A roof beam structure and boat electrophoresis method

A beam and roof technology, applied in the directions of electrophoretic plating, upper structure, and upper structure sub-assembly, can solve problems such as the expansion angle should not be too large, the gas cannot be discharged, and the structural strength is affected, so as to avoid the occurrence of air pockets. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

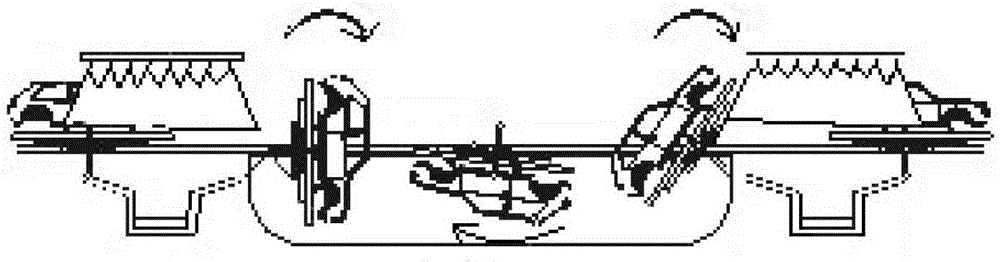

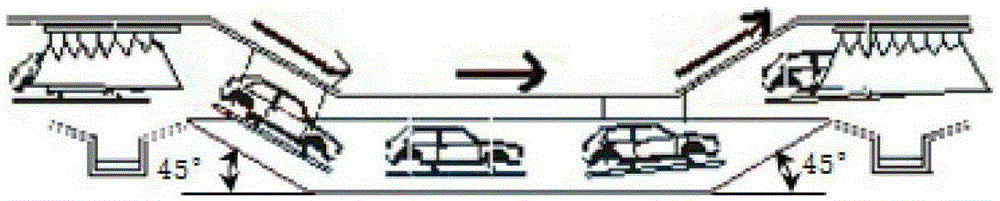

[0028] combine figure 1 , figure 2 , which respectively show the flipping electrophoresis process and the "boat" electrophoresis process of the body-in-white. Depend on figure 1 It can be seen that during flipping electrophoresis, the body-in-white is moving forward in the electrolyte such as figure 1 The direction indicated by the middle arrow is flipped for at least one week. This process can ensure that all the air in all parts of the body-in-white is discharged without causing cavitation. However, at the same time, flipping electrophoresis has the disadvantage of insufficient thickness of the electrophoretic film on the lower part of the body-in-white. Depend on figure 2 It can be seen that in the "boat" type electrophoresis, according to figure 2 In the direction indicated by the middle arrow, the body-in-white enters the tank at a certain angle, and after being fully immersed in the electrolyte, it exits the tank at a certain angle. Generally, the angle of entry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com