Production method of superfine slag powder

A production method and slag micropowder technology, applied in the field of building materials, can solve the problems of unstable quality, low production efficiency, low qualification rate, etc., and achieve the effects of reducing energy consumption, high production efficiency, and high qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

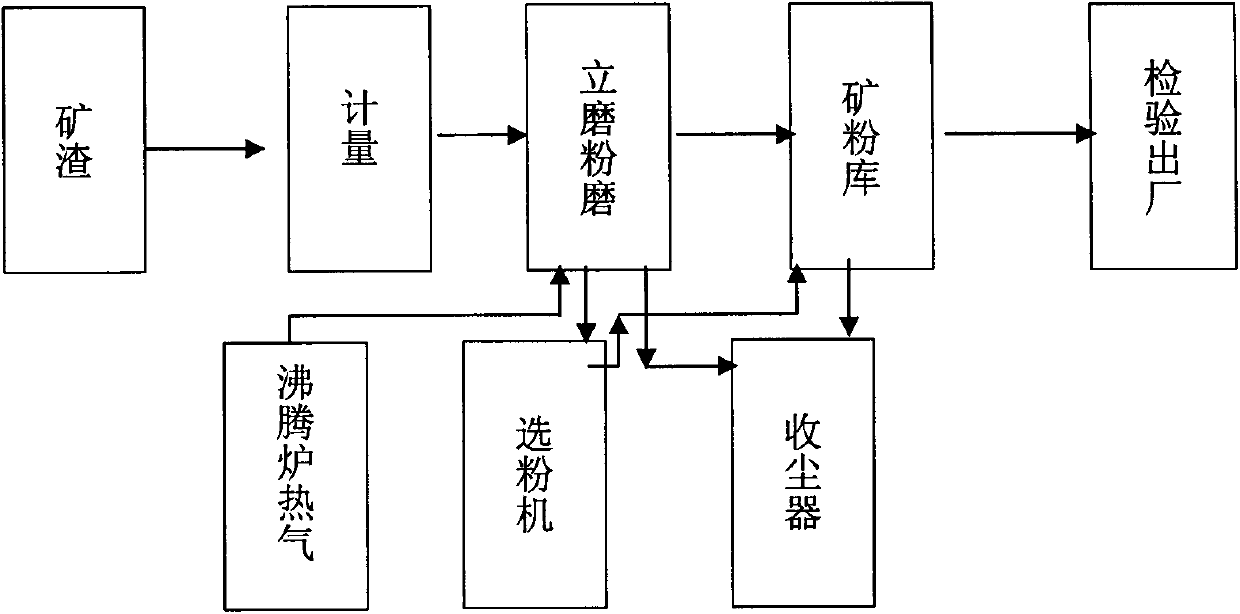

[0012] As shown in Figure 1, the slag enters the vertical mill after being metered. While grinding, the hot air from the fluidized fluidized furnace flows into the vertical mill. The temperature of the hot air is controlled between 230-280°C, and the slag It is crushed under the action of the pressure roller of the vertical mill, and at the same time, under the continuous drive of the centrifugal force, the slag moves to the outer edge of the grinding table, and the slag leaving the grinding table encounters the hot gas in the vertical mill and rises accordingly. The middle casing of the vertical mill enters the separator, during which the slag and the hot air have fully exchanged heat, and the water is evaporated quickly, only those particles that are enough to be carried by the wind can reach the upper separator, and then pass through the separation Powder selection by powder machine, specific surface area ≥ 400m 2 / Kg of fine powder enters the ore powder storehouse, and coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com