Seabuckthorn-snow daisy fruit vinegar beverage and preparation method thereof

A technology of seabuckthorn snow chrysanthemum and seabuckthorn fruit, which is applied in the preparation of vinegar, food preparation, food science, etc., can solve the problems of low conversion rate, slow production rate of fruit vinegar, and long fermentation cycle, so as to accelerate growth and promote yield , the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

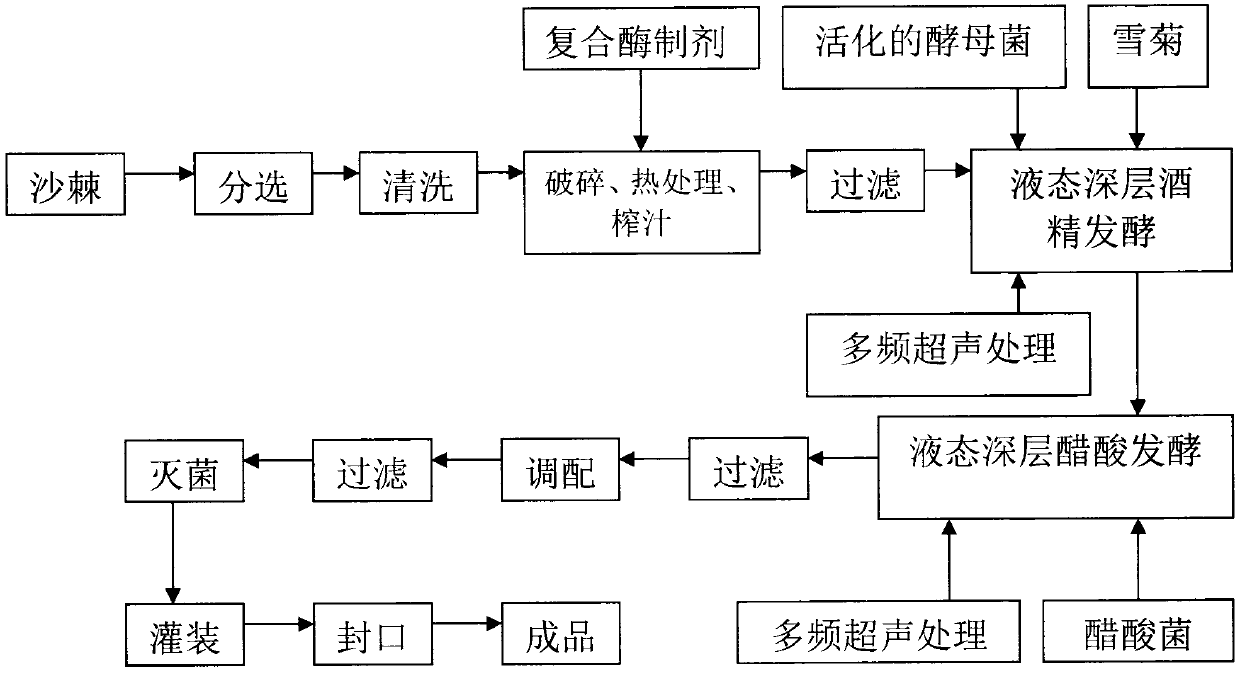

[0042] Example 1: Preparation of Seabuckthorn Snow Chrysanthemum Fruit Vinegar Drink

[0043] Specifically, the present invention utilizes compound enzymatic hydrolysis and juicing technology, multi-frequency ultrasonically enhanced high-efficiency liquid state staged fermentation technology, and fermentation synchronous extraction technology to prepare seabuckthorn snow chrysanthemum fruit vinegar drink. The specific preparation method steps are as follows:

[0044] (1) Sorting: select fully mature seabuckthorn fruits, remove pests, mildew, rotten fruits, leaves, branches and other impurities.

[0045] (2) Cleaning: Rinse the above-mentioned sorted seabuckthorn fruits with running water.

[0046] (3) Broken: crush with a crusher or a beater, and remove the peel and core of the seabuckthorn fruit cleaned in step (2).

[0047] (4) Heat treatment: heat the seabuckthorn pulp after the crushing step (3), the heat treatment temperature is 50-70° C., and the time is 10-20 minutes. ...

Embodiment 2

[0056] Example 2: Preparation of Seabuckthorn Snow Chrysanthemum Fruit Vinegar Drink

[0057] (1) Sorting: select fully mature seabuckthorn fruits, remove pests, mildew, rotten fruits, leaves, branches and other impurities.

[0058] (2) Cleaning: Rinse the above-mentioned sorted seabuckthorn fruits with running water.

[0059] (3) Broken: crush with a crusher or a beater, and remove the peel and core of the seabuckthorn fruit cleaned in step (2).

[0060] (4) Heat treatment: heat the seabuckthorn pulp after the crushing step (3), the heat treatment temperature is 50° C., and the time is 20 minutes.

[0061](5) Enzyme treatment, juicing: adopt the compound enzymolysis method that is made up of pectinase and cellulase to carry out the enzyme treatment of seabuckthorn pulp; the seabuckthorn pulp prepared by the above step (4) is placed in an enzymolysis tank, and Adjust the temperature to 20°C, adjust the pH value to 2.5 with NaOH or HCL, add the compound enzyme preparation to ...

Embodiment 3

[0068] Example 3: Preparation of Seabuckthorn Snow Chrysanthemum Fruit Vinegar Drink

[0069] (1) Sorting: select fully mature seabuckthorn fruits, remove pests, mildew, rotten fruits, leaves, branches and other impurities.

[0070] (2) Cleaning: Rinse the above-mentioned sorted seabuckthorn fruits with running water.

[0071] (3) Broken: crush with a crusher or a beater, and remove the peel and core of the seabuckthorn fruit cleaned in step (2).

[0072] (4) Heat treatment: heat the crushed seabuckthorn pulp in step (3), the heat treatment temperature is 60° C., and the heat treatment time is 15 minutes.

[0073] (5) Enzyme treatment, juicing: adopt the compound enzymolysis method that is made up of pectinase and cellulase to carry out the enzyme treatment of seabuckthorn pulp; the seabuckthorn pulp prepared by the above step (4) is placed in an enzymolysis tank, and Adjust the temperature to 35°C, adjust the pH value to 3.5 with NaOH or HCL, add the compound enzyme prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com