Coil box equipment double-interlock protection device and control method thereof

A technology of protection device and hot coil box, which is applied in the direction of rolling mill control device, metal processing equipment, roll safety equipment, etc., and can solve the problems of sensor detection failure, interruption, equipment damage and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

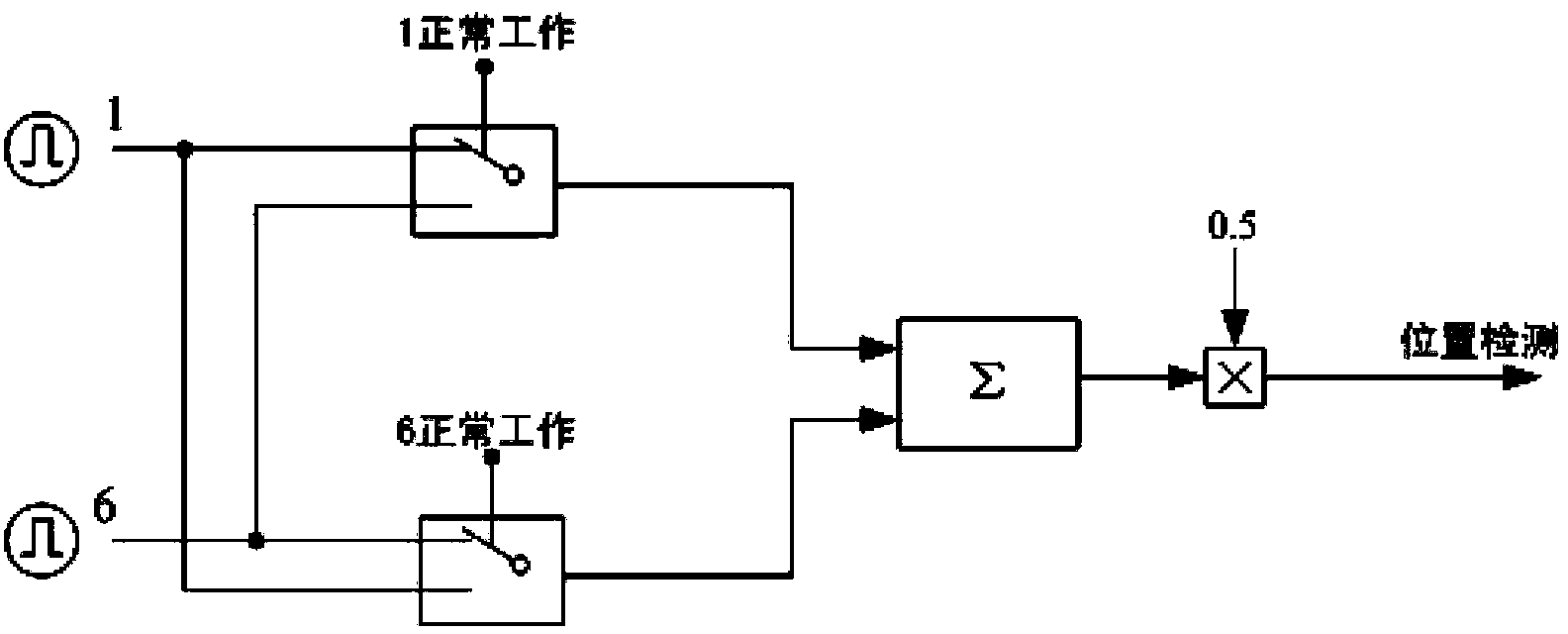

[0023] The embodiment of the present invention mainly adds a position sensor on the operation side, and uses the logic and data operation of PLC to automatically switch to the sensor on the operation side when the original transmission side position sensor fails to avoid detection failure, so as to maintain the safety and reliability of the equipment. Production continues. It is suitable for similar equipment such as hot-rolled plate coil boxes to ensure stable, safe and reliable operation of the equipment.

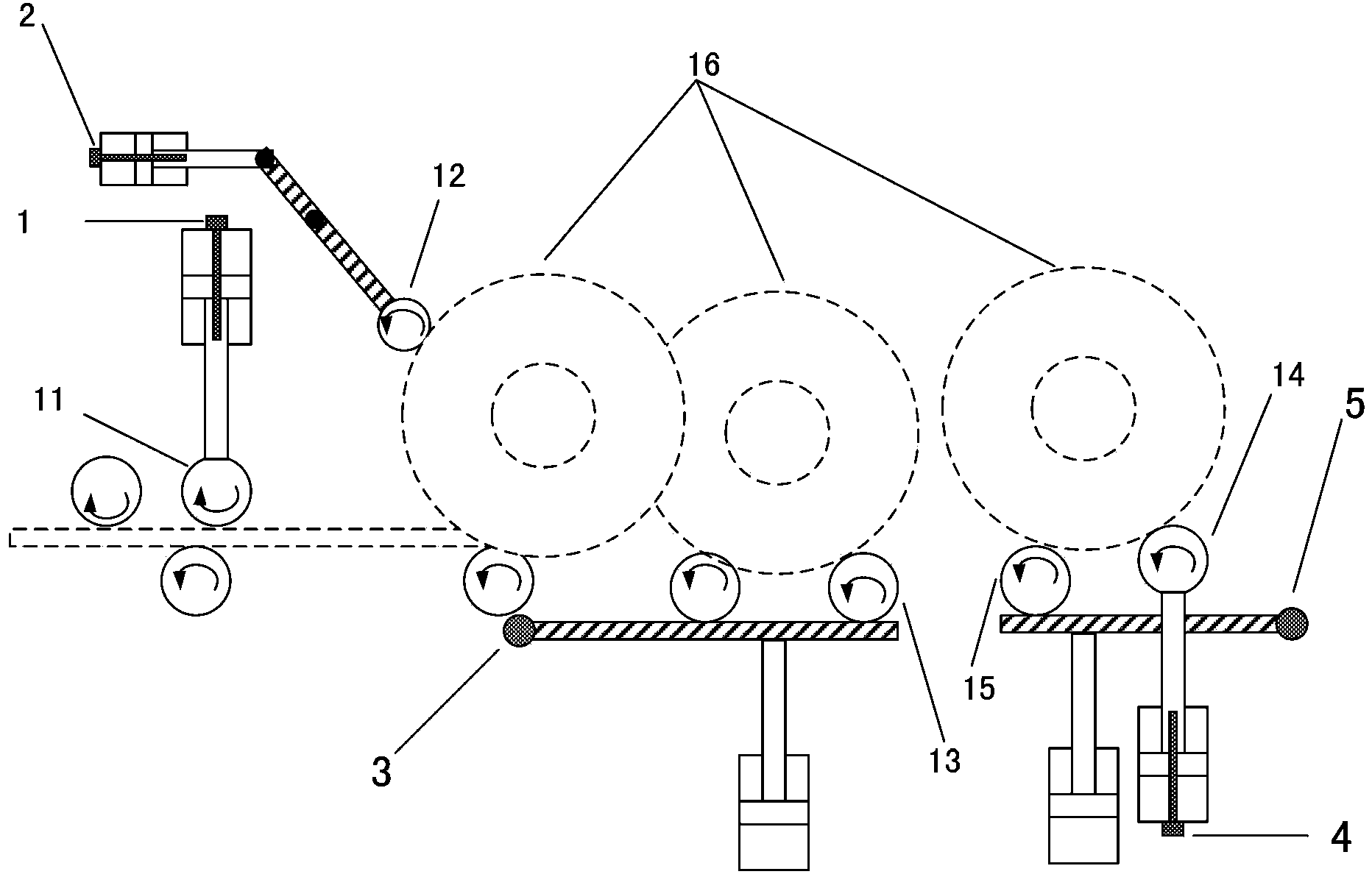

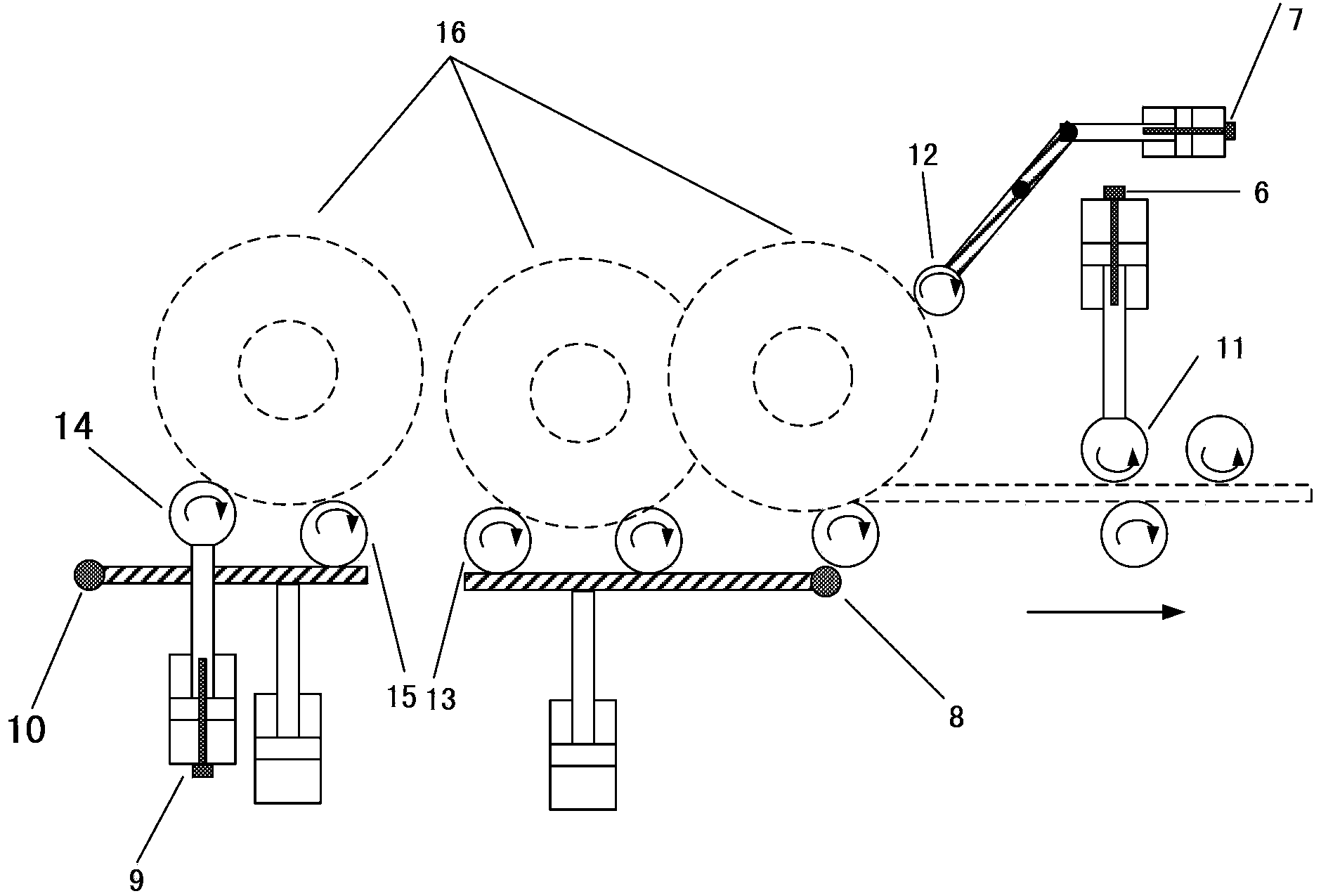

[0024] as attached figure 1 and 2 shown are the left (transmission side) and right (operation side) views of the double interlocking protection device of the hot coil box equipment according to the embodiment of the present invention, the device includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com