Gas compressor

A compressor and gas technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, machines/engines, etc., can solve problems such as compressor efficiency degradation, achieve the effects of reducing harmful effects, reducing wear, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description, the invention is described with reference to a piston compressor.

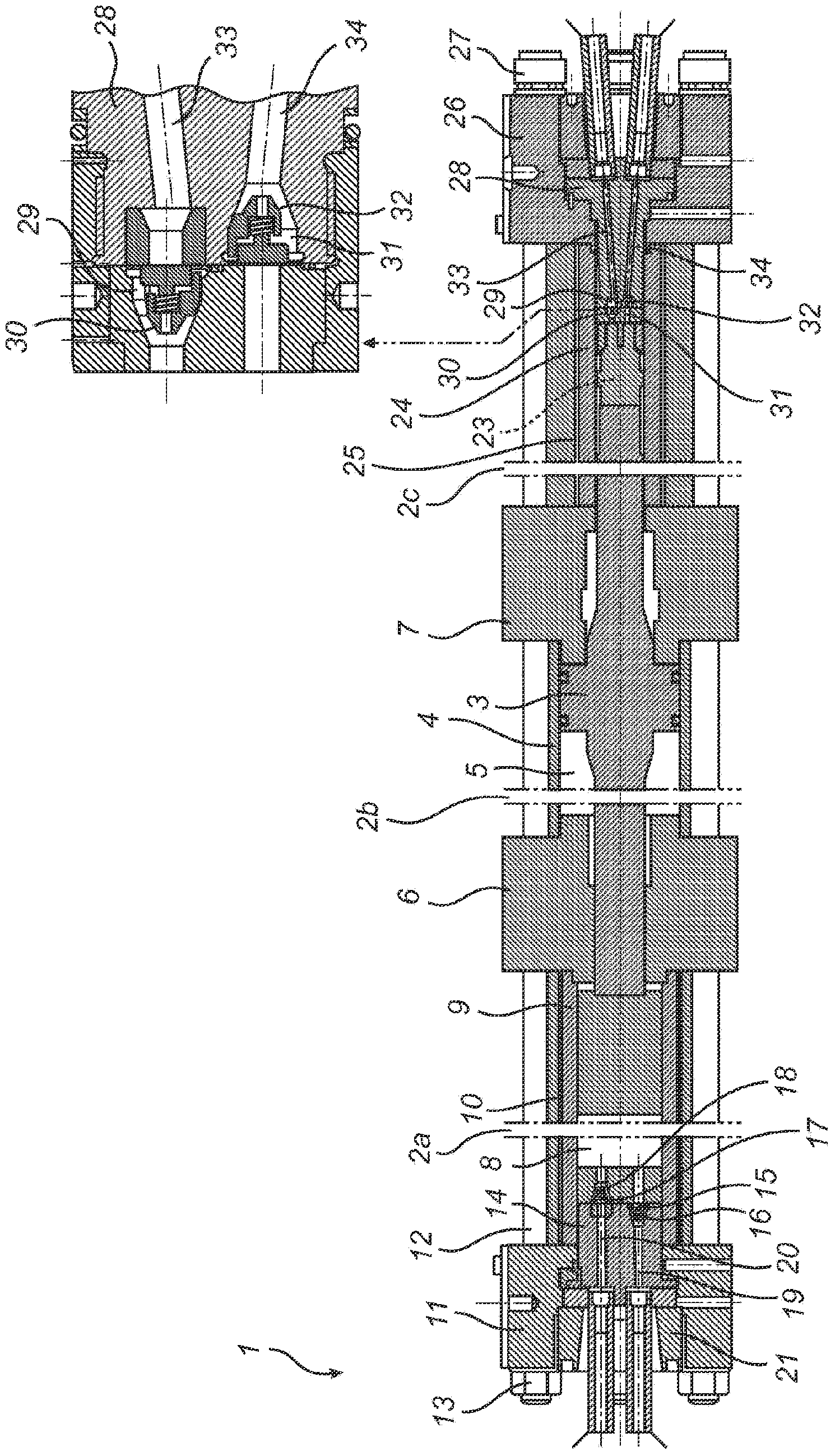

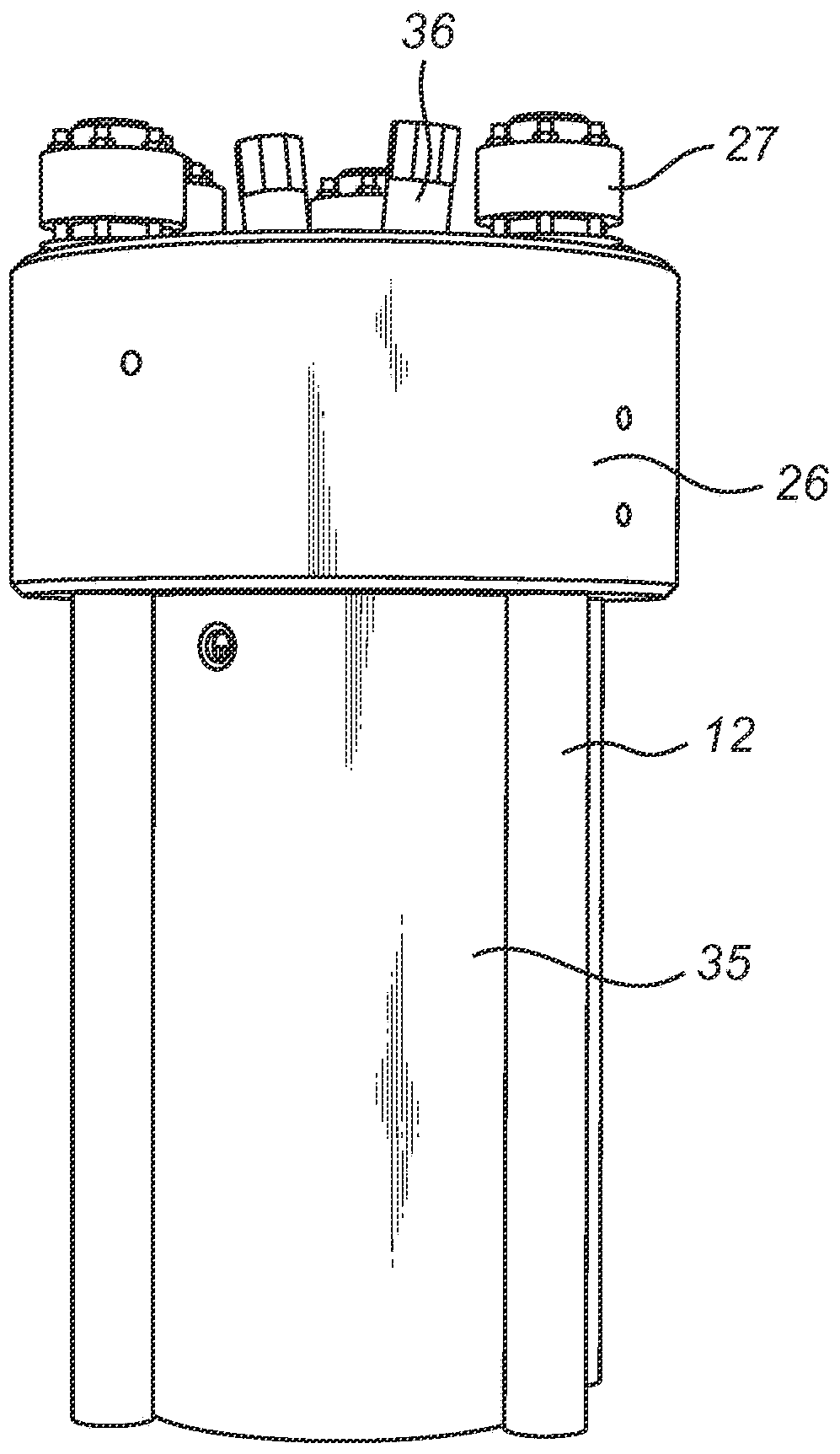

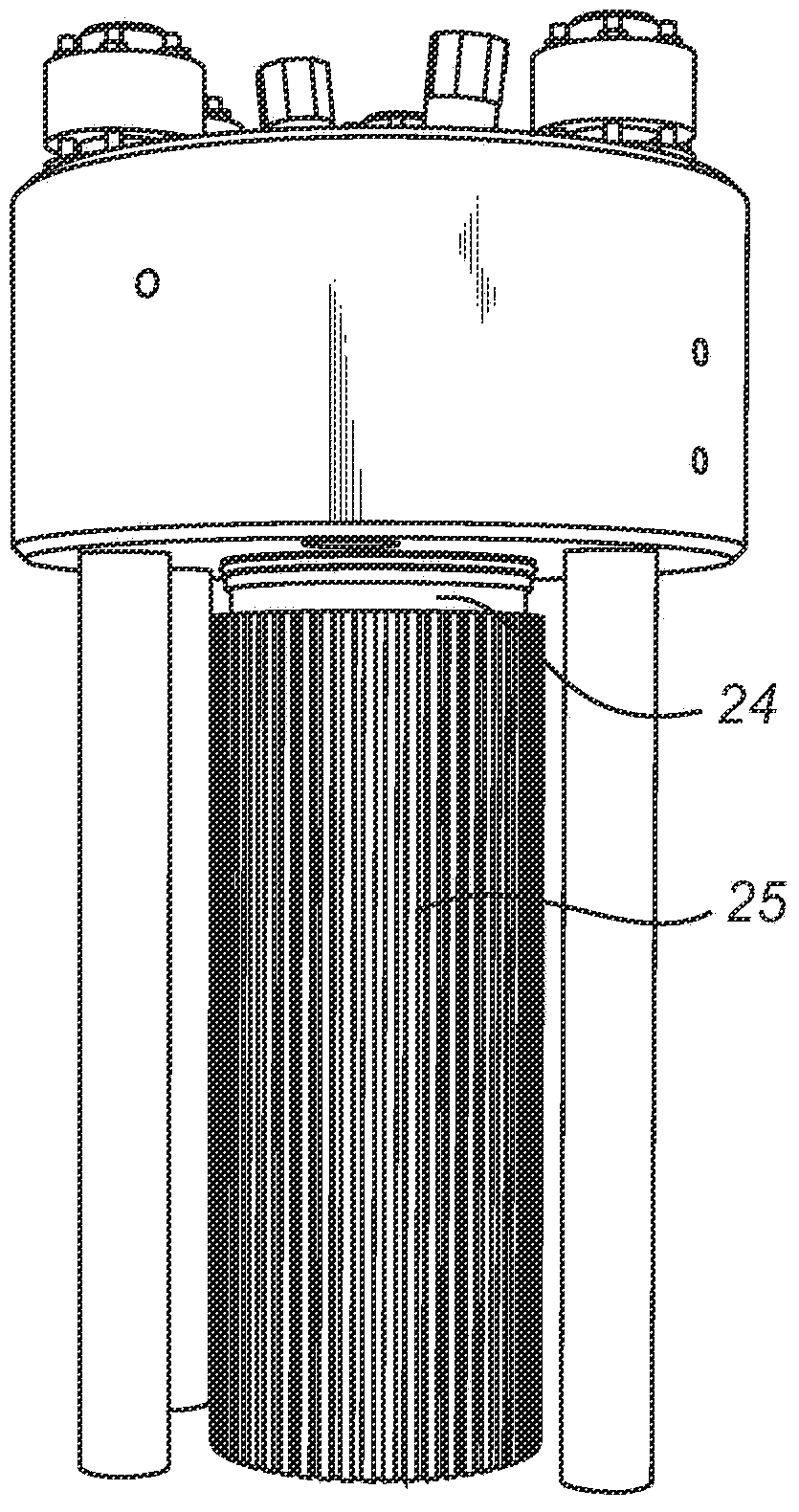

[0041] exist figure 1 , a cross-sectional view of a piston compressor 1 is shown. Since the piston compressor 1 is elongated in the horizontal direction, the drawing is provided with partitions 2a, 2b and 2c to make the drawing more compact. Therefore, taking this into consideration, the dimensional relationship in the horizontal direction in the drawings of the piston compressor 1 is explained.

[0042] In the piston compressor 1, the piston 3 is set in the central container 4, the oil is periodically pumped into the central container space 5, to both sides of the piston 3, so that the pressure from the oil forces the piston 3 in the central container Reciprocate back and forth in space 5.

[0043] A first inner gable 6 and a second inner gable 7 are arranged along the axial direction of the central container 4 , and the first inner gable 6 and the second inner gable 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com