A control method and control system for the production environment of lpcvd process

A control method and technology of production environment, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of long control time and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

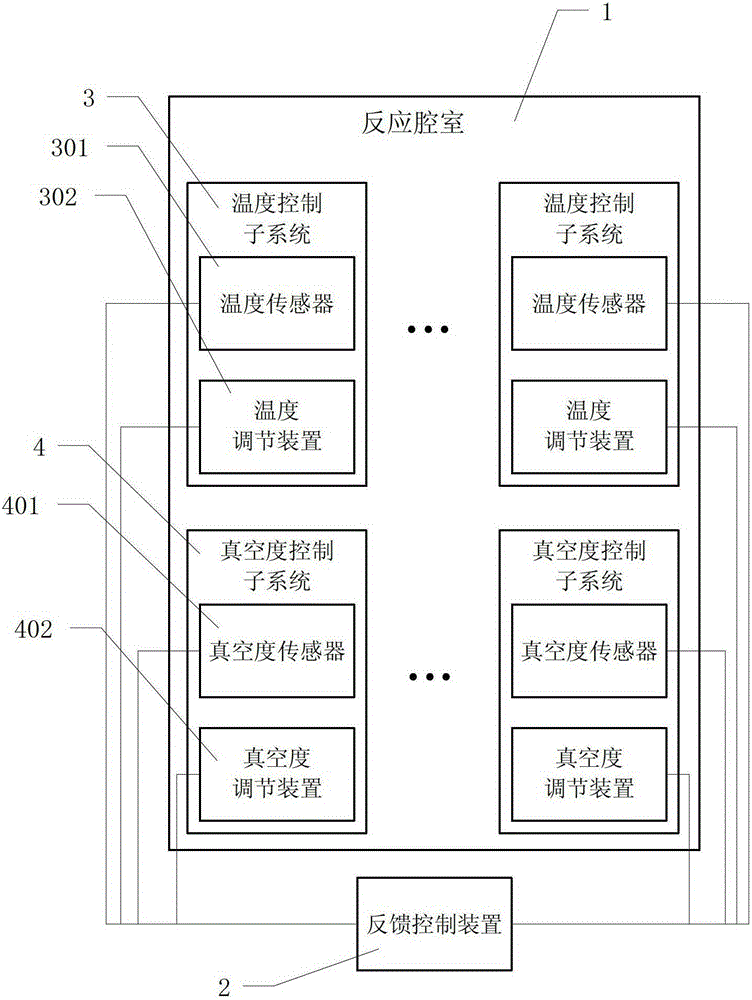

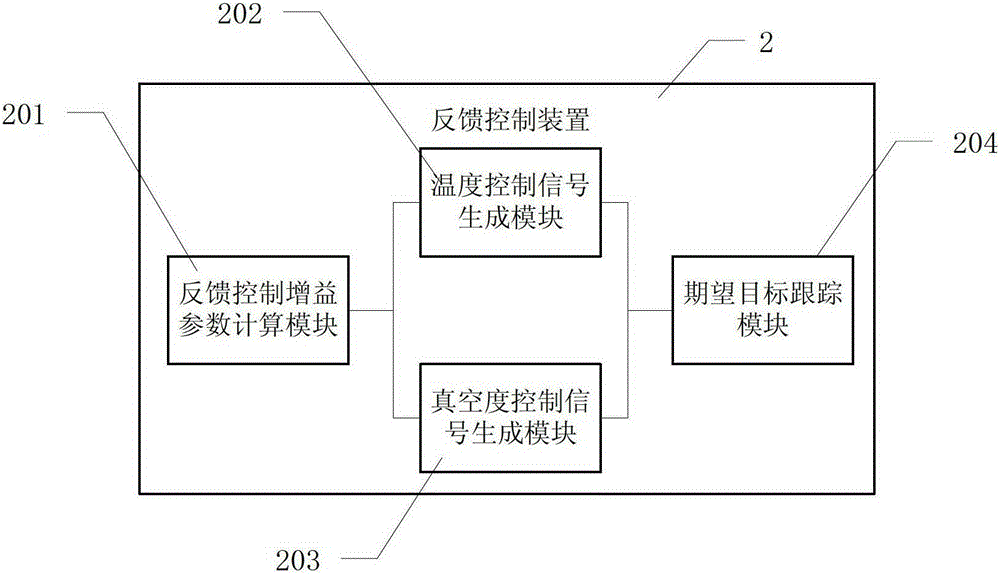

[0076] The embodiment of the present invention provides a method for controlling the production environment of the LPCVD process, the control method is applied to the control system of the production environment of the LPCVD process, and the control system includes a closed reaction chamber, a feedback control device, and G temperature control subsystems And H vacuum control subsystems, G and H are positive integers; the temperature control subsystem includes a temperature sensor and a corresponding temperature adjustment device, and the vacuum control subsystem includes a vacuum sensor and a corresponding Vacuum adjustment device;

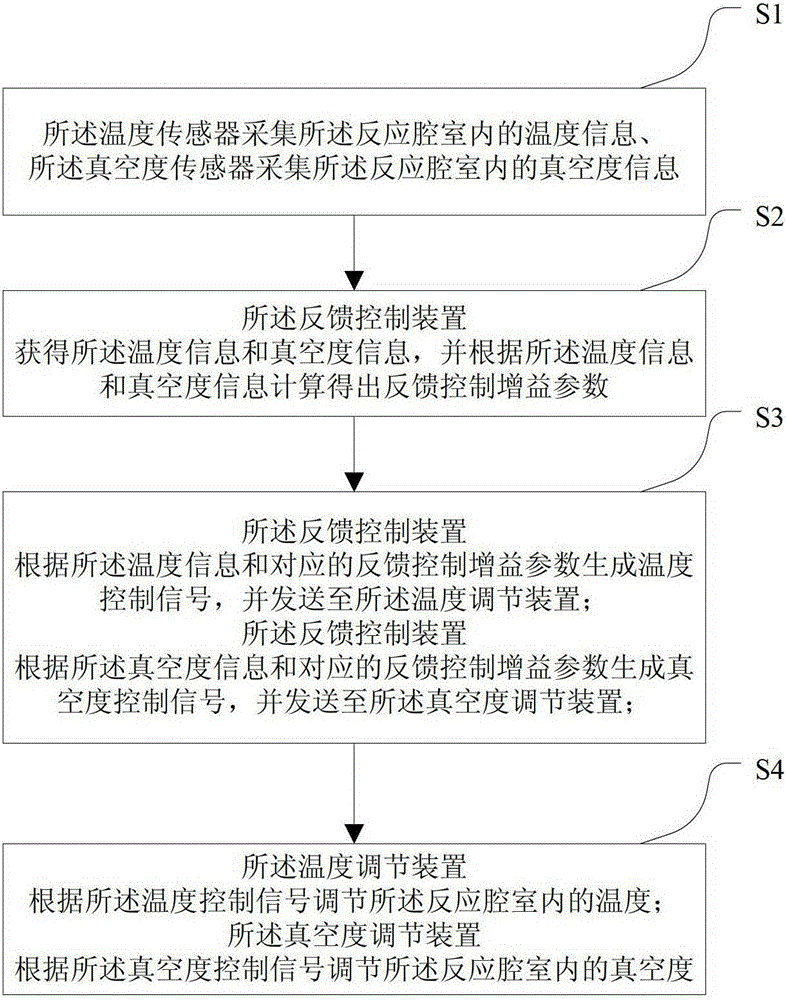

[0077] figure 1 is a flow chart of the control method described in the embodiment of the present invention, such as figure 1 As shown, the control method inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com