Leather pulp shooting machine

A shotcrete machine and leather technology, which is used in leather drying, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc., can solve problems such as exhaust gas pollution, and achieve improved production efficiency, uniform dyeing and good spraying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

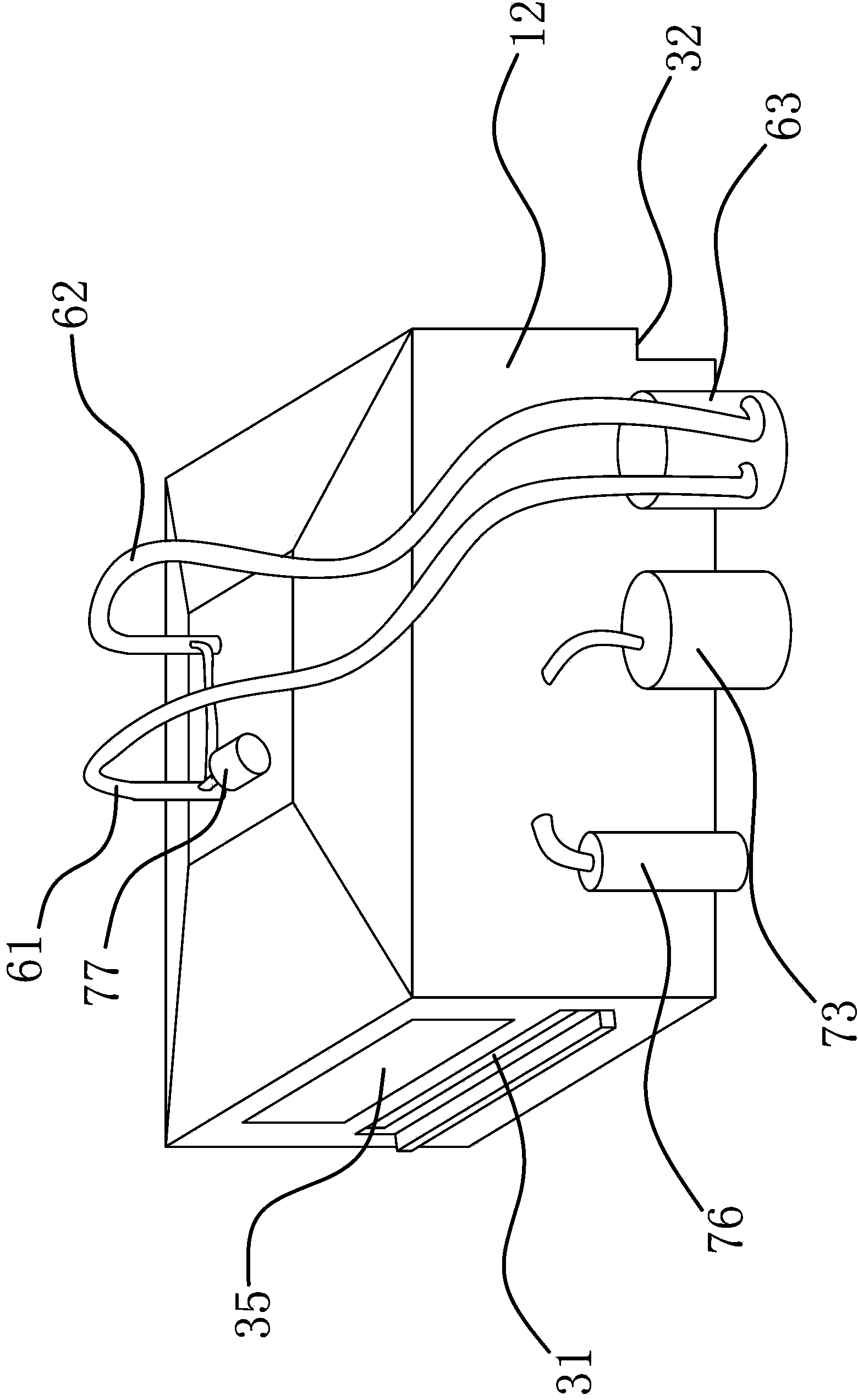

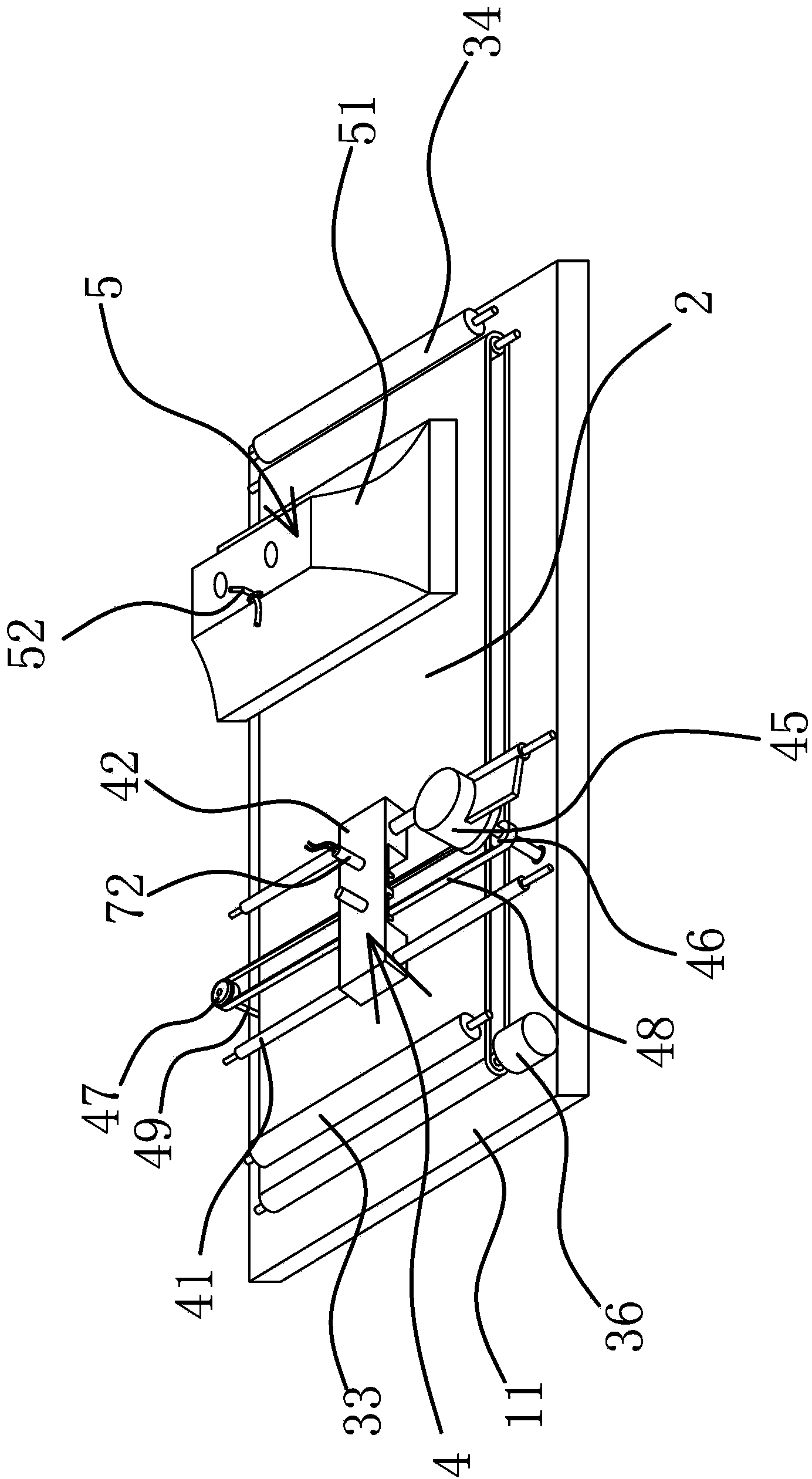

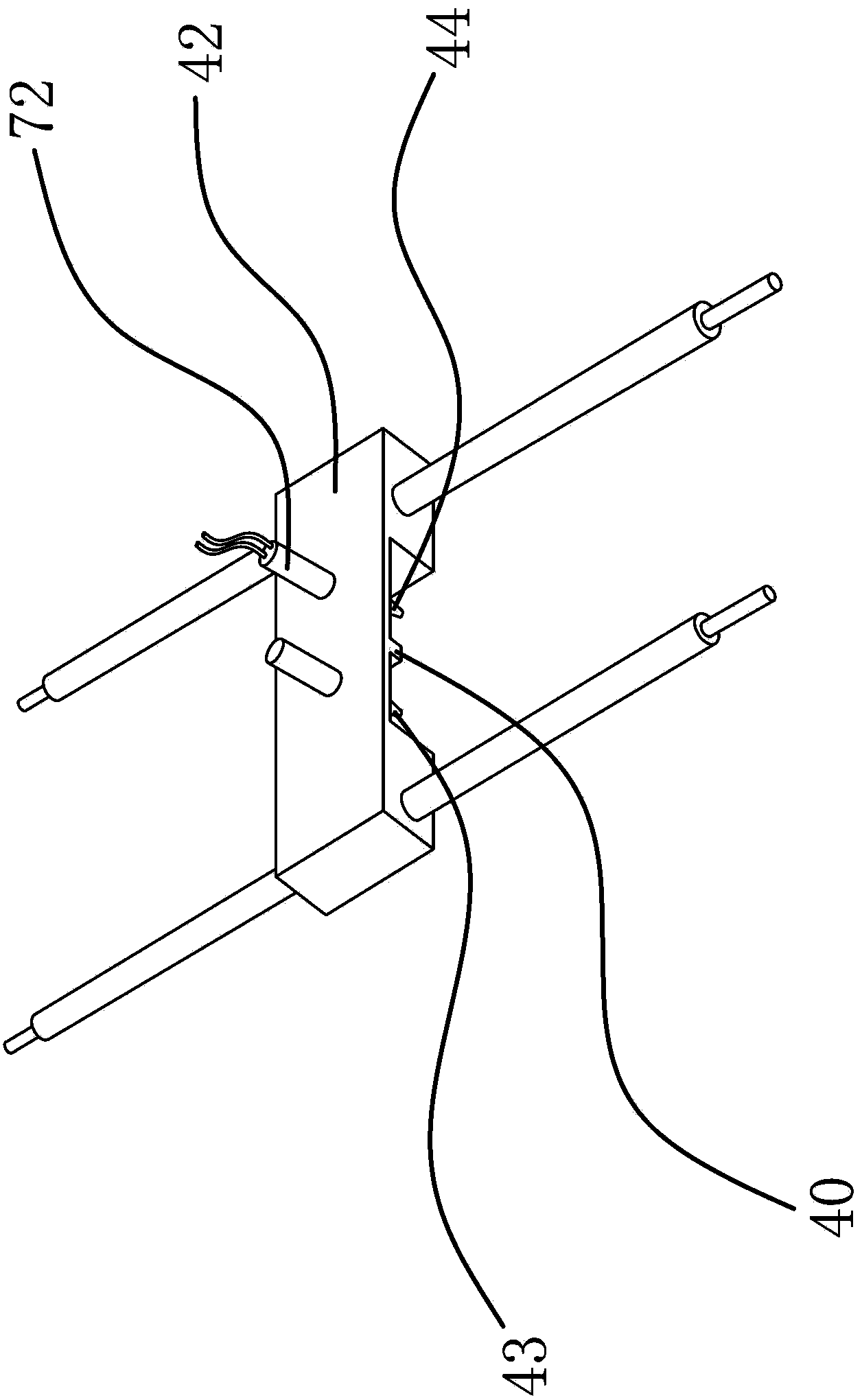

[0028] Such as figure 1 , figure 2 with image 3 As shown, the leather spraying machine includes a bottom plate 11 and a sealing seat 12 sleeved on the bottom plate 11. A conveyor belt 2 is provided on the bottom plate 11, one end of the sealing seat 12 is provided with a discharge port 31, and the other end of the sealing seat 12 A discharge port 32 is provided, a spraying mechanism 4 and a drying mechanism 5 are provided in the sealing seat 12, and the top of the sealing seat 12 is provided with a dust discharge pipe 61 and an exhaust gas discharge pipe 62 communicating with the inside of the sealing seat 12. A decontamination cylinder 63 is provided on the outer wall of the sealing seat 12, and both the dust and slag discharge pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com