Dust hood for textile machine

A technology for vacuum hoods and textile machines, which is applied in textiles, textiles, papermaking, and auxiliary weaving equipment. It can solve the problems of wool sticking to the cloth, affecting the work of workshop personnel, and being scattered on the operator's body or on the ground. The effect of clean working environment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

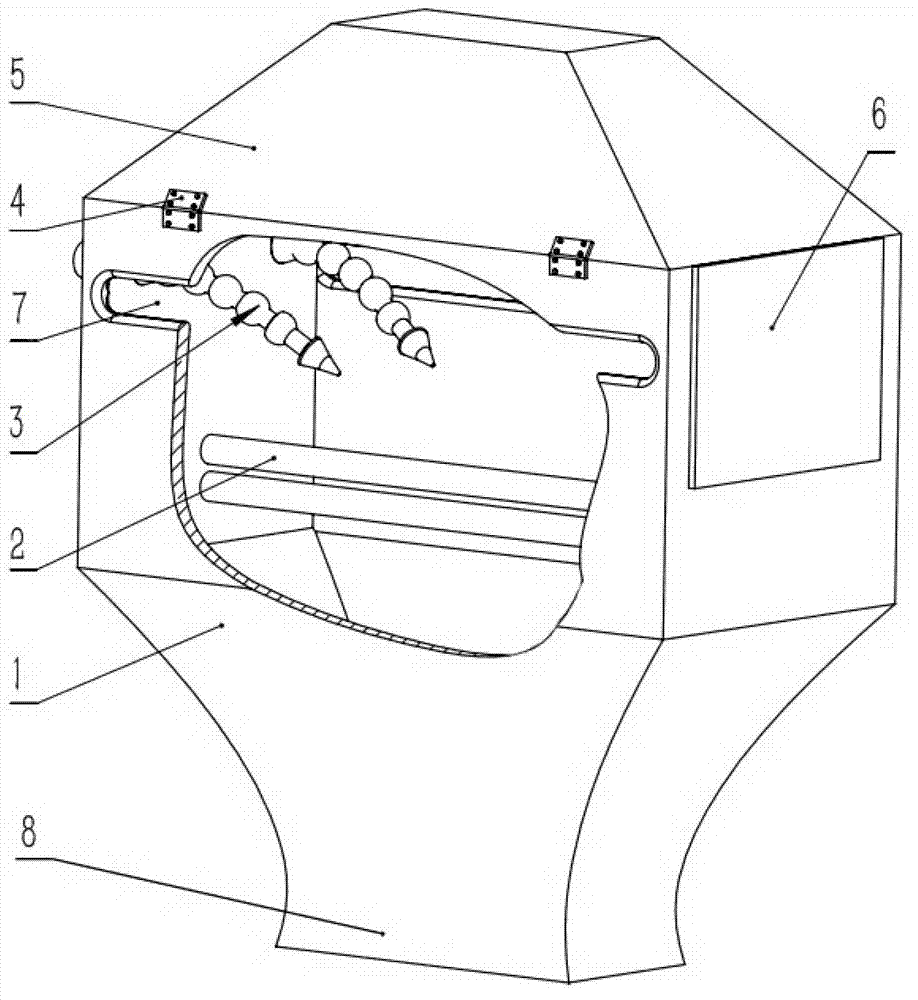

[0012] Example: see figure 1 As shown, a dust collection hood for a textile machine includes a case 1, the lower end of the case 1 is formed with a dust suction port 8, the upper end of the case 1 is hinged with a case cover 5 through a hinge 4, and a support rod is fixed inside the case 1 2. The casing 1 on the left and right sides of the pole 2 is formed with a waist-shaped long groove 7; the casing 1 at the rear end of the pole 2 is inserted with a serpentine tube 3; the casing 1 at the front end of the pole 2 is provided with Watch window 6.

[0013] The strut 2 is composed of two circular tubes arranged up and down.

[0014] The length of described elongated groove 7 is greater than the width of cloth.

[0015] Working principle: Pass the cloth through the long slot 7, the support rod 2, and the long slot 7 in sequence, close the shell cover, connect the serpentine tube 3 to the blowing device, and connect the dust suction port 8 to the suction device. The serpentine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com