Energy-storage energy-saving device for auxiliary start-up of rotating machinery

An energy-saving device and energy-storage technology, applied in electromechanical devices, mechanical energy control, electric components, etc., can solve problems affecting normal work, grid voltage reduction, and start-up performance that have a great impact on production, so as to improve utilization and reduce start-up The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described,

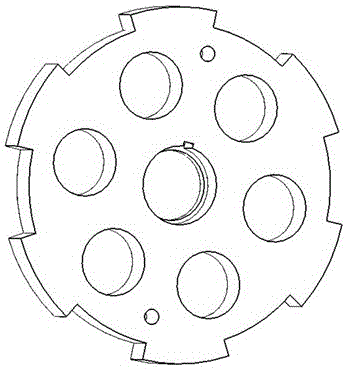

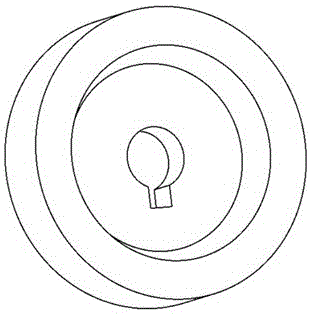

[0021] Such as figure 1 As shown, the energy-storage type energy-saving device for auxiliary start-up rotating machinery of the present invention includes a servo motor 1, an operating shaft 2, a one-way bearing 3, a scroll spring 4, a left friction device 5, a right friction device 6, a bracket 7, Bearing 8, rotary machine 9, working shaft 10, screw mandrel 11, internal screw hole 12, slider 13, spring fixing rod 14, electric push rod 15, transmission disc 16.

[0022] The center of transmission disc 16 is equipped with one-way bearing 3, is connected with transmission disc 16 by one-way bearing 3 on the working rotating shaft 10 on the rotary class machine 9, is provided with electric push rod 15 below transmission disc 16, and electric push rod 15 and The transmission discs 16 are connected in cooperation, and when energy is stored, the push rod of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com