Nuclear power plant start and stop feed water pump

A technology for nuclear power plants and water supply pumps, which is applied to pumps, pump components, non-variable pumps, etc. It can solve the problems of long disassembly and assembly time, shorten maintenance time, increase erosion resistance, and stabilize working characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

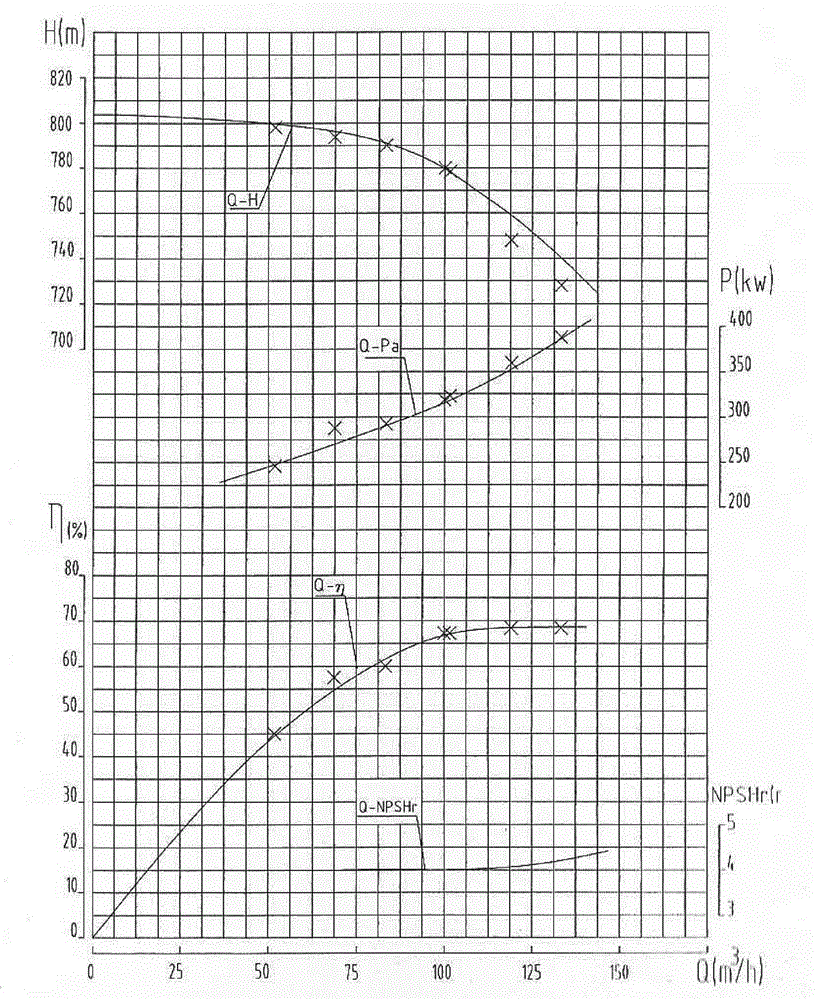

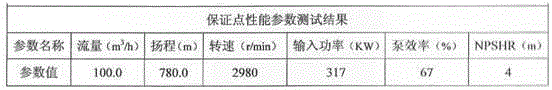

Image

Examples

Embodiment

[0025] Such as figure 1 As shown, a double-casing horizontal multistage centrifugal pump is adopted, and the number of impeller stages is 6; it includes a cylinder body 15 and a core package, and the core package is integrated inside the cylinder body 15, and the cylinder body 15 and the end cover 16 pass through the stud 17 , nut 18 and washer 19 are fixed; clamping plate 11 and cylinder 15 are fixed by pins; The pump inlet and the pump outlet are arranged vertically upward; the overflow part of the cylinder is surfacing with an erosion-resistant Aussie stainless steel layer; the core package structure is that one end of the pump shaft 20 is provided with a mechanical seal I22 and a drive end Bearing assembly 21, the other end of pump shaft 20 is provided with mechanical seal II and free end bearing assembly 23; suction section 1, middle section, balance mechanism and pressure plate 14 are sequentially installed on pump shaft 20, suction section 1 and drive end bearing assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com