Controls for hybrid vehicles

A hybrid vehicle and control device technology, applied in hybrid vehicles, power devices, control devices, etc., can solve the problems of shifting shock, increase of input speed, and decrease of clutch torque capacity on the release side, etc., to achieve reliable transmission and suppress shifting shock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

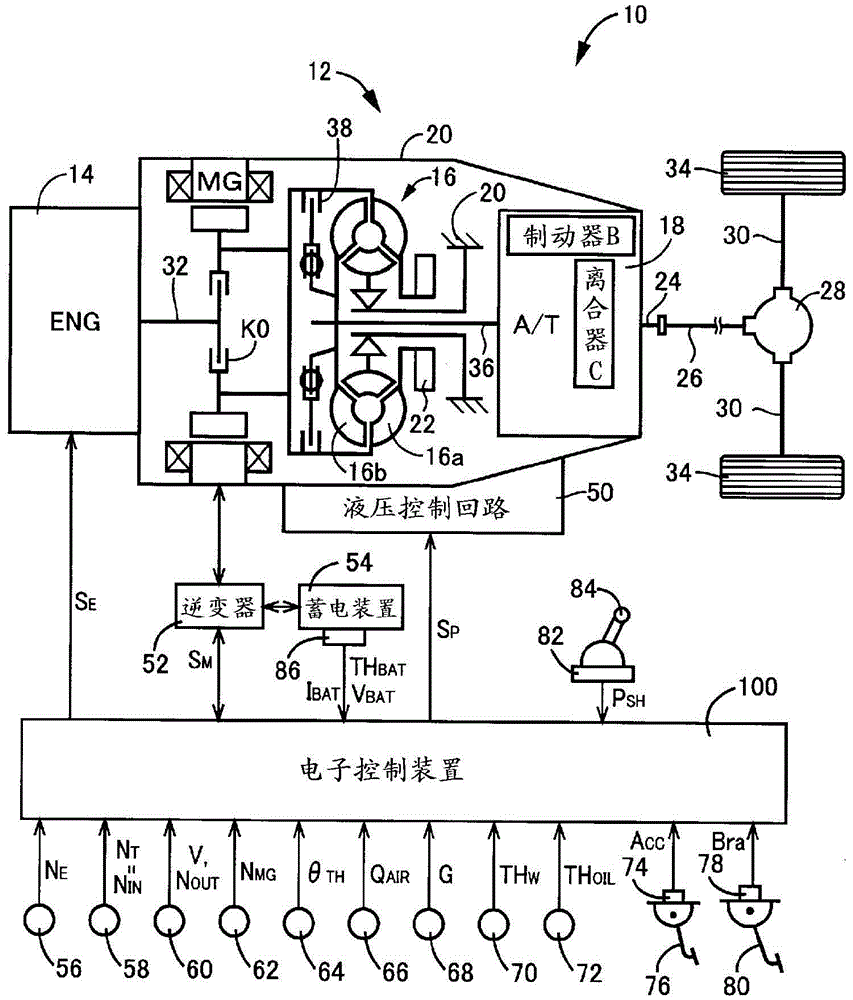

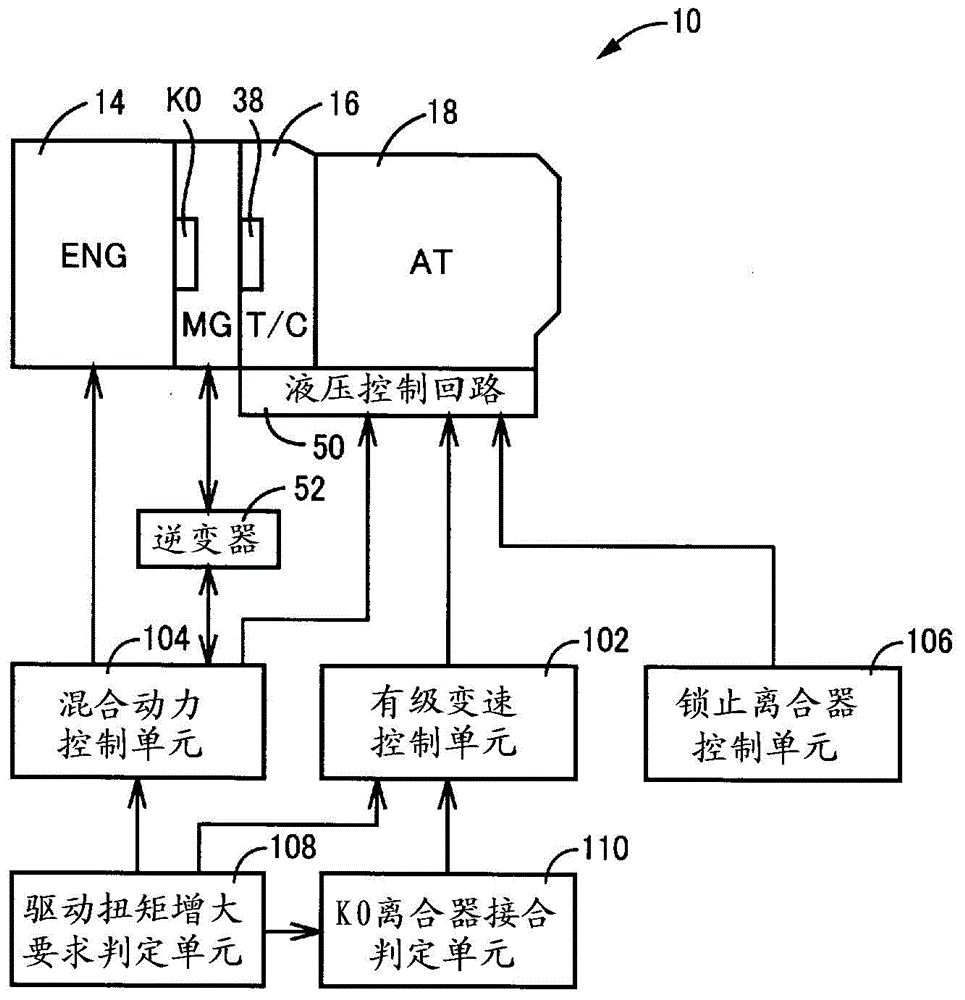

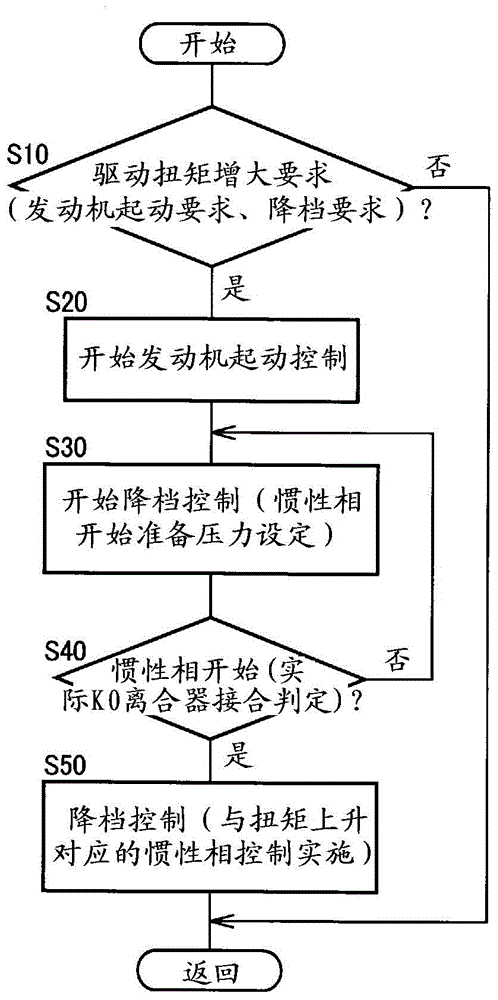

[0034] figure 1 It is a diagram illustrating a schematic structure of a power transmission path from the engine 14 to the driving wheels 34 constituting a hybrid vehicle 10 to which the present invention is applied (hereinafter, referred to as the vehicle 10 ), and is a diagram for realizing a driving force source for traveling. A diagram for explaining functions such as the output control of the engine 14 , the shift control of the automatic transmission 18 , the drive control of the electric motor MG, etc. are provided in the main part of the control system of the vehicle 10 .

[0035] figure 1 Among them, the power transmission device 12 for a vehicle (hereinafter referred to as the power transmission device 12 ) is installed in a transmission case 20 (hereinafter referred to as the case 20 ) as a non-rotating member mounted on the vehicle body by bolt fastening or the like, from The engine 14 side includes an engine disconnect clutch K0, an electric motor MG, a torque con...

Embodiment 2

[0071] In the foregoing Embodiment 1, the K0 clutch engagement determination unit 110 is based on the actual engine speed N E and the actual motor speed N MG The speed difference ΔN K0 (=N MG -N E ) to determine whether the engine disconnection clutch K0 is engaged, or based on the actual transmission input speed N IN Synchronous speed with before shifting N IN The speed difference ΔN of b IN (=N IN -N IN b) It is determined whether the inertia phase of the downshifting process of the automatic transmission 18 is started, thereby determining whether or not the clutch K0 for engine disconnection has been engaged. In this way, electric signals transmitted from various sensors are used in the determination of the completion of engagement of the engine disconnect clutch K0. Therefore, there is a communication delay depending on the electrical signal used, and there is a possibility that a determination delay may occur. Therefore, it is preferable to perform the determinat...

Embodiment 3

[0082] In the aforementioned first embodiment, in order to suppress the occurrence of the shock at the time of engine start by the hybrid control unit 104, the lock-up clutch control unit 106 controls the lock-up clutch 38 of the torque converter 16 to a released or slipping state. However, as described above, when the downshift control of the automatic transmission 18 is executed in addition to the engine start control, when the engagement of the engine disconnection clutch K0 is completed, the automatic transmission 18 is made to function as a torque limiter, thereby suppressing Engagement shock (synchronous shock) of the clutch K0 for engine disconnection at the time of engine start. Therefore, when the downshift control of the automatic transmission 18 is executed in addition to the engine start control, the lock-up clutch 38 of the torque converter 16 may be controlled to be in the fully engaged state (lockup-on state). Thereby, the transmission loss accompanying bringing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com