Automatic reset differential pressure module and method for measuring wind speed and wind direction

An automatic cleaning and pressure module technology, applied in the direction of measuring fluid velocity by pressure difference, measuring devices, indicating/recording actions, etc., can solve problems such as processing and assembly difficulties, limiting measurement accuracy, and equipment use constraints, and achieve measurement accuracy and stability High performance, elimination of hysteresis nonlinear characteristics, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

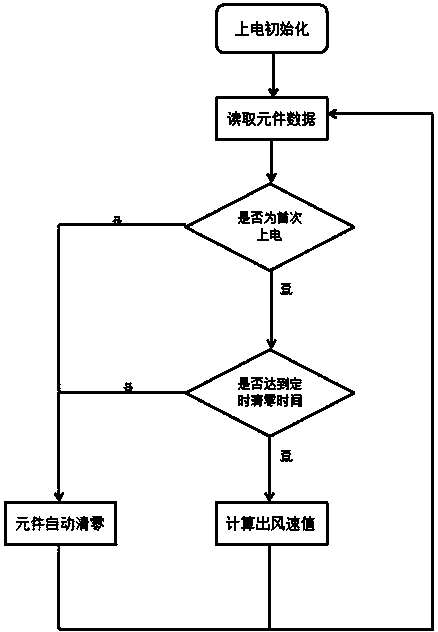

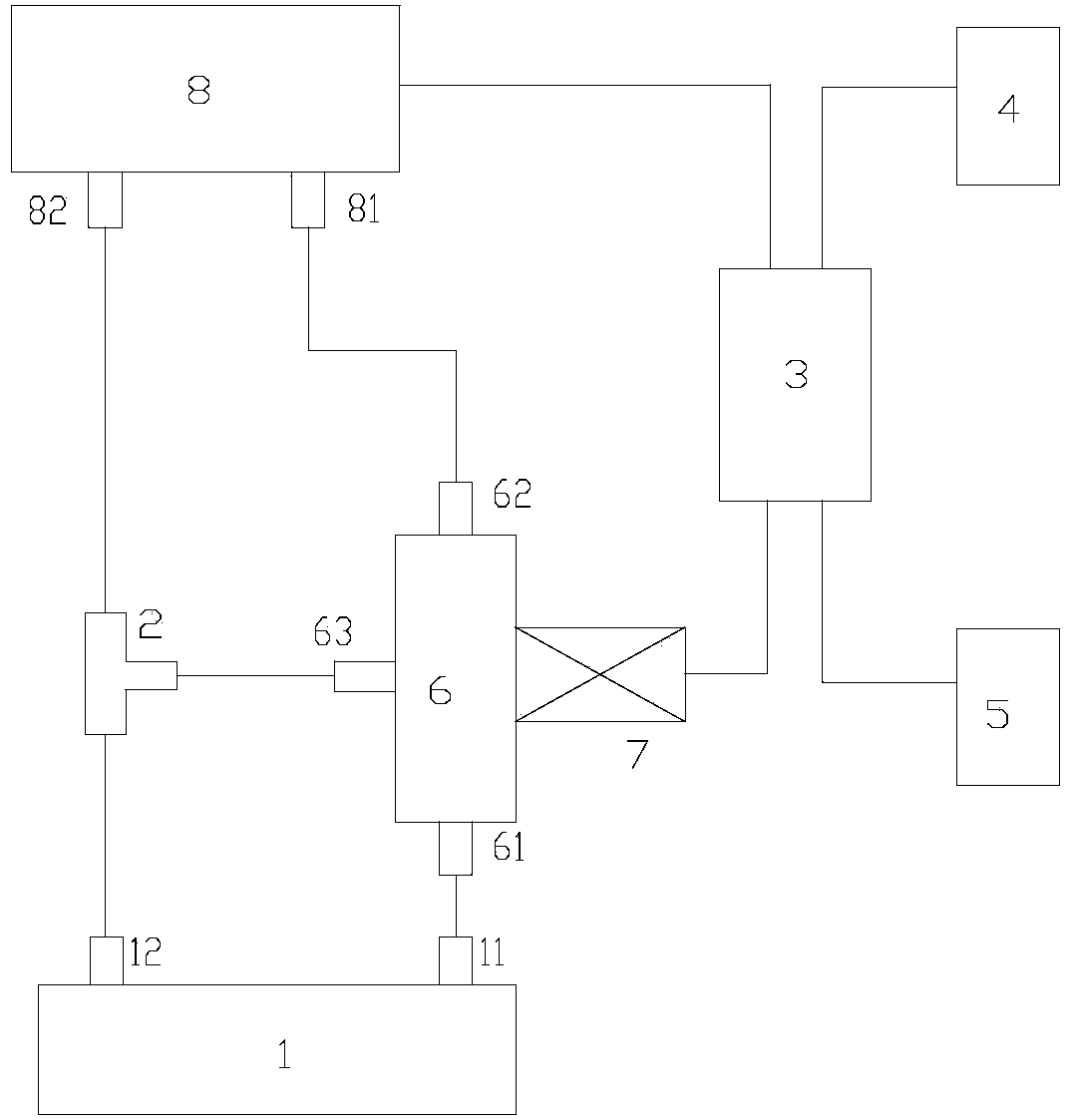

[0025] figure 1 It is a schematic block diagram of the present invention; as shown in the figure: the differential pressure module of automatic zeroing of the present invention includes an automatic zeroing assembly and a micro-pressure differential element; the micro-pressure differential element 8 is generally made of an existing pressure sensor, and here No longer;

[0026] The micro-pressure differential element has a sampling port I81 and a sampling port II82;

[0027] The automatic zeroing component is provided with interface I61, interface II62 and interface III63, the interface I61 is connected to the high-pressure sampling port 11 of the probe 1, the interface II62 is connected to the sampling port I81, and the interface III63 is connected to the sampling port II82; the sampling port II82 is also It is connected to the low-pressure sampling port 12 of the probe 1, and the interface I61 and the interface III63 can be connected or closed with the interface II62 by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com