Bath water waste heat recoverer

A waste heat recovery, heat exchanger technology, used in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

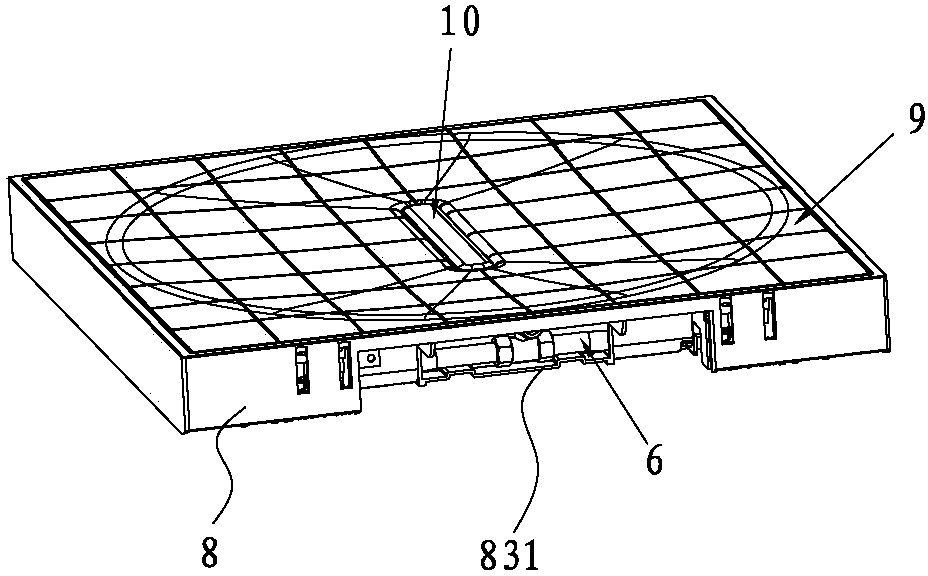

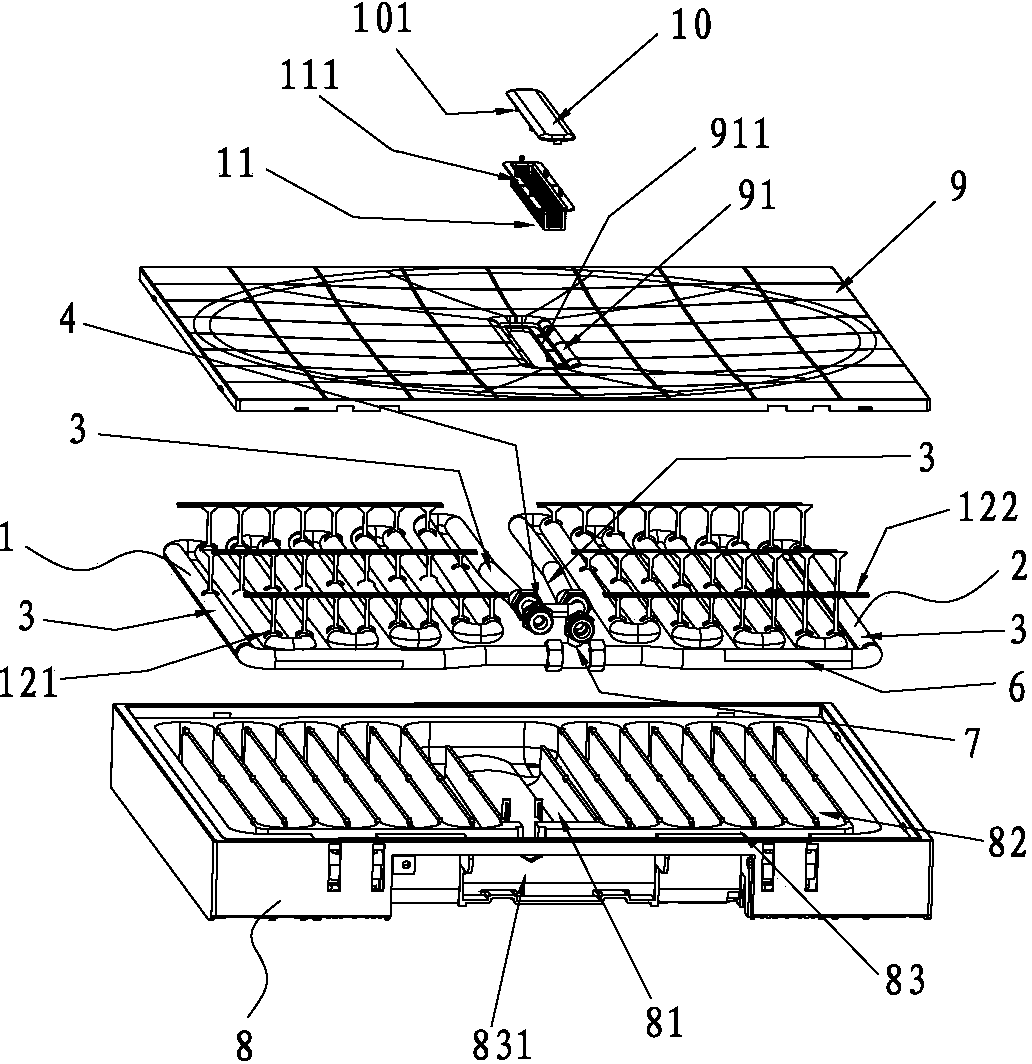

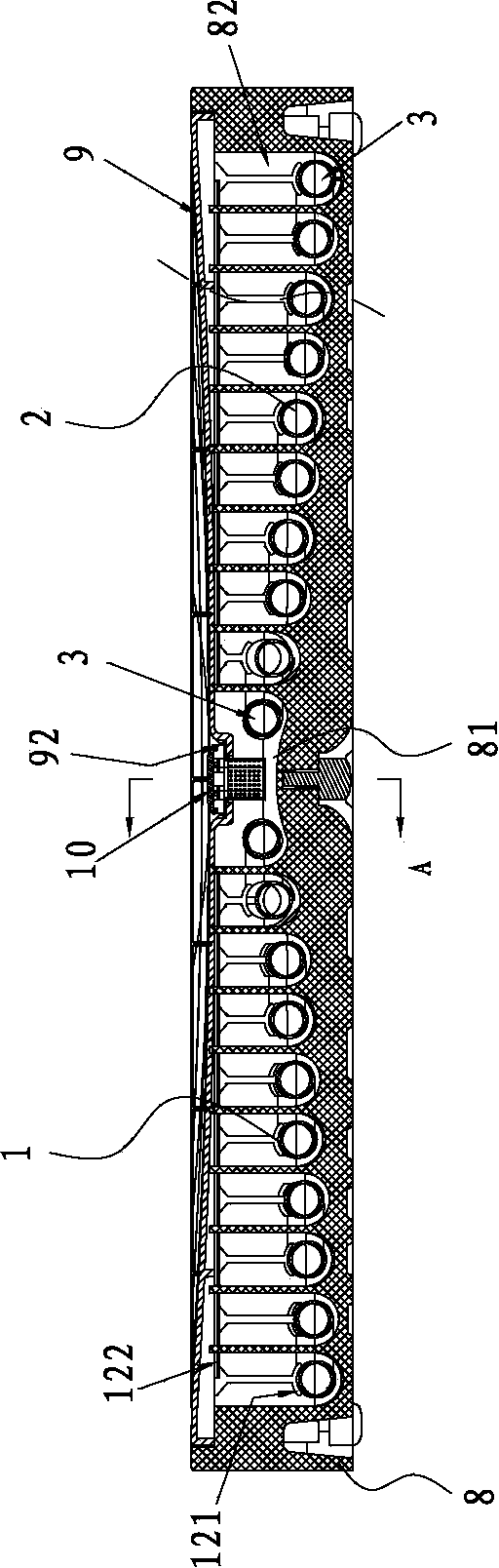

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown in the figure, a waste heat recovery device for waste water includes a heat exchanger made of reciprocating bending of metal pipes and a plurality of heat exchange branch pipes connected in series. The heat exchanger is divided into a left heat exchanger 1 and a right heat exchanger 2 , the parallel structure of left and right heat exchangers; the heat exchange branch pipes 3 at the water outlets of the left and right heat exchangers 1 and 2 are adjacent and connected to the water outlet port 4, and the heat exchange branch pipes 3 at the water inlet end are connected through a connecting pipe 6 Connecting pipe 6 is provided with a water inlet port 7, and the water inlet port 7 is connected with the water source;

[0034] The heat exchange branch pipe is a corrugated heat exchange branch pipe.

[0035] It also includes a heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com