Steel tube bundling device

A technology of steel pipe and support frame, applied in the field of frame body, can solve problems such as hidden safety hazards and increase stacking space, and achieve the effects of eliminating hidden safety hazards, improving work efficiency and increasing storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

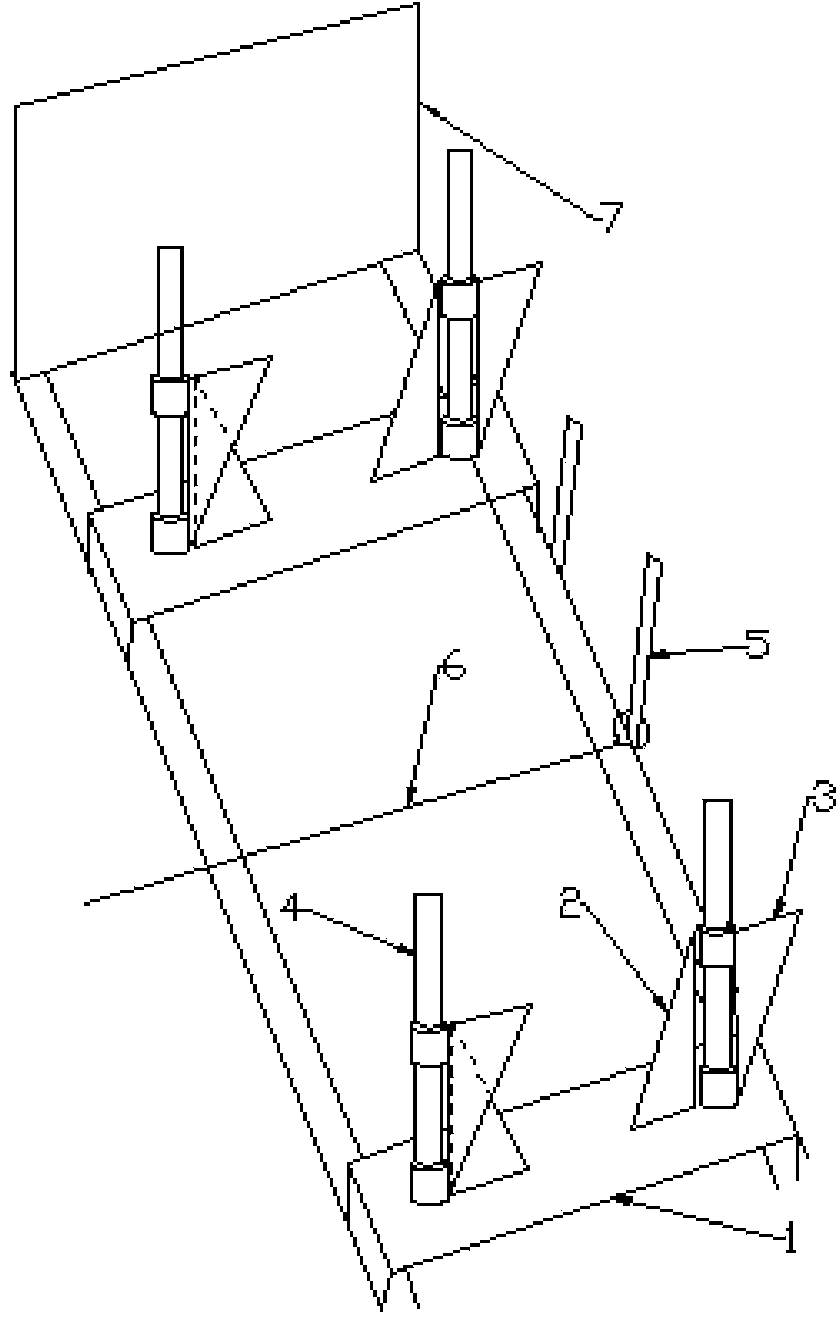

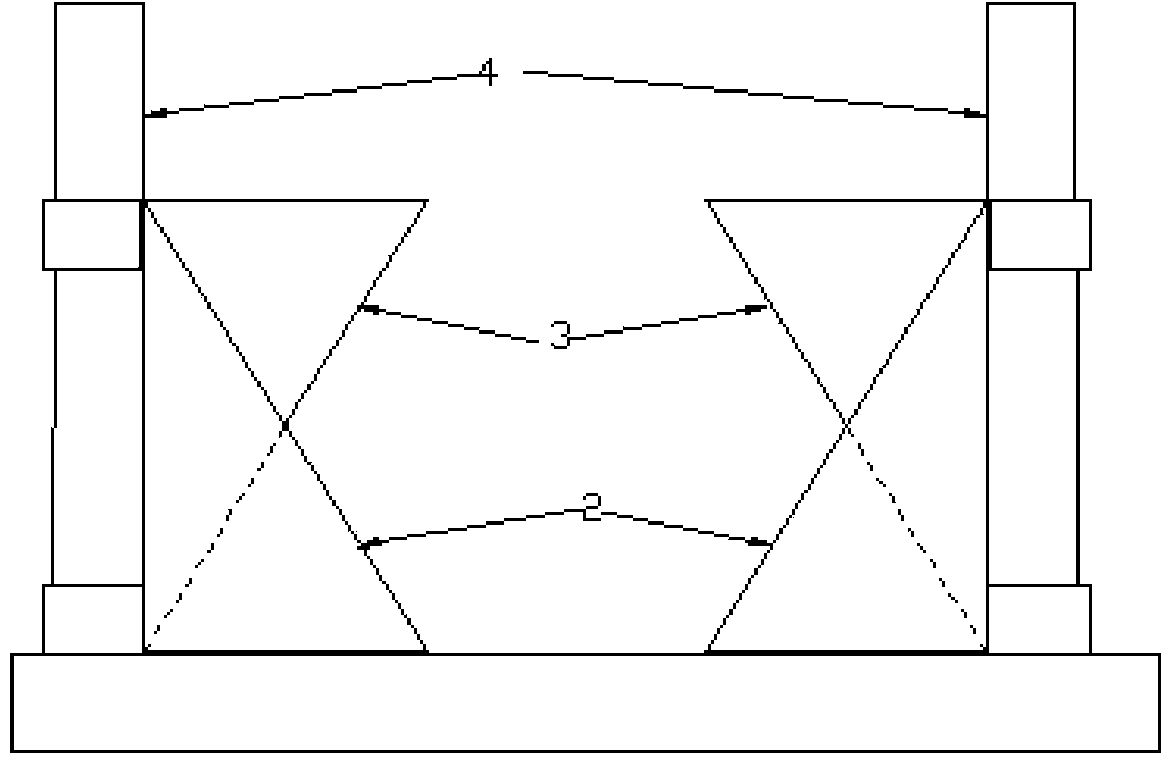

[0012] see figure 1 and figure 2 , the packing device for steel pipes of the present invention comprises a base 1, a first packing support frame 2 of four right-angled triangles, four fixing rods 4 and a second packing supporting frame 3 of four right-angled triangles, and the fixing rods 4 are in groups of two It is fixed at both ends of the base 1 and distributed in a square shape. One right-angled side of the four second packing support frames 3 is respectively movably connected with a fixed rod 4, and can freely rotate around the fixed rod 4. The other right-angled side is located at Above the right-angled side; the first packing support frame 2 is also fixed on the base 1 in groups of two, and is also distributed in a square shape. Each of the four first packing support frames 2 has a right-angled side fixed to the base 1, and the same group The fixed right-angled sides of the two first packing support frames 2 are parallel to each other or on the same straight line, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com