Small-diameter thick wall hot rolling processing system and method

A processing method and processing system technology, applied in the field of steel pipe processing, can solve the problems of small-diameter steel pipe coil production, large steel pipe wall thickness, and low profit, and achieve the goal of improving processing quality and efficiency, increasing processing speed, and scientific design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

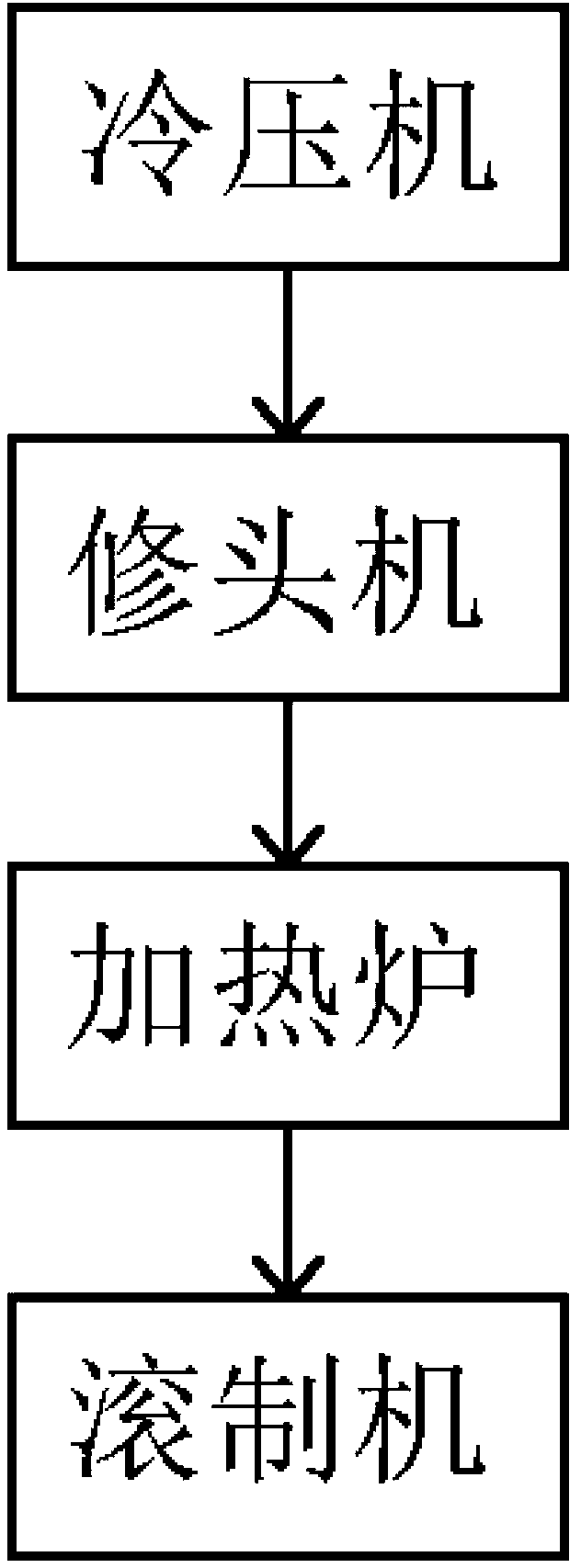

[0023] A small-diameter thick-walled hot coil processing system, including a cold press, a trimming machine, a heating furnace, and a rolling machine, the cold press, trimming machine, heating furnace, and rolling machine are arranged in sequence, and the cold pressing There are hoisting and conveying devices installed between the machine, trimming machine, heating furnace and rolling machine, which can quickly transport the coils being processed.

[0024] The above-mentioned rolling machine adopts a three-roll rolling machine, and the guide adjustment of the three pressing rollers of the rolling machine is installed on the frame, and the distance between the pressing rollers can be set according to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com