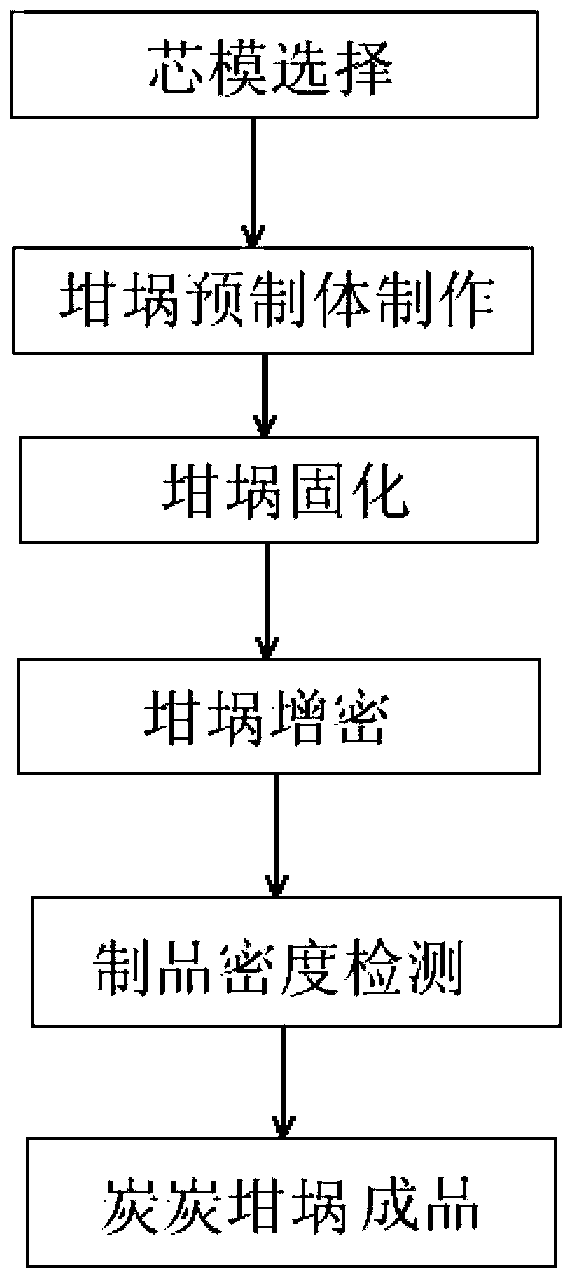

Manufacturing method of carbon/carbon crucible

A production method and crucible technology, which are applied in the field of carbon-carbon crucible production, can solve problems such as poor stability, fragile graphite, and short service life of the crucible, and achieve the effects of uniform thickness, beautiful appearance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

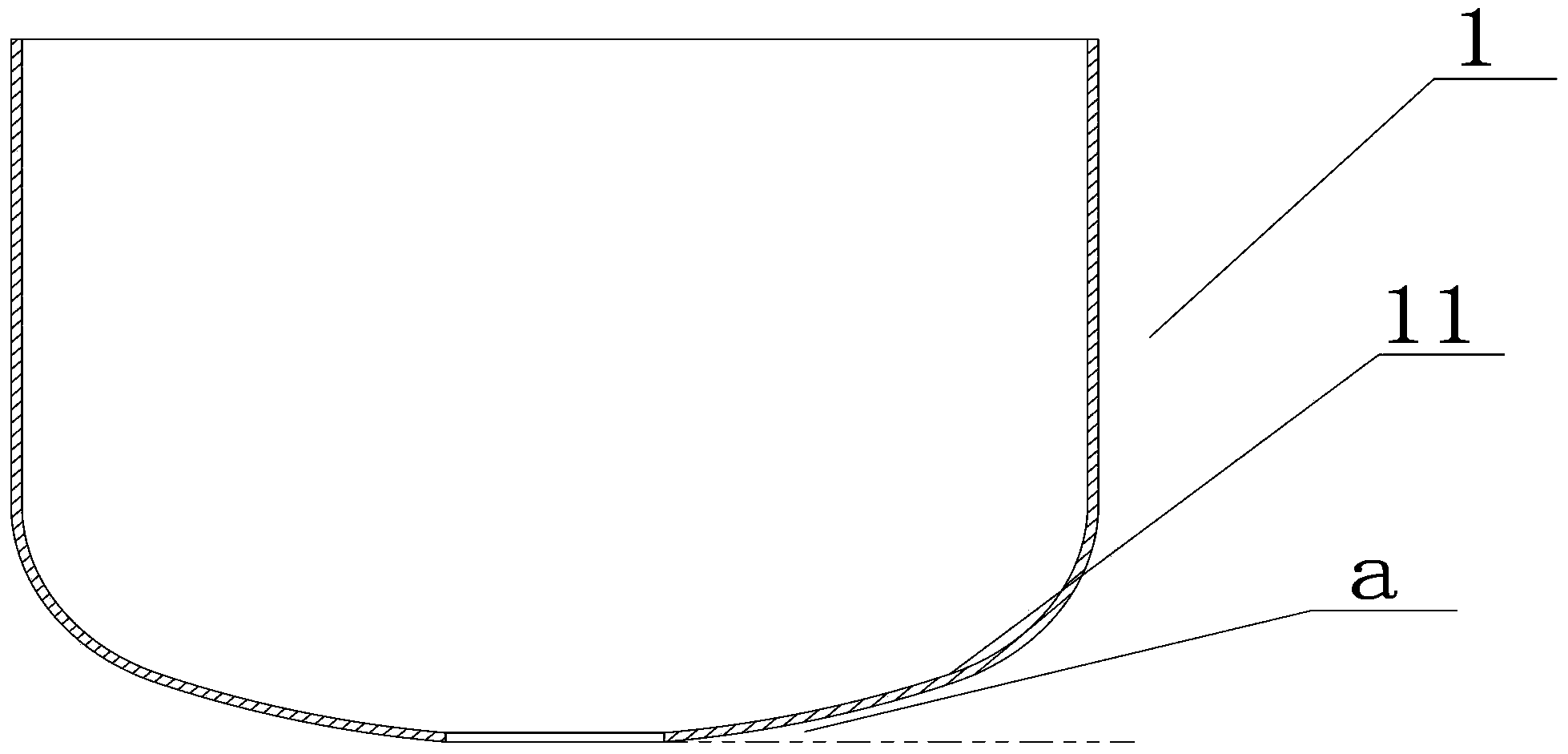

[0037] Take making a kind of thickness be 3mm, inner diameter is the carbon charcoal crucible of 10 inches as example, and its manufacturing method comprises the following manufacturing steps:

[0038] 1) Mandrel selection: According to the size of the charcoal crucible to be made, select a stainless steel mandrel with an outer diameter of 25.4cm, and evenly coat the outer surface of the mandrel with a 0.1-0.3mm thick water-based polyurethane release agent. winding

[0039] 2) Manufacture of crucible prefabricated body: install the mandrel in step 1) on the winding machine, select carbon fiber with 12K tow, and its spreading width is 8mm, and the number of winding layers required to be wound is determined to be 8 through calculation, and the winding process as follows:

[0040] a. Winding the first layer: Wind the carbon fiber on the surface of the mandrel at an angle of 30°, and the winding pressure is 2N;

[0041] b. Winding the second layer: the carbon fiber is at an angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com