A sliding feeding device

A sliding feeding and slideway technology, applied in the field of powder metallurgy devices, can solve the problems of difficult cleaning of peripheral burrs, affecting the surface quality of workpieces, and bonding to the surface of parts, so as to reduce work costs, provide cleanliness and quality, and reduce workpieces. The effect of scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

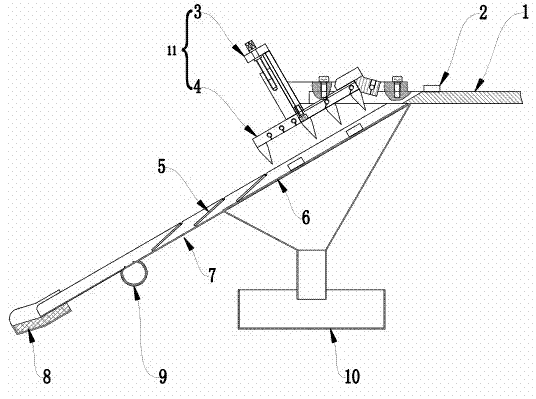

[0027] like Figure 1 to Figure 2 As shown, a sliding feeding device in this embodiment includes: a slideway 7, a burr cleaning structure 11 and a dust collection system.

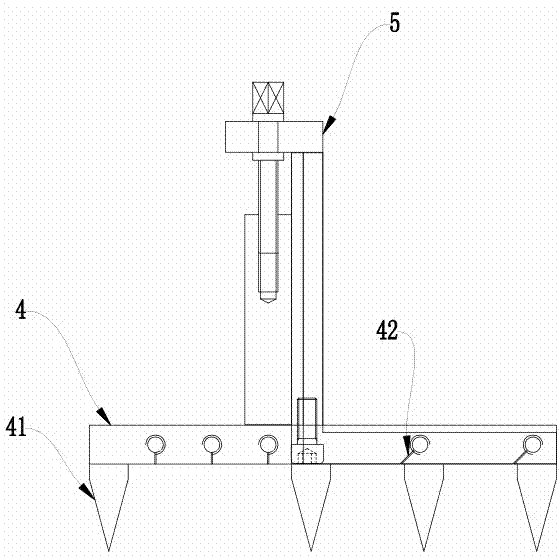

[0028] Slideway 7, said slideway 7 is fixed on the press stripper plate 1, and the working surface of the slideway 7 is connected with the working surface of the press stripper plate 1, the slideway 7 working surface has a certain slope, and the slideway 7 The upper part is provided with a slideway mesh plate 6, and the slideway mesh plate 6 is provided with a plurality of gap holes, and the middle part of the slideway 7 is provided with a plurality of sliding buffer mechanisms 5.

[0029] The slideway 7 with inclined plane design makes the workpiece 2 slide down by its own weight, and the burrs and dust that fall when the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com