Thin seam gob-side entry retaining filling method

A technology of thin coal seam and road retaining, which is applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of large labor, complicated process, affecting the mining work, etc., and achieves the effect of convenient transportation and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

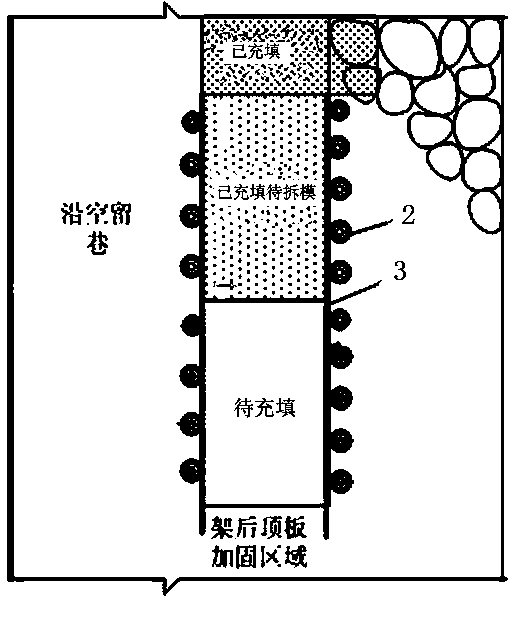

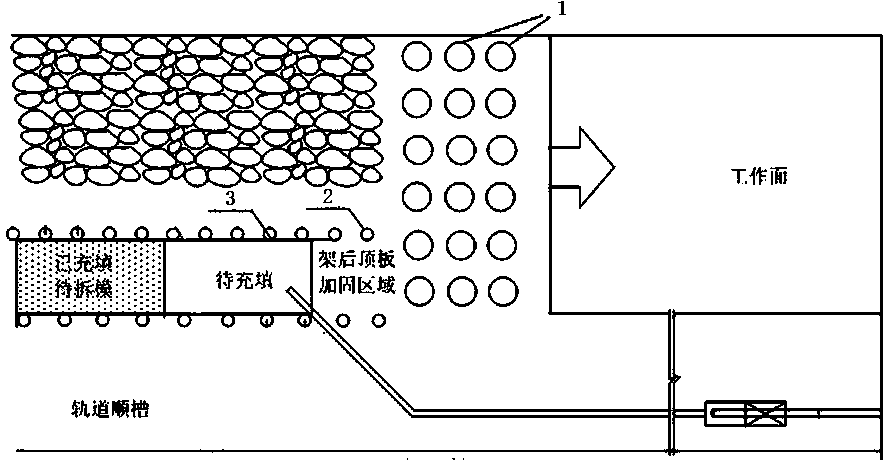

[0017] A thin coal seam filling method for gob-side entry retention according to the present invention, when the working face is mining and advancing, the side end support of the entry retention side of the working face is closely followed, and a single pillar is installed in the filling area of the entry retention to be retained, and the gangue is blocked. , according to the designed row spacing, construct the roof anchor in time; when the length to be filled behind the support reaches the filling step distance, install the round wood point column to replace the single support, and after the temporary support space reaches the filling length once, the inside of the round wood point column Nail the wooden boards, except for the filling openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com