High frequency pulse power supply for electric dedusting

A high-frequency pulse and power supply technology, applied in power supply technology, electrostatic separation, etc., can solve the problems that the dust removal effect of the dust collector cannot be better improved, the dust absorption effect of high specific resistance is poor, and the dust absorption effect is general, etc., to achieve Improve power utilization, reduce energy consumption, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

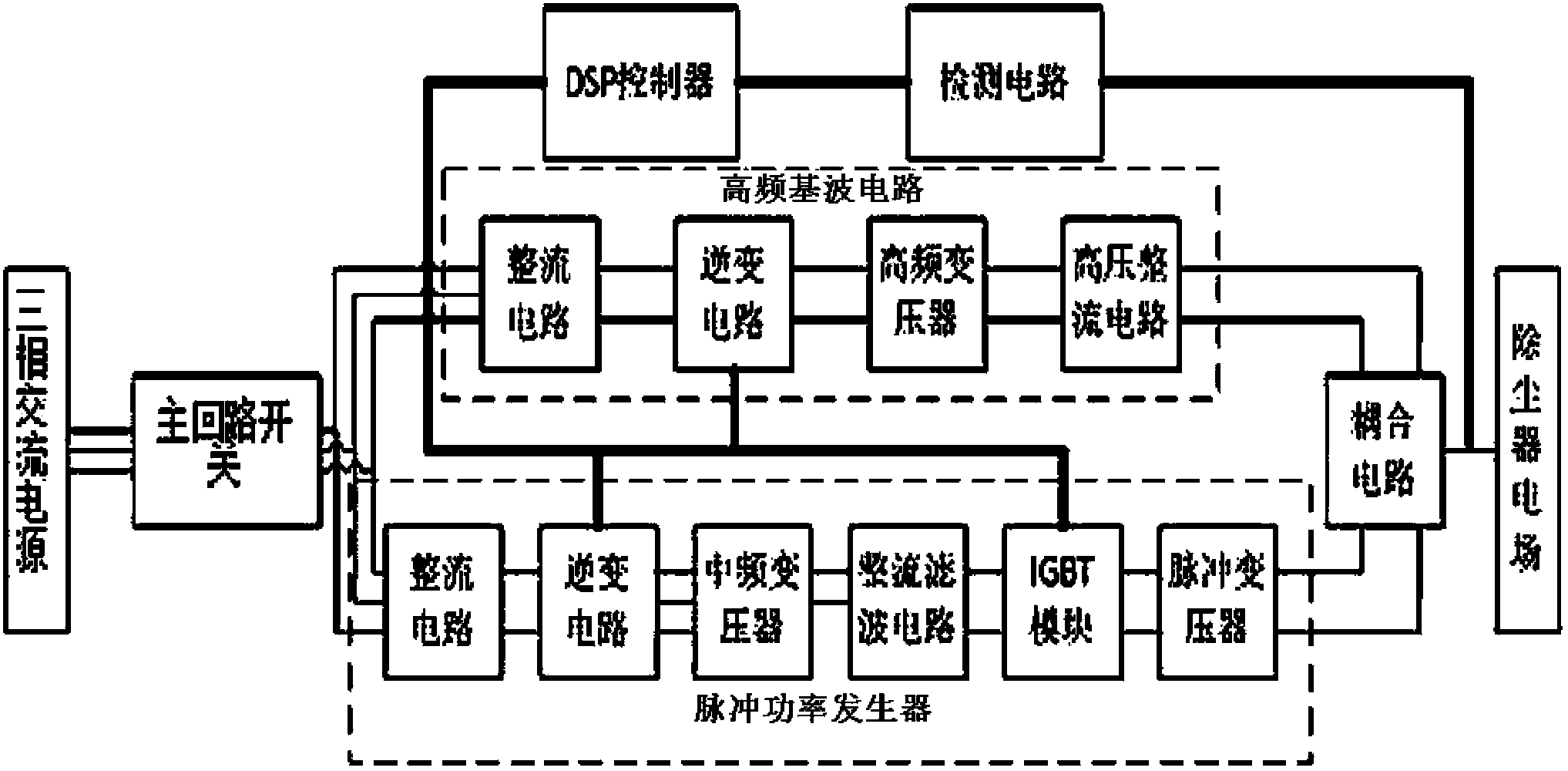

[0021] Example 1: Reference Figure 1~4 . A high-frequency pulse power supply for electric dust removal. A three-phase AC power supply is supplied to the electric field of the dust collector after passing through a high-frequency pulse power supply for electric dust removal. The characteristic is that the high-frequency pulse power supply for electric dust removal includes a main circuit switch, Pulse power generator, high frequency fundamental wave circuit, DSP controller, detection circuit, coupling circuit, pulse power generator, high frequency fundamental wave circuit are connected in parallel between the main loop switch and coupling circuit;

[0022] The main circuit switch is composed of a circuit breaker and a contactor connected in series, and the three-phase AC power is divided into two channels after the main circuit switch is supplied to the high-frequency fundamental wave circuit and the pulse power generator;

[0023] The pulse power generator is composed of a first ...

Embodiment 2

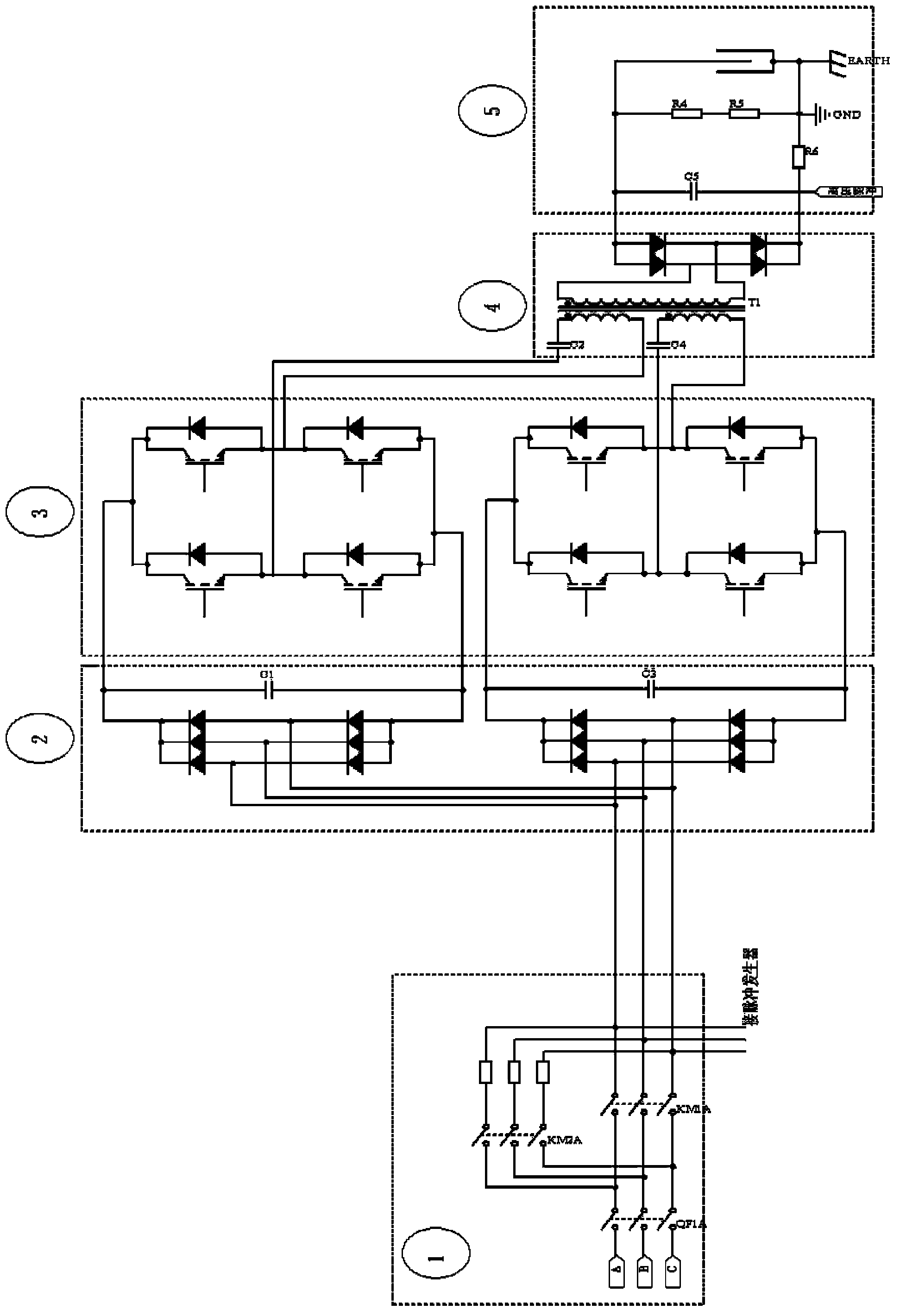

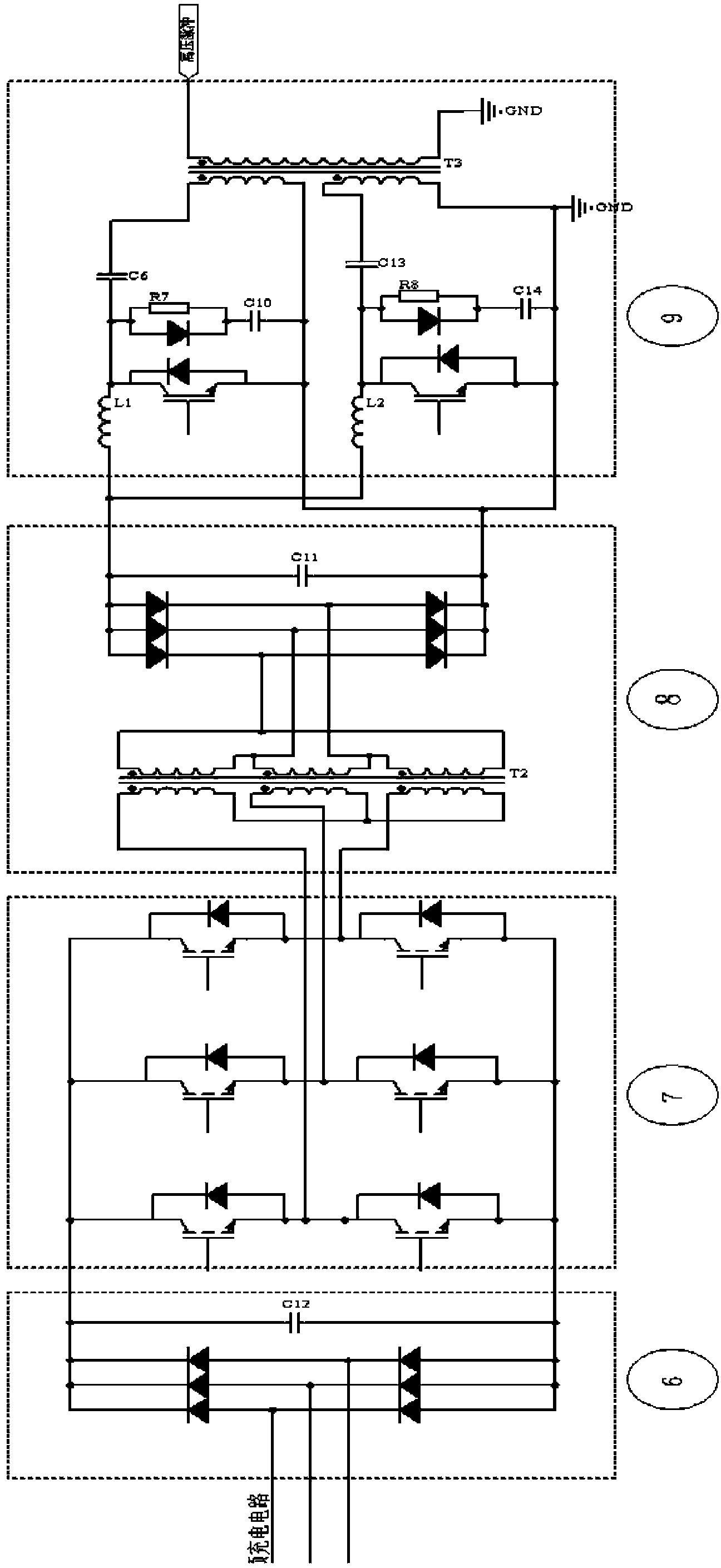

[0029] Example 2: Reference figure 2 with 3 . The principle of a high-frequency pulse power supply for electrostatic precipitator is as follows: the main circuit switch 1 is connected with a three-phase 380V / 50Hz AC power supply, the main circuit switch 1 is formed by a circuit breaker and a contactor in series, after the main circuit switch 1 is closed , The current flows into the high-voltage fundamental wave generator and pulse power generator in two parts A and B respectively. Part A: The triac circuit 2 is connected to the main circuit switch 1 and the three-phase power frequency transformer 3. The triac circuit 2 adopts an integrated triac structure, and the three-phase high voltage silicon rectifier 4 and the three-phase power frequency transformer The secondary of 3 is connected to the electrostatic precipitator 5. Part B: The triac circuit 6 is connected to the main circuit switch 1 and the three-phase power frequency transformer 7, the three-phase high voltage silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com