Engaging element forming device for zipper and engaging element for zipper

A component and meshing technology, applied in the direction of fastener components, sliding fastener components, fasteners, etc., can solve the problems of unsmooth opening and closing of sliders, poor touch, etc., and achieve the effect of simple shape, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be specifically described based on the drawings.

[0035] The illustrated embodiment is a shaped implant applying the present invention to an engaging element for a slide fastener. Of course, the present invention is not limited to the shaping implantation device, and can also be applied to, for example, an engaging element forming device that does not implant the engaging elements formed one by one into a fastener tape, but is temporarily recovered, or is applied to a device having a forming mechanism other than the above-mentioned devices. , All devices in which engaging elements are formed from metal wire.

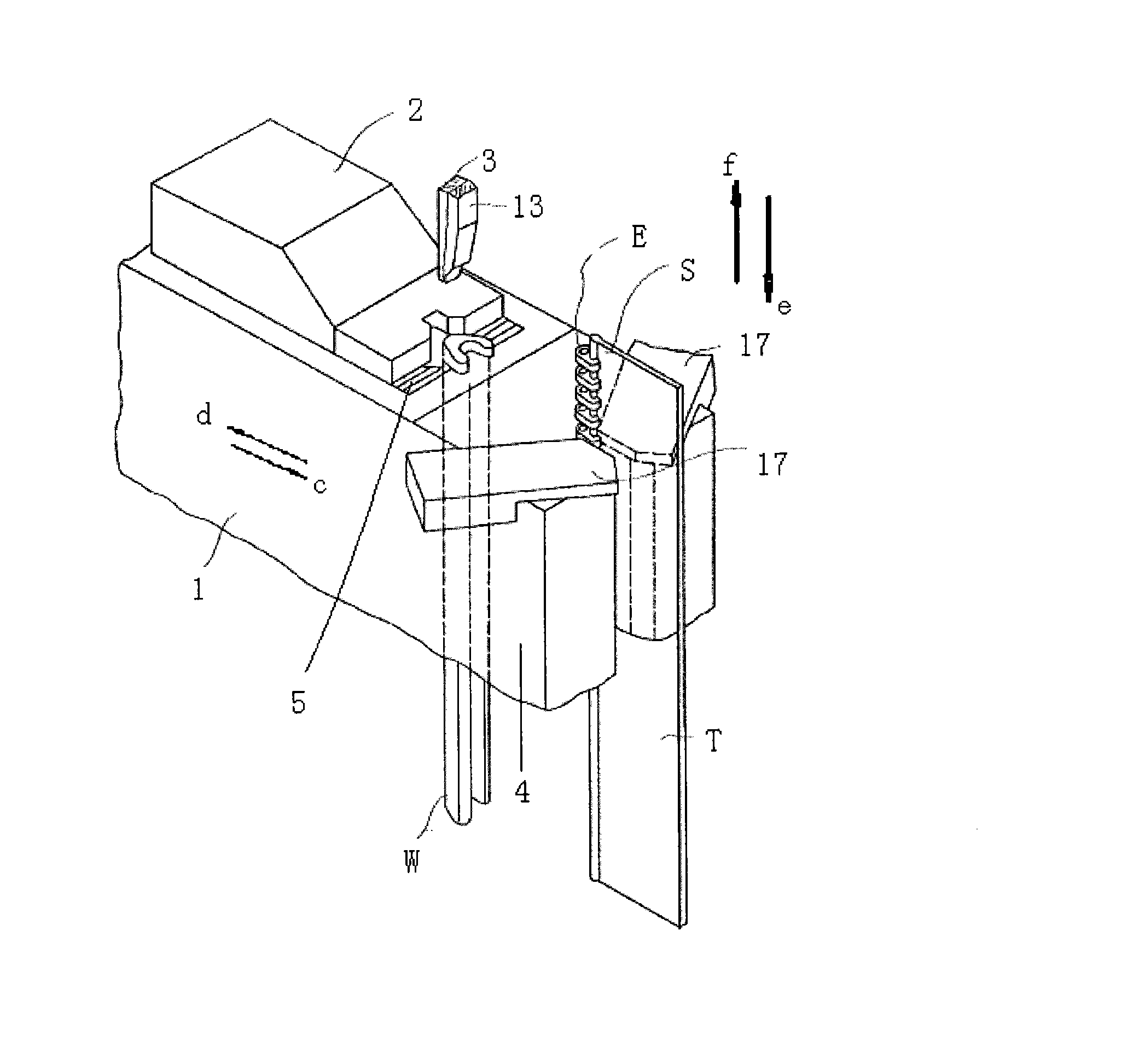

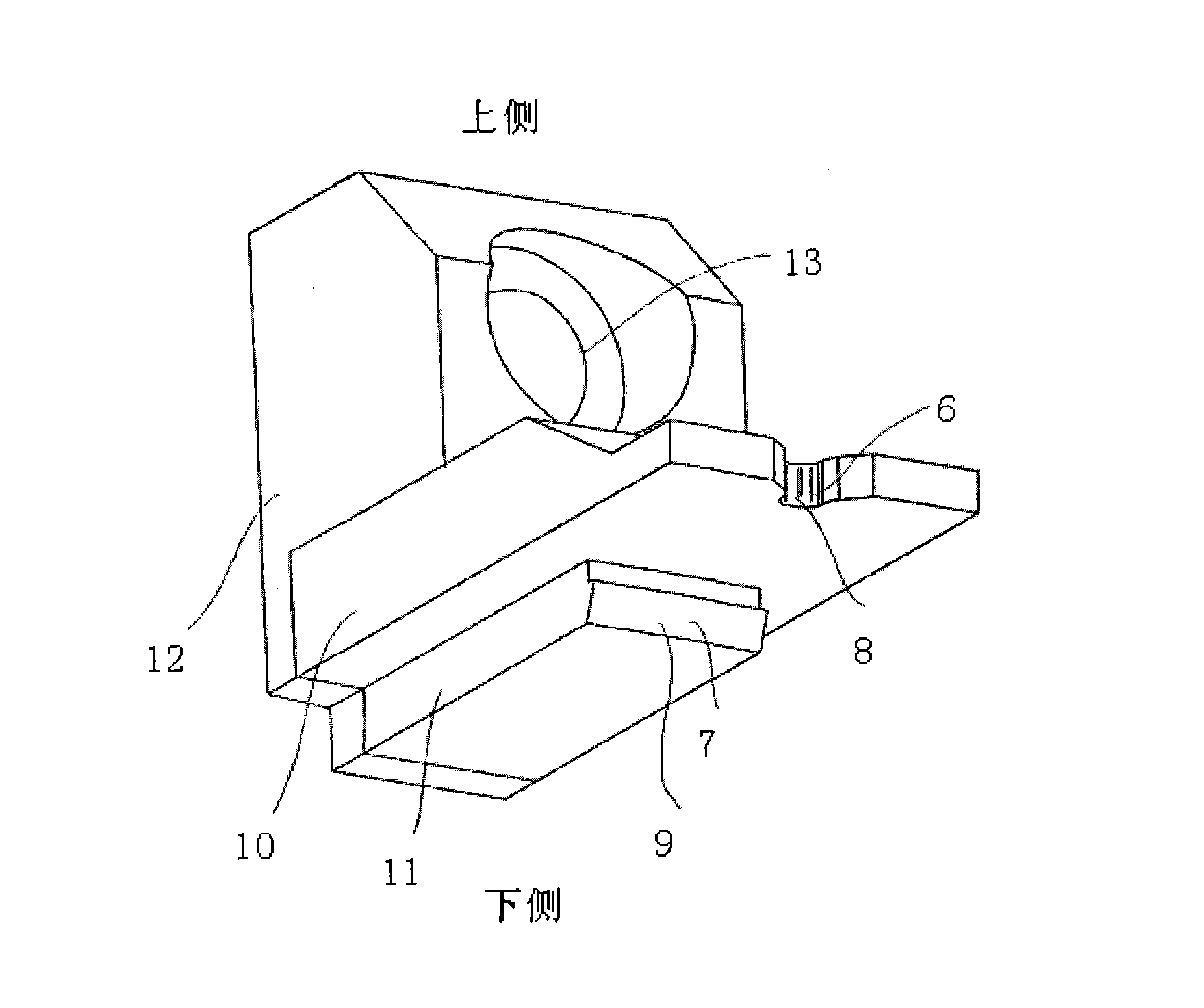

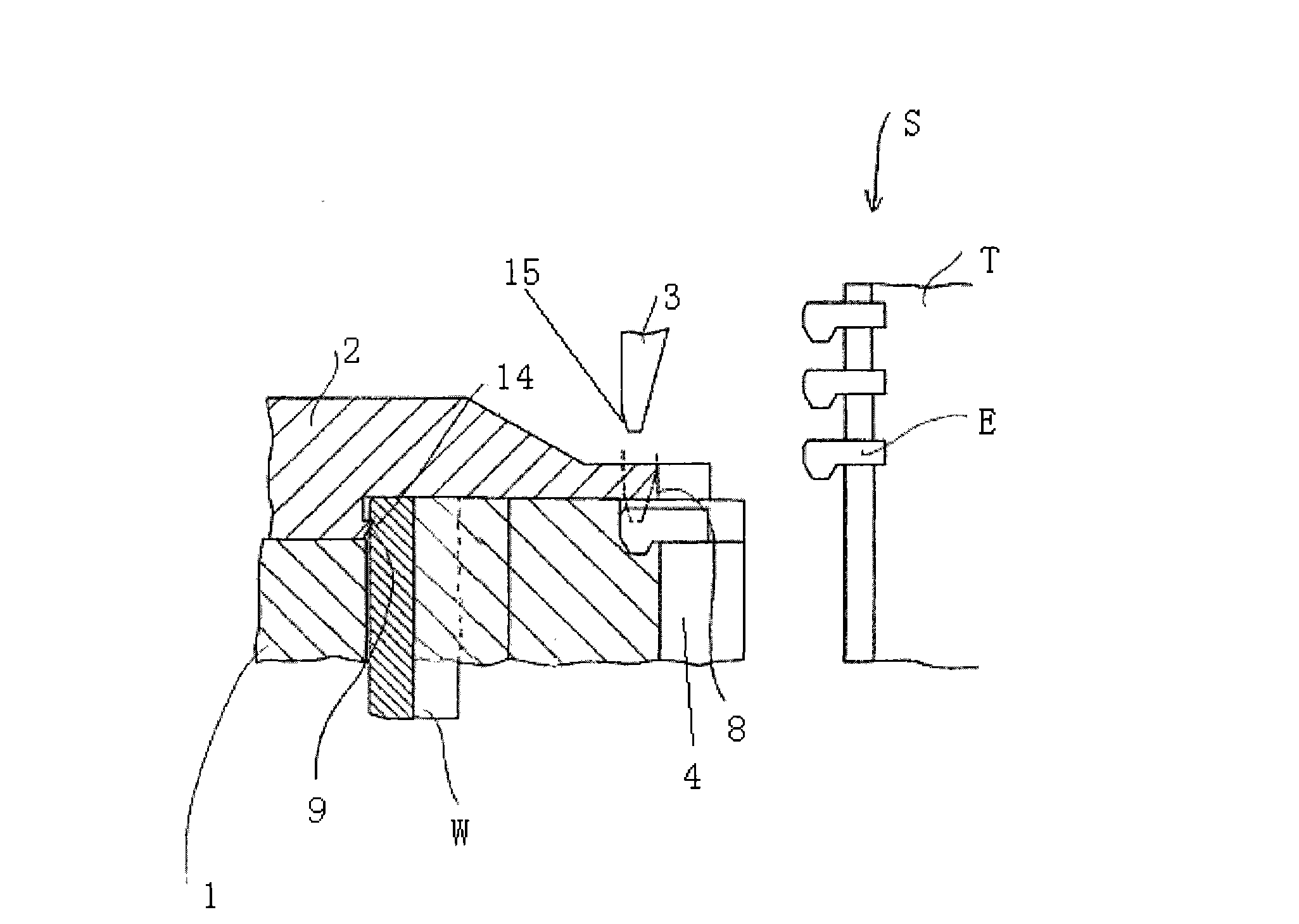

[0036] figure 1 It is a perspective view of the continuous manufacturing apparatus of the fastener stringer of the present invention, and the cutting die 1 arranged on the not-shown hammer is supported so as to be freely reciprocable in the directions of arrows c and d via a not-shown guide mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com