Crease-resist cloth rolling machine

A cloth rolling machine and cloth guide roller technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of cloth wrinkling caused by the rotation of the cloth guide roller, affecting the dyeing effect and quality of the cloth, and prevents the cloth Damage, prevent wrinkles, and prevent excessive negative pressure and suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

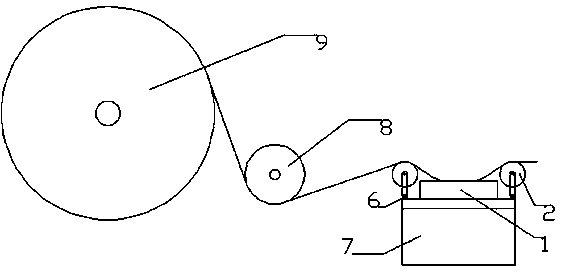

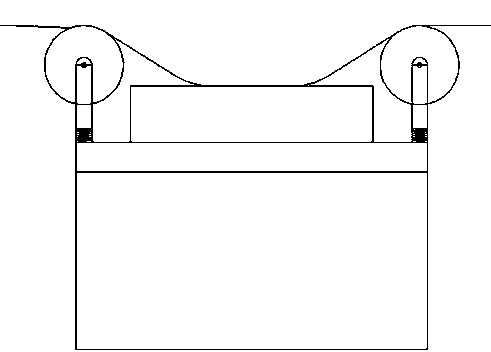

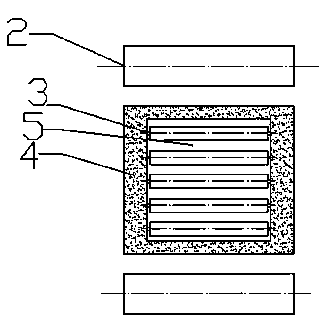

[0021] Such as figure 1 , image 3 As shown, the present invention includes a cloth leveler, a leading cloth roll 8 and a cloth roll 9, and the cloth passes through the cloth leveler and winds on the cloth roll 9 via the leading cloth roll 8, wherein the cloth leveler includes an operating table 1, two secondary cloth guide rolls 2, wherein the operating table 1 includes a supporting area 4 and a vacuum pulling area 5, and two secondary fabric guide rollers 2 are symmetrically arranged on both sides of the operating table 1, and the cloth passes through the supporting area 4 and the vacuum pulling area through the two secondary cloth guiding rollers 5. Leveling by vacuuming, wherein the vacuum pulling area 5 is also equipped with a number of auxiliary cloth guide rollers 3 wrapped with silica gel. Usually, the force is uniform, and at the same time, springs 6 are arranged at the connection between the two secondary cloth guide rollers 2 and the outer shell 7, so as to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com