Novel optical transparent adhesive tape gluing system

A technology of optical transparent adhesive and lamination system, which is applied in chemical instruments and methods, lamination devices, instruments, etc., can solve the problem of long debugging time of dispensing pattern and dispensing quantity, low production yield and low lamination efficiency. and other problems to achieve the effect of reducing process particle defects, improving optical effects, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

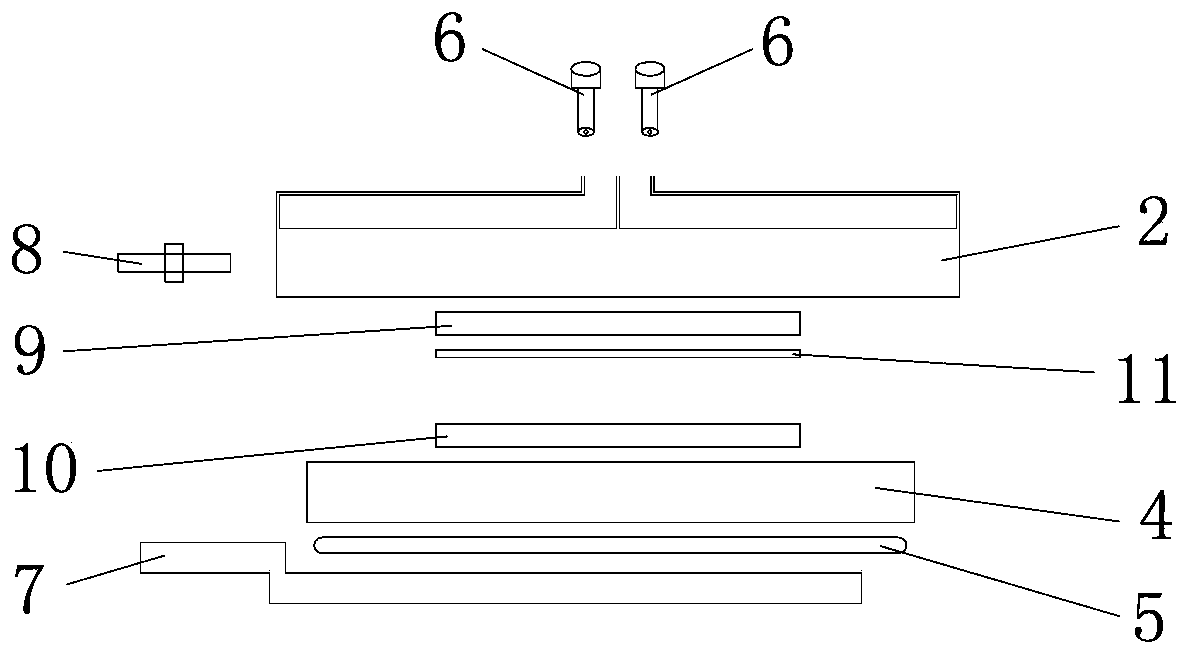

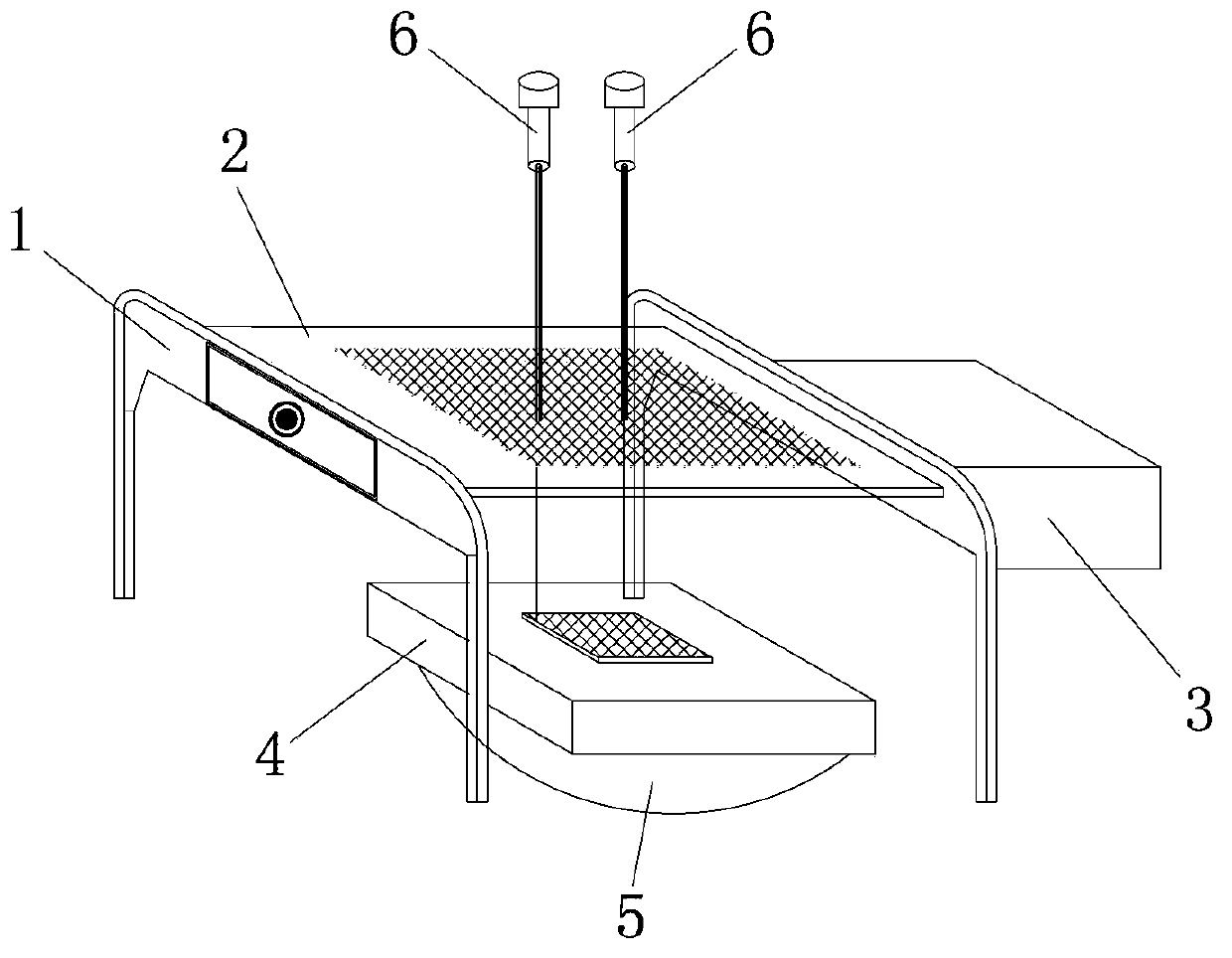

[0017] refer to figure 1 , figure 2 , a new type of optical transparent adhesive bonding system, including a machine 1, the machine is provided with a feeding manipulator, the feeding manipulator 7 is used to put the touch screen or glass cover on the upper platform 2 or the lower platform 4, or Remove the touch screen or glass cover from upper platform 2 or lower platform 4.

[0018] The machine table 1 is equipped with a horizontal upper platform 2 through a three-dimensional motion mechanism, and the upper platform 2 is connected with a power mechanism 3 that drives it to rotate. The three-dimensional motion mechanism is a precision action mechanism that moves along the X, Y, and Z axes. , it is suitable to be accurately controlled by a servo motor, and the three-dimensional motion mechanism is provided with an adjustment knob 8, which can manually adjust the position of the upper platform. The power mechanism 3 is a servo motor.

[0019] A horizontal lower platform 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com