Automatic assembly line capable of continuously assembling automobile guy cable casing fittings

A cable casing and assembly line technology, which is applied in the field of automatic assembly production lines, can solve problems such as unguaranteed product quality, low production efficiency, and wrong installation of shock absorbing pads, so as to reduce personnel, reduce labor intensity, and avoid Effects of wrong and missing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to help examiners better understand the present invention, the present invention will be further described in detail below according to the accompanying drawings:

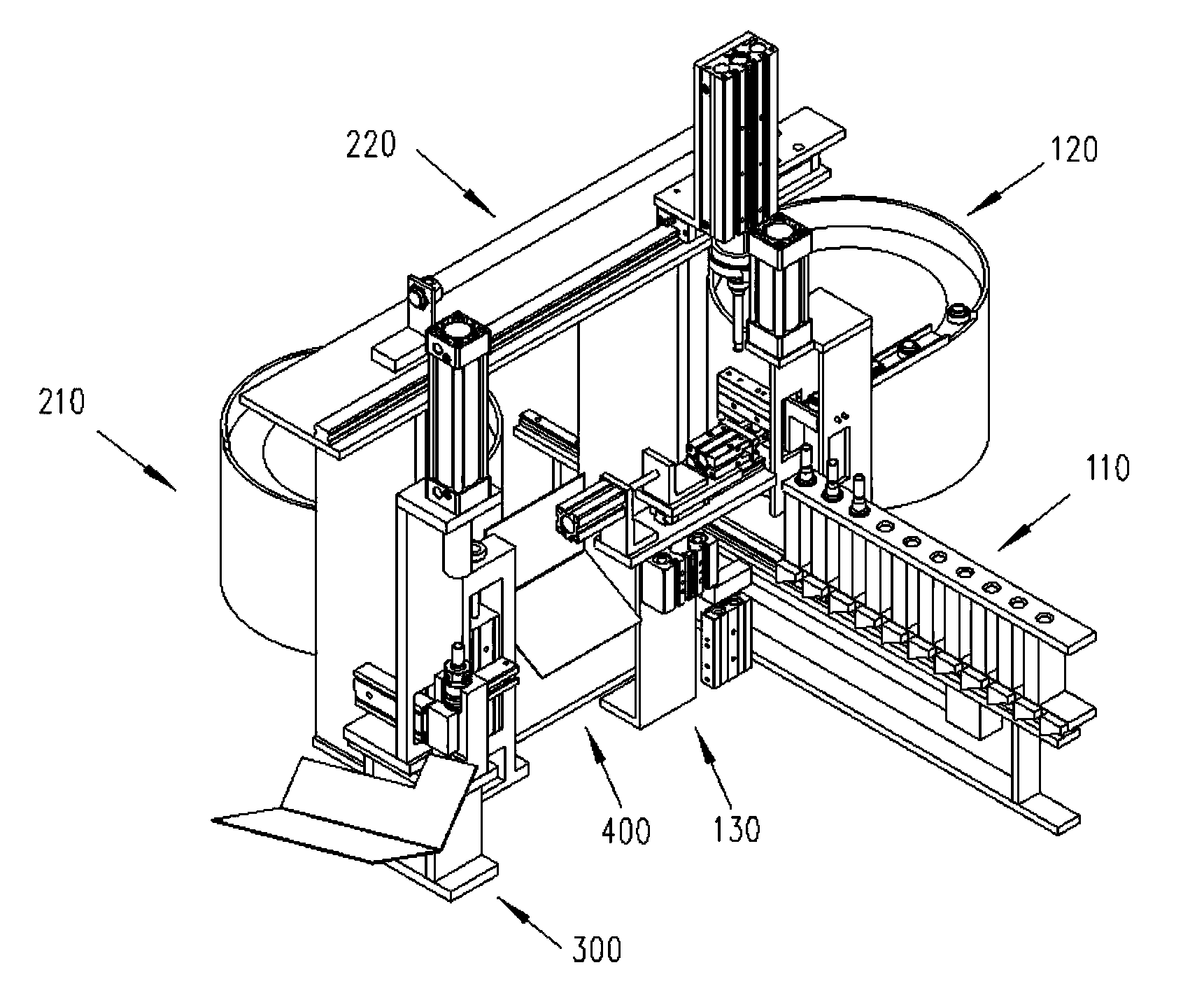

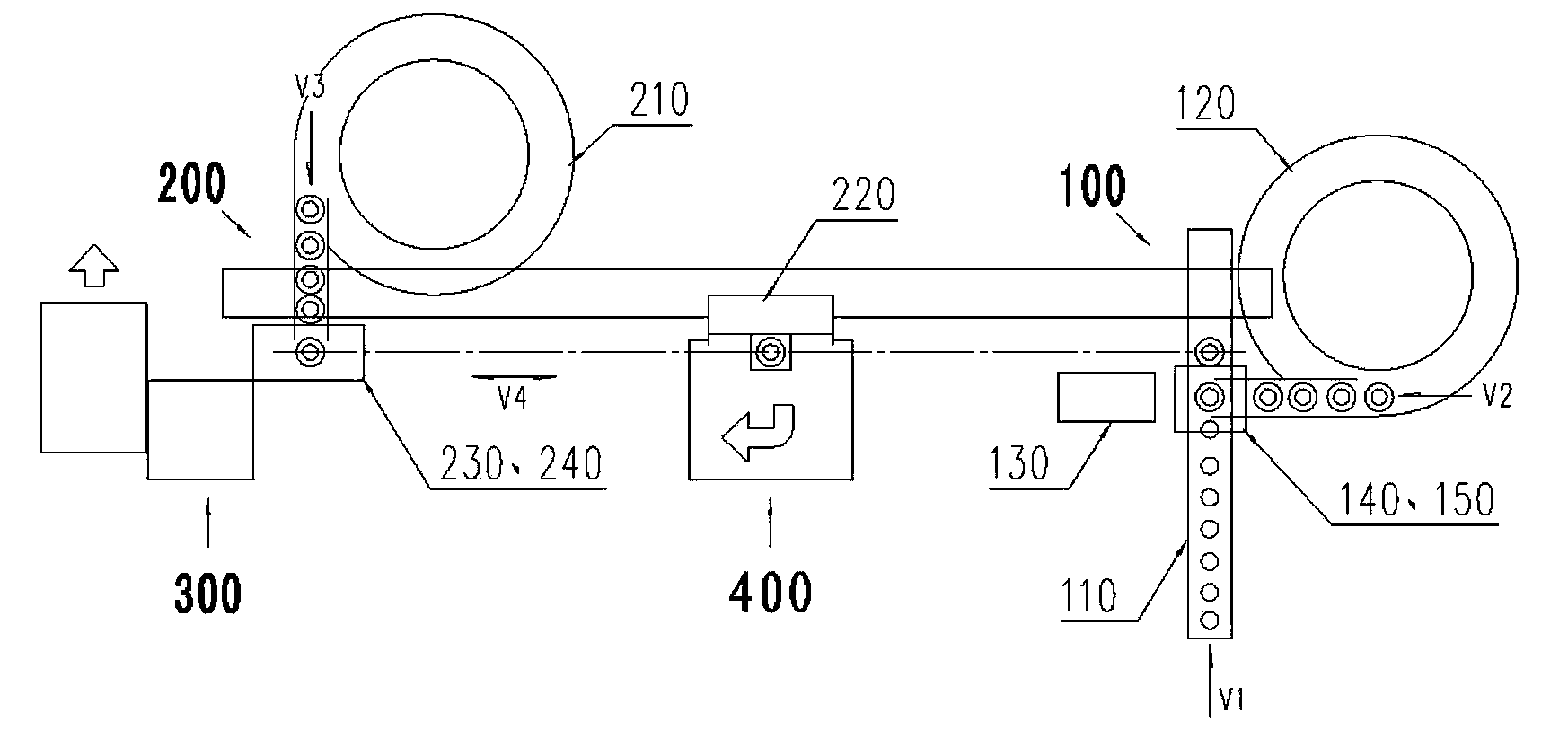

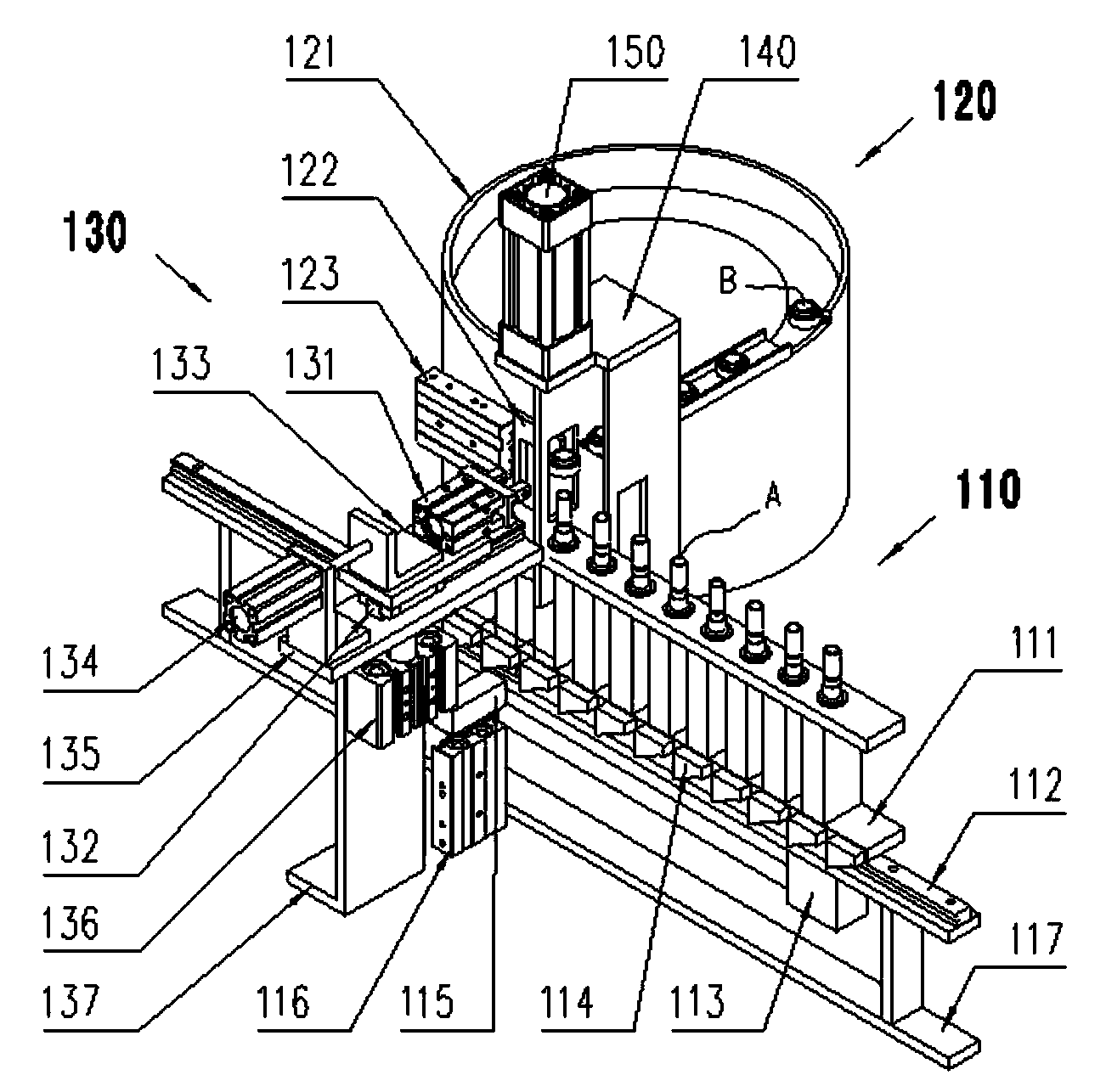

[0072] Such as figure 1 , 2 As shown, the present invention is an automatic assembly line for continuously assembling automobile cable casing fittings, including 3 sets of automatic feeding systems, 2 sets of pneumatic manipulators, and 1 set of locking mechanisms, forming 3 automatic assembly areas and 1 auxiliary assembly area. area; the first assembly area 100 and the second assembly area 200 are respectively arranged at the two ends of the second manipulator 220, the first assembly area 100 is arranged at the right end of the second manipulator 220, and the second assembly area 200 is arranged at the left end of the second manipulator 220;

[0073] The first feeding system 110 and the second manipulator 220 are arranged in a "T" shape, the second manipulator 220 is arranged horizontally, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com