Device for improving yield of methane produced from kitchen waste through anaerobic digestion and method for producing methane

A technology for kitchen waste and anaerobic digestion, which is applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc. The problem of high energy consumption in composting treatment can shorten the residence time, speed up the anaerobic digestion rate, and increase the amount of biogas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

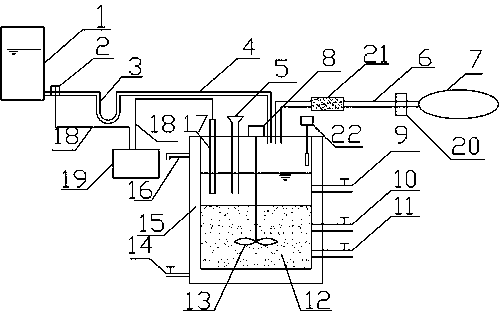

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0021] Such as figure 1 As shown, a device for increasing the amount of biogas produced by anaerobic digestion of food waste includes a complete mixing reaction chamber 12, and the upper part of the complete mixing reaction chamber 12 is respectively equipped with a pH electrode probe 17, a feed port 5, a motor 8, and an exhaust pipe 6 , liquid level sensor 22, the inside of complete mixing reaction chamber 12 is provided with the stirring paddle 13 that is connected with the transmission shaft of motor 8; On the upper end face of the mixing reaction chamber 12, the lye pipe 4 is connected in series with the U-shaped pipe 3, and the lye pipe 4 between the U-shaped pipe 3 and the lye tank 1 is provided with a solenoid valve 2, a pH electrode probe 17, and a solenoid valve 2 Connect with signal processing and controller 19 by electric wire 18 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com