Process for separation of a mixture containing a microbial substance and a liquid

A technology of microorganisms and mixtures, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high energy consumption, non-continuous operation, clogging of filters and regular maintenance, and achieve the effect of reduced energy consumption and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

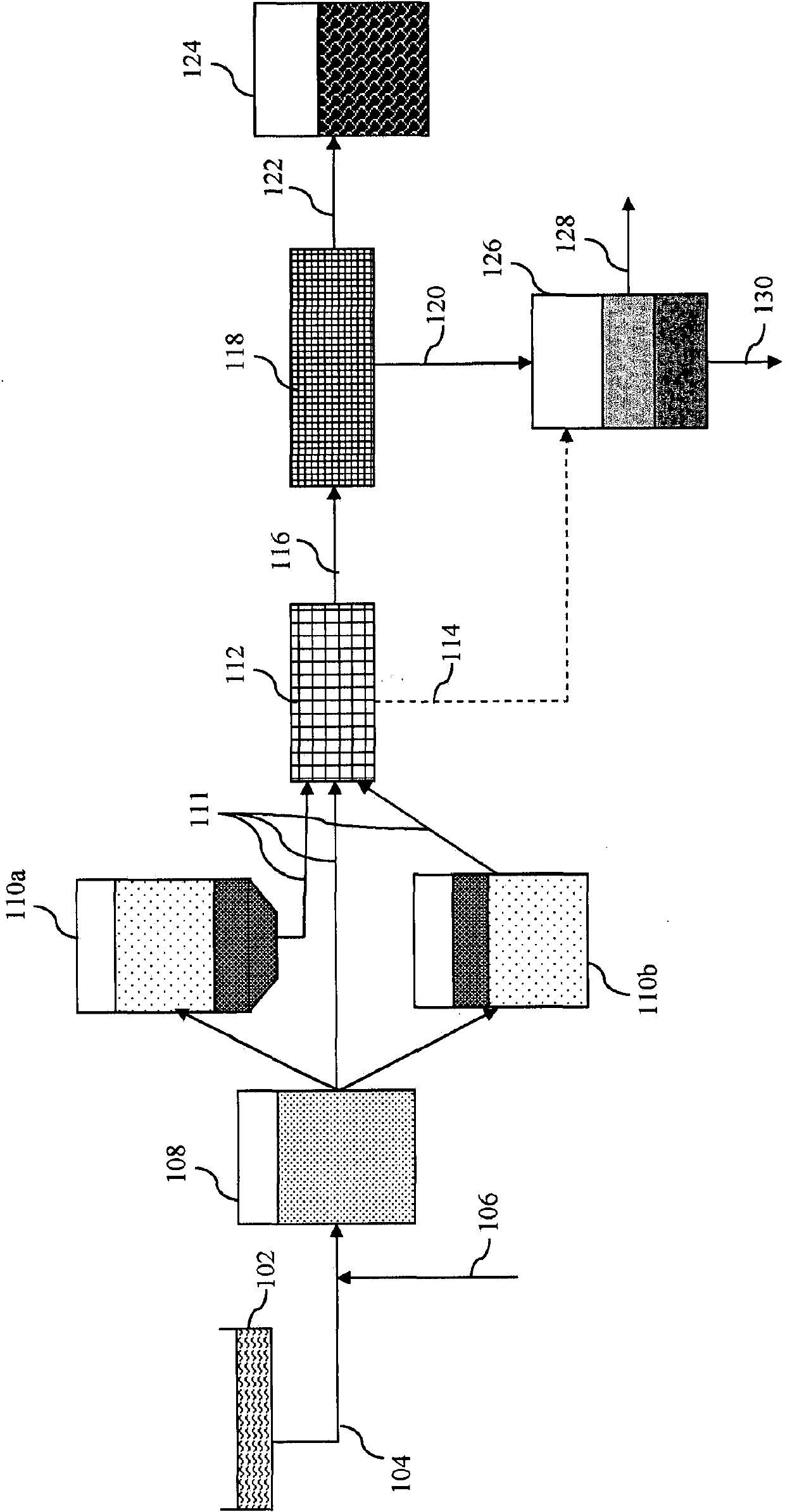

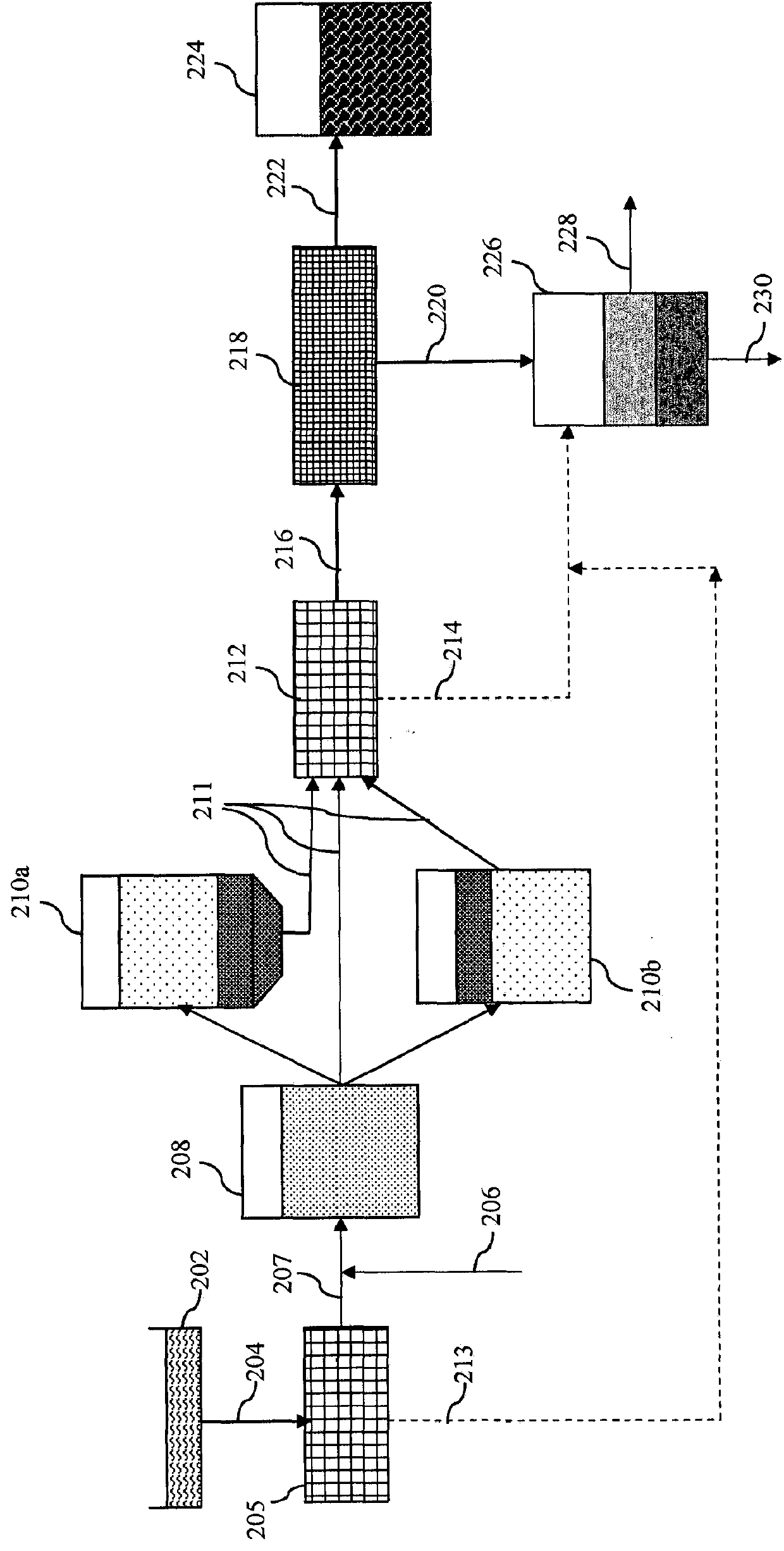

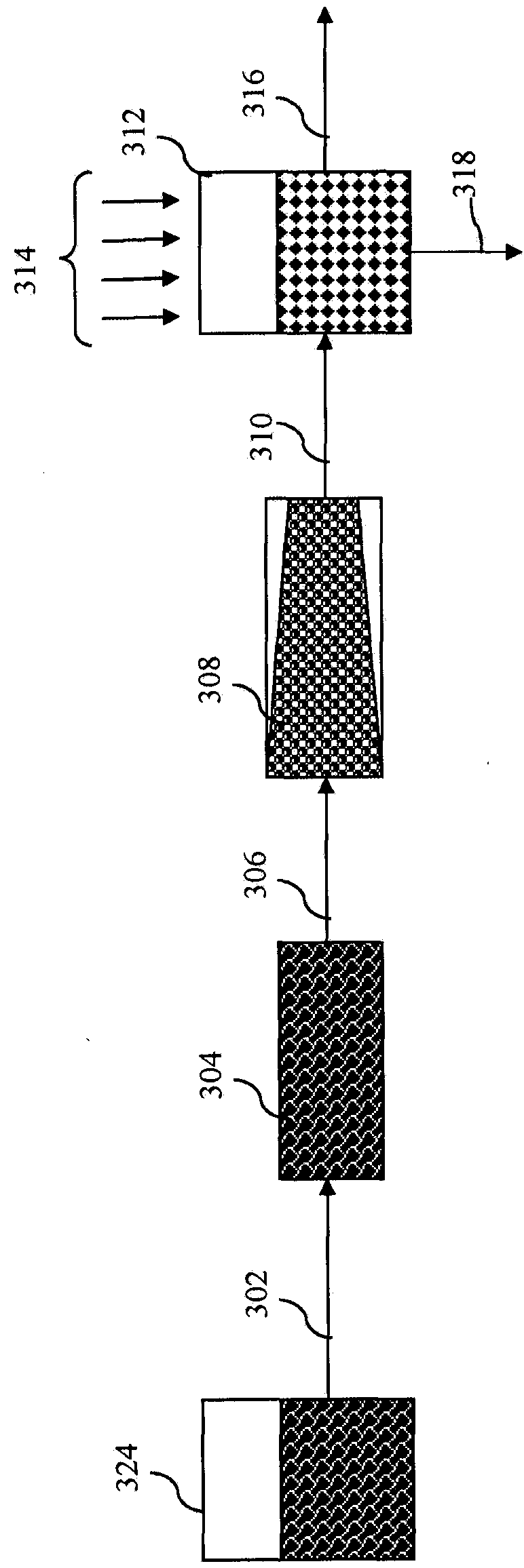

Method used

Image

Examples

Embodiment 1

[0170] About 760 kg of an aqueous mixture comprising diatoms and having a dry matter content of about 1 wt % (based on the total weight of the mixture) was coagulated and flocculated using 10 ppmw of flocculant (Nalco 71303) to produce coagulated and flocculated water and algae of the slurry. The slurry was sent via a peristaltic pump to a dissolved air flotation (DAF) unit where air was blown into the slurry at a flow rate of 5 l / min (=20 NL / min) at a pressure of 4 bar. A concentrated aqueous slurry is skimmed from the top of the mixture in the DAF unit. The concentrated aqueous slurry has a dry matter content of about 4 wt%, based on the total weight of the slurry. About 25 kg of this concentrated aqueous slurry was then sent to a pre-filtration unit comprising a polymeric filter with a pore size of about 170 μm. This slurry is then sent to a deformable filter located in a so-called dynamic belt filter press. The deformable filter comprises a polypropylene filter with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com