High-speed and down-flow type sludge back-mixing anaerobic reactor

An anaerobic reactor and reverse mixing technology, applied in the field of anaerobic reaction, can solve the problems of anaerobic sludge loss, low efficiency, short circuit of water flow, etc., to achieve stable effluent quality, improve treatment efficiency, and avoid sludge deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

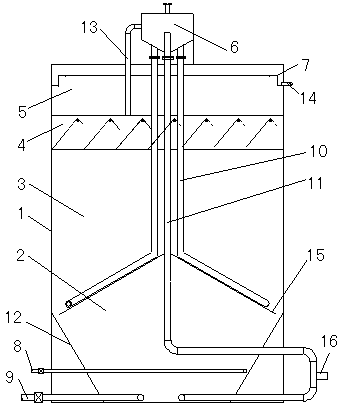

[0014] As shown in the accompanying drawings, the high-speed sinking flow sludge reverse mixing anaerobic reactor of the present invention is columnar and adopts a steel structure, mainly including a columnar main body 1 with a height-to-diameter ratio of 1:1-1:4. The main body 1 is provided with a downflow reaction zone 2 , an upflow reaction zone 3 , a gas-solid-liquid separation zone 4 and a sedimentation separation water zone 5 from bottom to top. The sinking flow reaction zone 2 is formed by a bucket-shaped body 12 opening upwards and a cone-shaped cover 15 opening downwards. There is a gap between the bucket-shaped body 12 and the cone-shaped cover 15 for passing muddy water. The gas-solid-liquid separation zone 4 is provided with a three-phase separator. A water outlet weir 7 is arranged above the sedimentation separation water outlet area 5 , and an outlet pipe 14 is arranged on the outlet weir 7 . A lower gas-solid-liquid separation zone can also be set between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com