Aluminum alloy shaped wire photoelectric composite cable

A technology for optoelectronic composite cables and aluminum alloys, applied in power cables, cables, circuits, etc., can solve problems such as increased use and construction costs, construction difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with the best embodiment 。

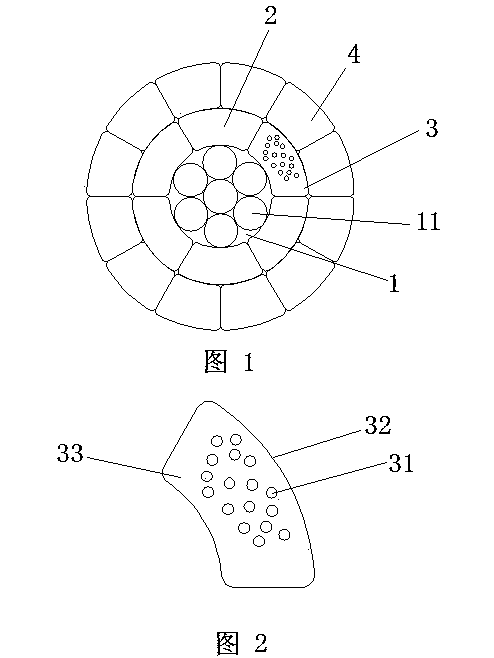

[0011] Such as figure 1 As shown in Figure 2, the present invention is an aluminum alloy type wire photoelectric composite cable, including a core wire 1, the core wire 1 is formed by twisting several galvanized steel strands 11, and the core wire 1 is concentrically twisted with A plurality of trapezoidal aluminum alloy single wires 2 and a trapezoidal light unit 3 , and several fan-shaped aluminum alloy single wires 4 are concentrically twisted outside the trapezoidal aluminum alloy single wires 2 and the trapezoidal light unit 3 . The trapezoidal optical unit 3 is provided with 24-core optical fiber 31 , and the outer surface of the optical fiber 31 is provided with a stainless steel sleeve 32 , and a water-blocking ointment 33 is filled between the optical fiber 31 and the stainless steel sleeve 32 .

[0012] The aluminum alloy profiled wire photoelectric composite cable in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com