Plug-flow type reactor and controlling method of biogas produced by utilizing cow dung

A reactor and plug-flow technology, which is applied in the field of plug-flow reactor and its regulation of biogas production by using cow dung, can solve the problems of high construction cost, low organic matter utilization rate and methane recovery rate, and low gas production. Achieve the effect of low operating cost, high gas production rate and high biogas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

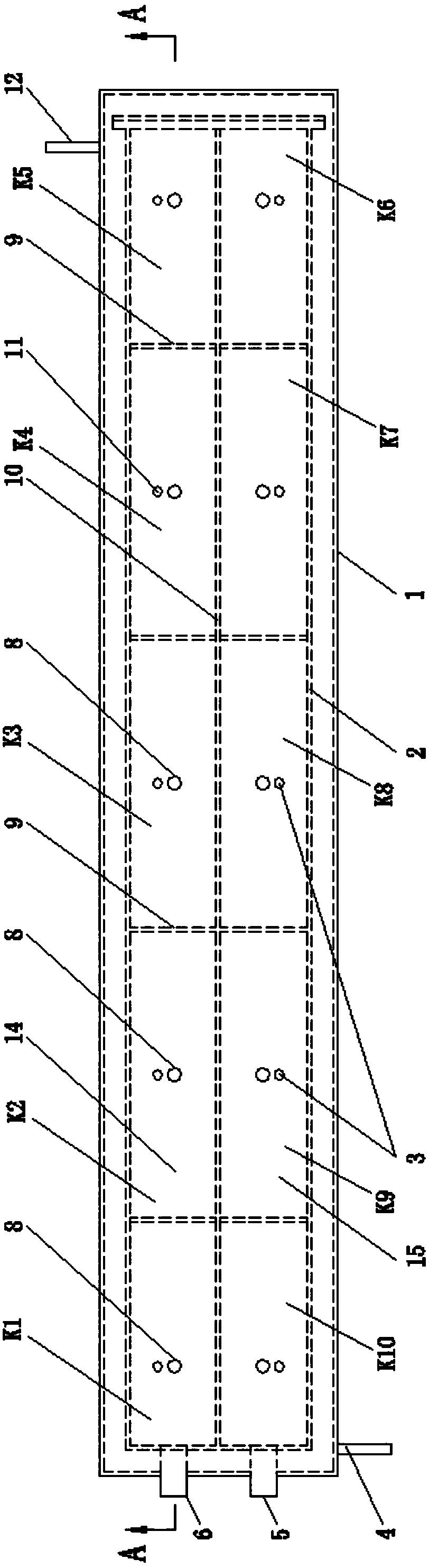

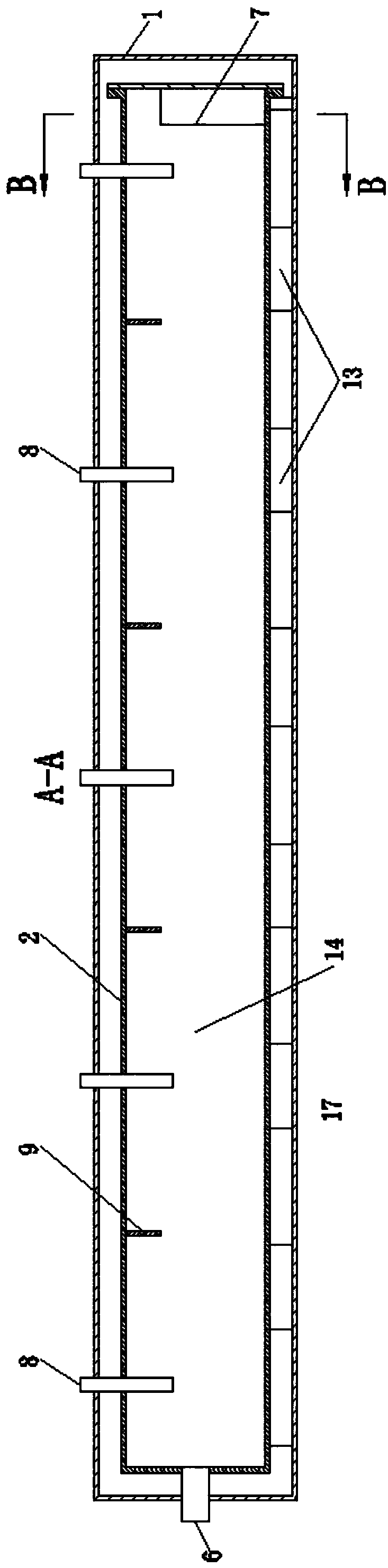

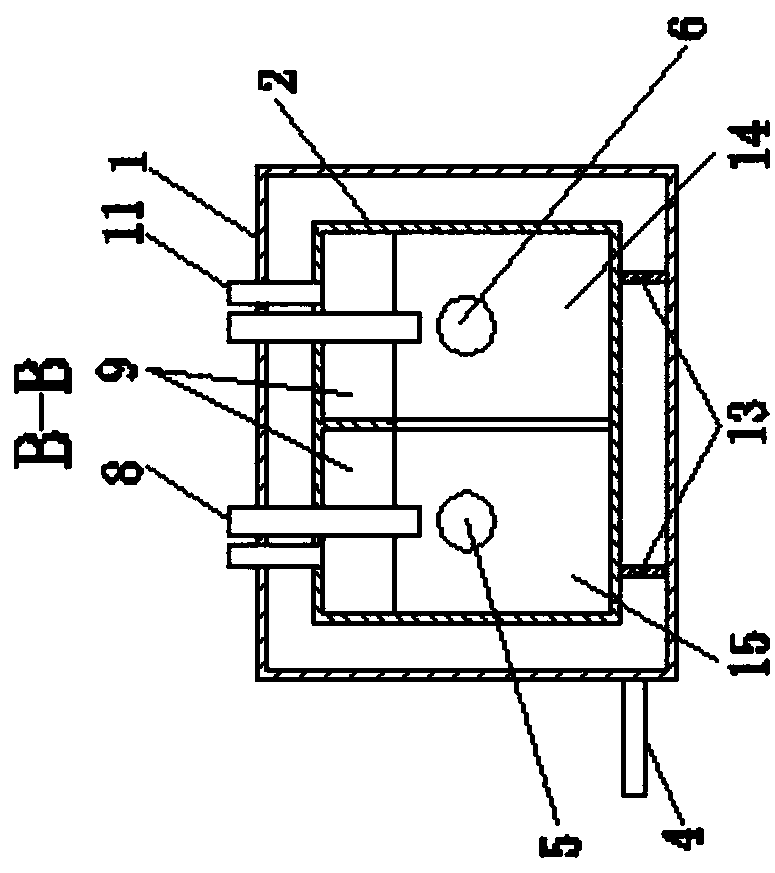

[0035] Specific implementation mode one: combine Figure 1-3 To illustrate, a plug-flow reactor in this embodiment is processed from plexiglass, including an outer box 1 and a main reactor 2, and the outer box 1 of the plug-flow reactor (PFR) is set In the main reactor 2, a cavity is formed between the outer box 1 and the main reactor 2, and hot circulating water is introduced into the cavity, and a support plate 13 is provided between the inner surface of the bottom of the outer box 1 and the main reactor 2;

[0036] Main reactor 2 length=1.5m, height=0.15m, width=0.2m;

[0037] In the main reactor 2, the first partition 10 is arranged perpendicular to the bottom plate of the main reactor 2 along the longitudinal direction to divide the main reactor 2 into a first reaction chamber 14 and a second reaction chamber 15; the first reaction chamber 14 and the second reaction chamber The upper part of the chamber 15 is divided into five air chambers by the second partitions 9 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com