A kind of preparation method of lithium ion secondary battery cathode material

A cathode material, secondary battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting battery capacity, insufficient coating integrity, low conductivity, amorphous carbon, etc., and achieve high cycle performance. The effect of improving electrical conductivity and good rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

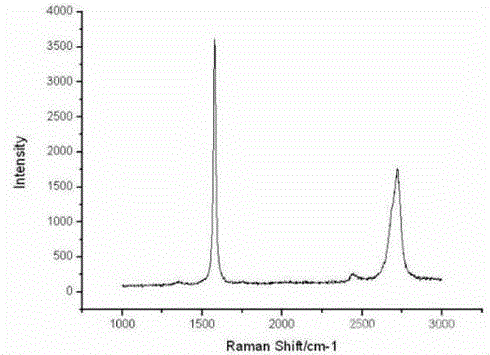

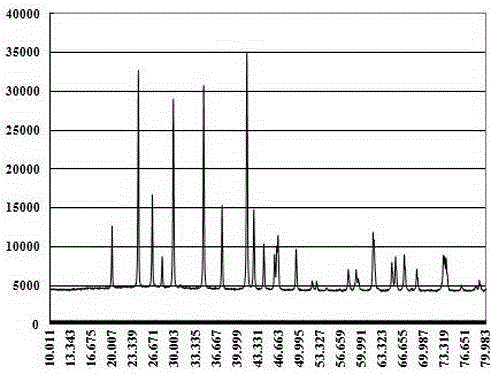

Image

Examples

Embodiment 1

[0026] A method for preparing a positive electrode material for a lithium ion secondary battery provided in this embodiment includes the following steps:

[0027] In the first step, the LiFe 0.9 PO 4 and Fe(NO 3 ) 3 .9H 2 O is dissolved in water at a molar ratio of 10:1, so that Fe(NO 3 ) 3 .9H 2 O coating in LiFe 0.9 PO 4 surface, and then the mixture particles were obtained by spray drying.

[0028] In the second step, the mixture particles obtained in the first step and methanol were placed in a reaction vessel, ultrasonically dispersed at 300° C. for 1 hour, filtered, washed, and vacuum-dried for 5 hours to obtain carburized positive electrode active material powder.

[0029] In the third step, in an argon atmosphere, the positive electrode active material powder obtained in the second step is sintered at 700 ℃, so that Fe(NO 3 ) 3 .9H 2 O and LiFe 0.9 PO 4 phase fused into crystals to the LiFe 0.9 PO 4 The surface is covered with a graphene layer to obtain...

Embodiment 2

[0031] A method for preparing a positive electrode material for a lithium ion secondary battery provided in this embodiment includes the following steps:

[0032] In the first step, the LiFe 0.95 PO 4 and FeCl 3 .6H 2 O is dissolved in water in a molar ratio of 20:1, so that FeCl 3 .6H 2 O coating in LiFe 0.95 PO 4surface, and then the mixture particles were obtained by spray drying.

[0033] In the second step, the mixture particles and ethanol obtained in the first step were placed in a reaction vessel, ultrasonically dispersed at 400° C. for 3 hours, filtered, washed, and vacuum dried for 10 hours to obtain carburized positive electrode active material powder.

[0034] In the third step, in a nitrogen atmosphere, the positive electrode active material powder obtained in the second step is sintered at 800 °C to make FeCl 3 .6H 2 O and LiFe 0.95 PO 4 phase fused into crystals to the LiFe 0.95 PO 4 The surface is covered with a graphene layer to obtain a positive ...

Embodiment 3

[0036] A method for preparing a positive electrode material for a lithium ion secondary battery provided in this embodiment includes the following steps:

[0037] In the first step, the LiFe 0.99 PO 4 and Co (NO 3 ) 3 .6H 2 O is dissolved in water in a molar ratio of 100:1 so that Co(NO 3 ) 3 .6H 2 O coating in LiFe 0.99 PO 4 surface, and then the mixture particles were obtained by spray drying.

[0038] In the second step, the mixture particles and 1,2-butanediol obtained in the first step were placed in a reaction vessel, mechanically stirred and dispersed at 180°C for 20 hours, filtered, washed, and vacuum dried for 3 hours to obtain a carburized positive electrode active material powder.

[0039] In the third step, in a hydrogen atmosphere, the positive electrode active material powder obtained in the second step is sintered at 500 °C, so that Co(NO 3 ) 3 .6H 2 O and LiFe 0.99 PO 4 phase fused into crystals to the LiFe 0.99 PO 4 The surface is covered with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com