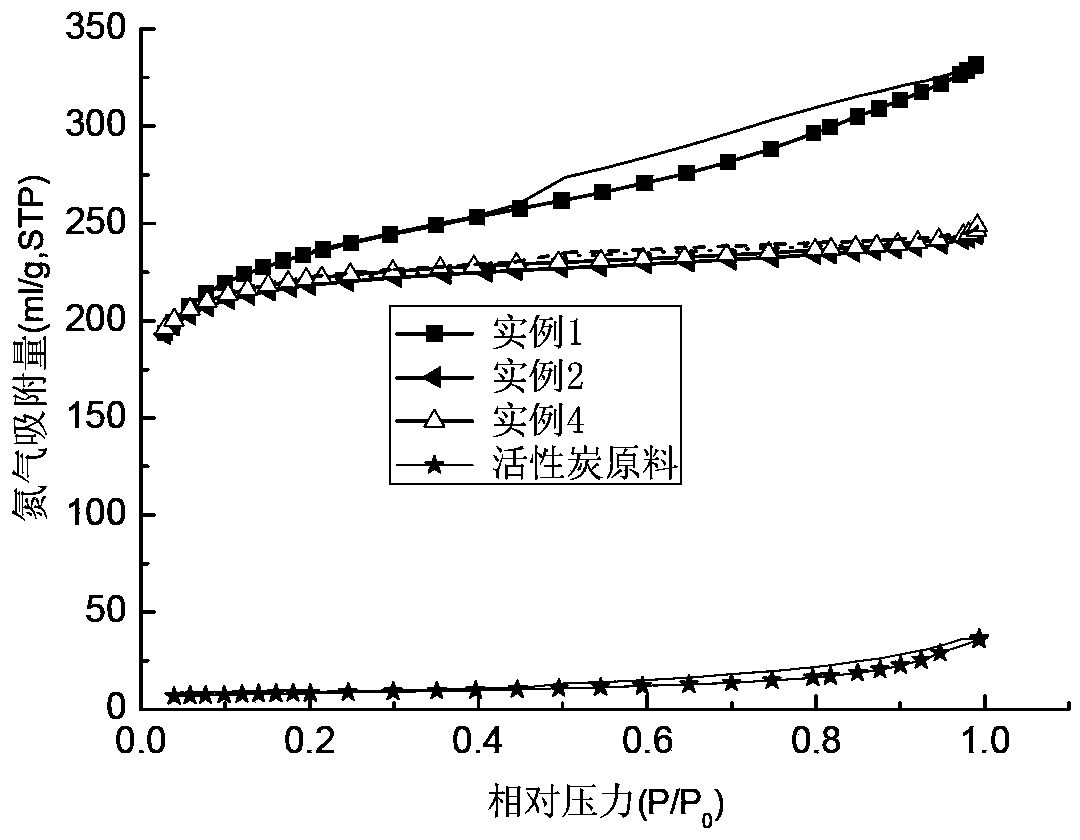

Embodiment 1

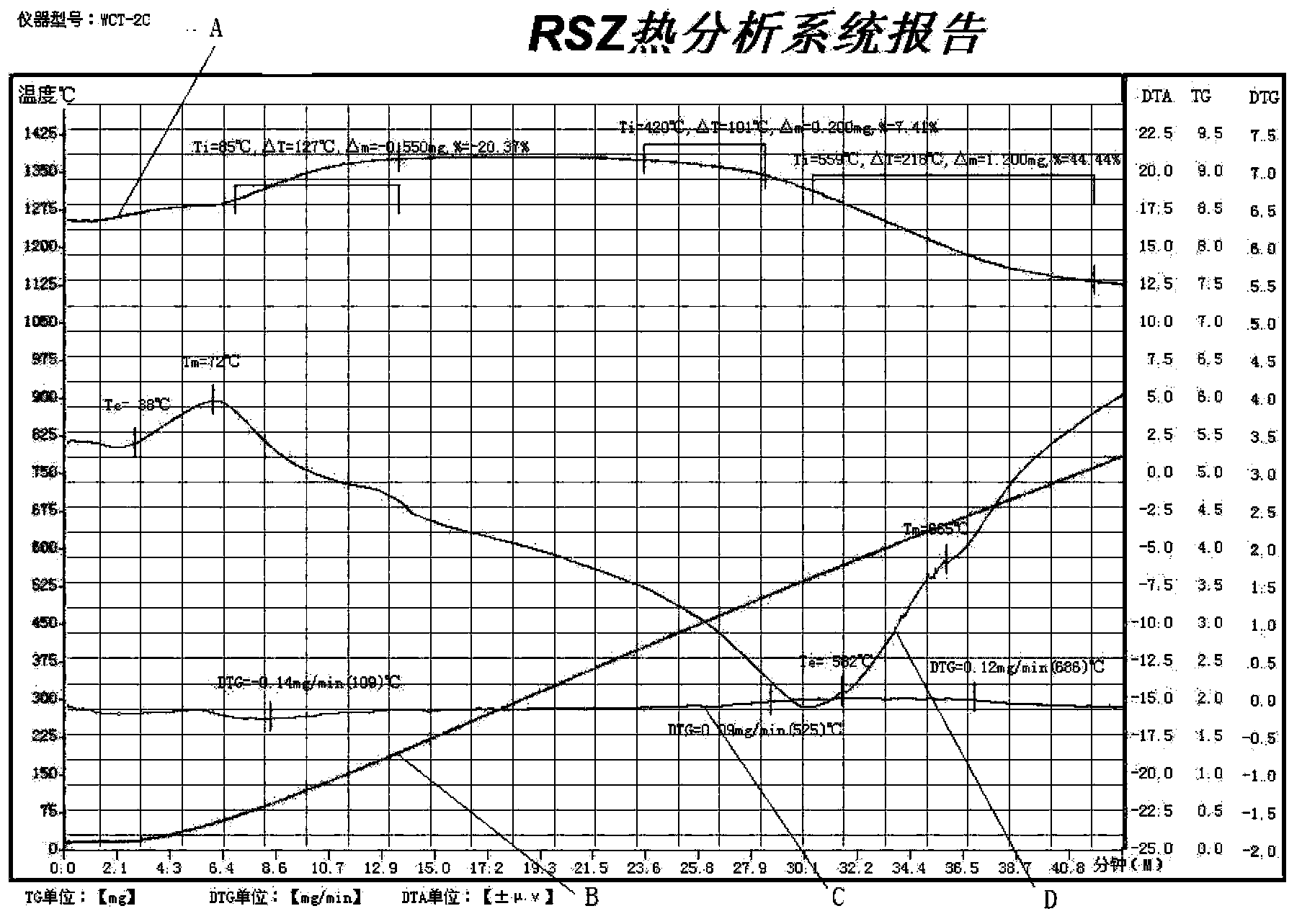

[0028] Pulverizing and sieving camellia seed waste residue obtained from various camellia seed oil extraction plants to obtain camellia seed waste residue particles with a particle size of 0.125-2 mm, preferably 1 mm;

[0029] The camellia seed waste residue particles are heated to 550°C for 60 minutes at a heating rate of 10-20°C / min, preferably 12°C / min, for 60 minutes under an inert atmosphere, and cooled to room temperature to obtain a carbonized material of camellia seed waste residue;

[0030] According to the weight ratio of 1:1.5~3.5, preferably 1:2.5, impregnate the carbonized material of camellia seed waste residue obtained in the previous step in a potassium carbonate solution with a mass percentage concentration of 50%, stir evenly during the impregnation process, and impregnate at room temperature for 24 hours. Carry out dehydration treatment, and dry at 105 ℃ for 18 hours to form a mixture;

[0031] The prepared mixture is placed in a carbonization furnace, activ...

Embodiment 2

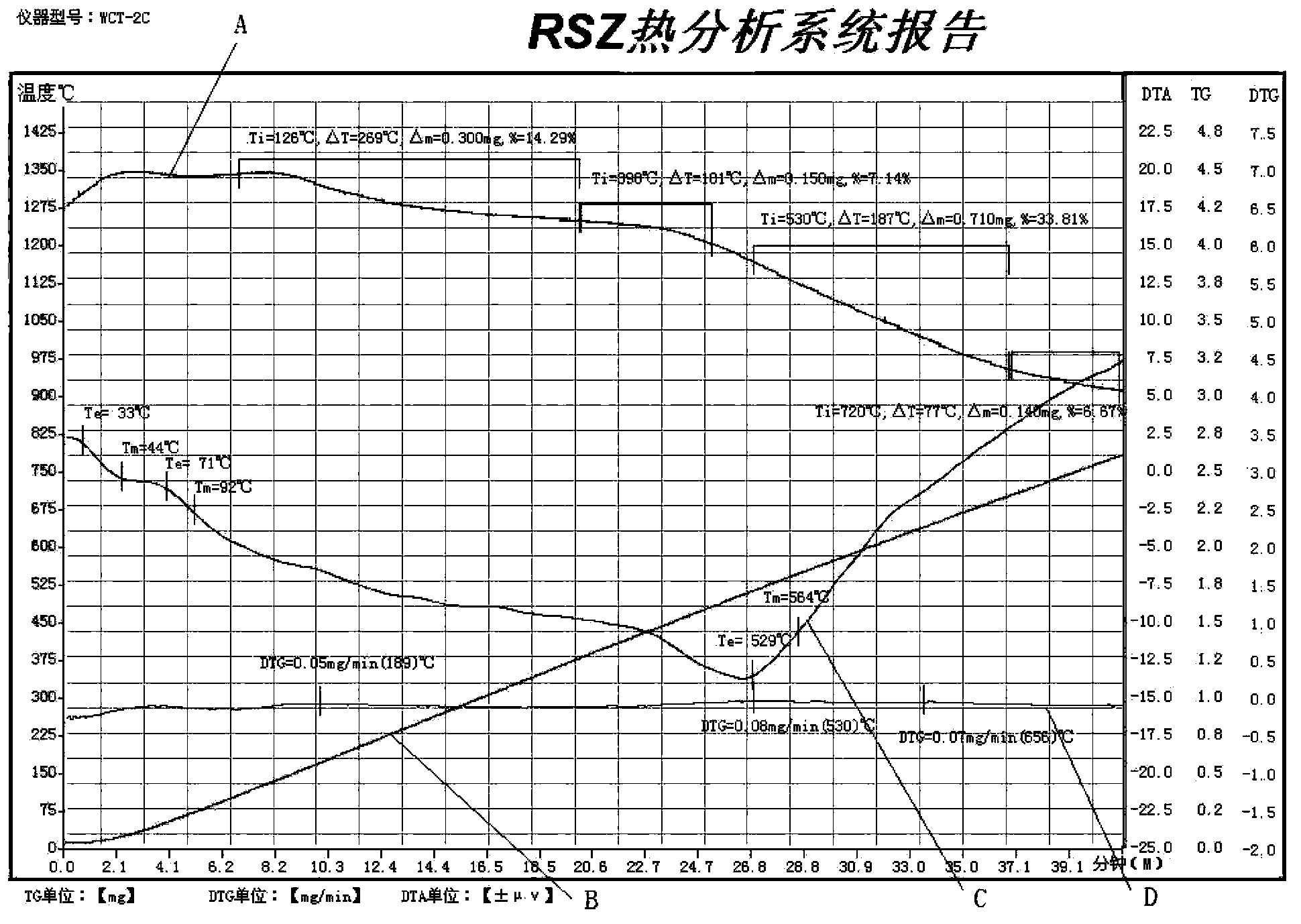

[0035] Pulverizing and sieving camellia seed waste residue obtained from various camellia seed oil extraction plants to obtain camellia seed waste residue particles with a particle size of 0.2-3 mm, preferably 2 mm;

[0036] Heat the camellia seed waste residue particles to 700°C for 30 minutes at a heating rate of 15-25°C / min, preferably 18°C / min, and perform pyrolysis for 30 minutes in an inert atmosphere, and cool to room temperature to obtain a carbonized material of camellia seed waste residue;

[0037] According to the weight ratio of 1:1.5~2.5, preferably 1:1.5, impregnate the carbonized material of camellia seed waste residue obtained in the previous step in a potassium carbonate solution with a mass percentage concentration of 30%, stir evenly during the impregnation process, and impregnate at room temperature for 20 hours. Carry out dehydration treatment and dry at 102°C for 16 hours to form a mixture;

[0038] The prepared mixture is placed in a carbonization furnac...

Embodiment 3

[0042] Pulverizing and sieving camellia seed waste residue obtained from various camellia seed oil extraction plants to obtain camellia seed waste residue particles with a particle size of 0.05-1.5 mm, preferably 1.2 mm;

[0043] Heat the camellia seed waste residue particles to 650°C for 60 minutes at a heating rate of 5-15°C / min, preferably 12°C / min, and perform pyrolysis for 60 minutes in an inert atmosphere, and cool to room temperature to obtain a carbonized material of camellia seed waste residue;

[0044] According to the weight ratio of 1:1.5~2, preferably 1:1.5, impregnate the carbonized material of camellia seed waste residue obtained in the previous step in a potassium carbonate solution with a mass percentage concentration of 50%, stir evenly during the impregnation process, and impregnate at room temperature for 24 hours. Carry out dehydration treatment, and dry at 108 ℃ for 18 hours to form a mixture;

[0045]The prepared mixture is placed in a carbonization furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com